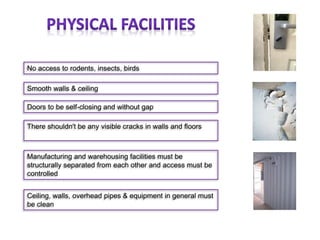

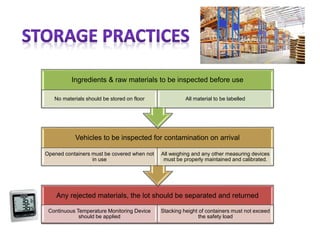

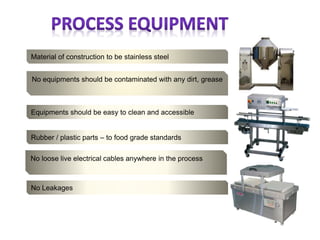

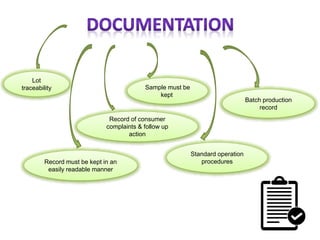

The document outlines various control measures and procedures for food production facilities including personnel hygiene, facility requirements, storage practices, sanitation processes, equipment standards, and documentation. Key areas addressed are restricting access to pests, maintaining clean walls and ceilings without cracks, separating manufacturing and storage areas with controlled access, ensuring clean ceilings, walls and equipment, and proper temperature monitoring, storage, inspection of ingredients and materials. Documentation requirements include batch records, lot traceability, complaint records and sample retention.