Desulfurization 2

•Download as PPTX, PDF•

10 likes•6,466 views

What is Desulfurization

Report

Share

Report

Share

Recommended

Achieving the target set during COP21 will require the deployment of a diverse portfolio of solutions, including fuel switching, improvements in energy efficiency, increasing use of nuclear and renewable power, as well as carbon capture and storage (CCS).

It is in the context of CCS that carbon capture and utilisation (CCU), or conversion (CCC), is often mentioned. Once we have captured and purified the CO2, it is sometimes argued that we should aim to convert the CO2 to useful products such as fuels or plastics, or otherwise use the CO2 in processes such as enhanced oil recovery (CO2-EOR). This is broadly referred to as CCU.

In this webinar, Niall Mac Dowell, Senior Lecturer (Associate Professor) in the Centre for Process Systems Engineering and the Centre for Environmental Policy at Imperial College London, presented about the scale of the challenge associated with climate change mitigation and contextualise the value which CO2 conversion and utilisation options can provide.Perspectives on the role of CO2 capture and utilisation (CCU) in climate chan...

Perspectives on the role of CO2 capture and utilisation (CCU) in climate chan...Global CCS Institute

More Related Content

What's hot

Achieving the target set during COP21 will require the deployment of a diverse portfolio of solutions, including fuel switching, improvements in energy efficiency, increasing use of nuclear and renewable power, as well as carbon capture and storage (CCS).

It is in the context of CCS that carbon capture and utilisation (CCU), or conversion (CCC), is often mentioned. Once we have captured and purified the CO2, it is sometimes argued that we should aim to convert the CO2 to useful products such as fuels or plastics, or otherwise use the CO2 in processes such as enhanced oil recovery (CO2-EOR). This is broadly referred to as CCU.

In this webinar, Niall Mac Dowell, Senior Lecturer (Associate Professor) in the Centre for Process Systems Engineering and the Centre for Environmental Policy at Imperial College London, presented about the scale of the challenge associated with climate change mitigation and contextualise the value which CO2 conversion and utilisation options can provide.Perspectives on the role of CO2 capture and utilisation (CCU) in climate chan...

Perspectives on the role of CO2 capture and utilisation (CCU) in climate chan...Global CCS Institute

What's hot (20)

Episode 3 : Production of Synthesis Gas by Steam Methane Reforming

Episode 3 : Production of Synthesis Gas by Steam Methane Reforming

CO2 to fuels and chemicals course material final version

CO2 to fuels and chemicals course material final version

Calculation of an Ammonia Plant Energy Consumption:

Calculation of an Ammonia Plant Energy Consumption:

Perspectives on the role of CO2 capture and utilisation (CCU) in climate chan...

Perspectives on the role of CO2 capture and utilisation (CCU) in climate chan...

Similar to Desulfurization 2

Similar to Desulfurization 2 (20)

More from Kareem Tharaa

More from Kareem Tharaa (13)

Recently uploaded

Recently uploaded (20)

Kuwait City MTP kit ((+919101817206)) Buy Abortion Pills Kuwait

Kuwait City MTP kit ((+919101817206)) Buy Abortion Pills Kuwait

Learn the concepts of Thermodynamics on Magic Marks

Learn the concepts of Thermodynamics on Magic Marks

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Tamil Call Girls Bhayandar WhatsApp +91-9930687706, Best Service

Tamil Call Girls Bhayandar WhatsApp +91-9930687706, Best Service

A CASE STUDY ON CERAMIC INDUSTRY OF BANGLADESH.pptx

A CASE STUDY ON CERAMIC INDUSTRY OF BANGLADESH.pptx

Bhubaneswar🌹Call Girls Bhubaneswar ❤Komal 9777949614 💟 Full Trusted CALL GIRL...

Bhubaneswar🌹Call Girls Bhubaneswar ❤Komal 9777949614 💟 Full Trusted CALL GIRL...

DC MACHINE-Motoring and generation, Armature circuit equation

DC MACHINE-Motoring and generation, Armature circuit equation

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

HAND TOOLS USED AT ELECTRONICS WORK PRESENTED BY KOUSTAV SARKAR

HAND TOOLS USED AT ELECTRONICS WORK PRESENTED BY KOUSTAV SARKAR

Desulfurization 2

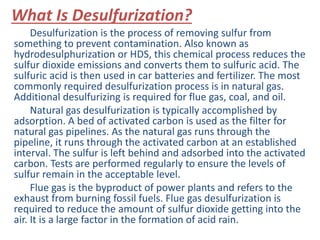

- 1. What Is Desulfurization? Desulfurization is the process of removing sulfur from something to prevent contamination. Also known as hydrodesulphurization or HDS, this chemical process reduces the sulfur dioxide emissions and converts them to sulfuric acid. The sulfuric acid is then used in car batteries and fertilizer. The most commonly required desulfurization process is in natural gas. Additional desulfurizing is required for flue gas, coal, and oil. Natural gas desulfurization is typically accomplished by adsorption. A bed of activated carbon is used as the filter for natural gas pipelines. As the natural gas runs through the pipeline, it runs through the activated carbon at an established interval. The sulfur is left behind and adsorbed into the activated carbon. Tests are performed regularly to ensure the levels of sulfur remain in the acceptable level. Flue gas is the byproduct of power plants and refers to the exhaust from burning fossil fuels. Flue gas desulfurization is required to reduce the amount of sulfur dioxide getting into the air. It is a large factor in the formation of acid rain.

- 2. Most Common Methods Of Removal Of Sulphur: I.Hydrodesulfurization. II.Chemical Desulphurization. III.Physical Adsorption Of Sulphur Oxide. IIII.Wet Sulfuric acid process. IV. Spray dry scrubbing using similar sorbent slurries.

- 3. I.Hydrodesulfurization: In the hydrodesulfurization process, a mixture of the oil-based raw material and hydrogen gas is heated to 300-400°C and pumped under a pressure of up to 130 atmospheres into a hydrodesulfurization reactor. Here, the mixture passes over a catalyst which breaks the sulfur-carbon bonds, allowing the sulfur to react with the hydrogen to form hydrogen sulfide. There are a number of hydrodesulfurization catalysts, but the one most commonly used consists of molybdenum sulfide, which contains cobalt on an aluminum oxide base. The H2S flows out of the reactor, along with excess hydrogen, and into a treatment unit where it is separated out, allowing the hydrogen to be recycled through the process. Several cycles may be required to reduce the sulfur content to the required level. The hydrogen sulfide produced by HDS is converted to elemental sulfur by a procedure known as the Claus Process — refineries generally have a Claus unit for this purpose. Much of the sulfur recovered in this way is used in the production of sulfuric acid. Although sulfur deposits are still mined, most sulfur production today is from petroleum via the HDS and Claus processes.

- 4. II.Physical Adsorption Of Sulphur Oxide: Macrotyloma uniflorum Lam. is commonly known as horse gram, which belongs to the family Fabaceae. Polyphenols present in seed extract of M. uniflorum were water soluble, heat stable, polar, non-tannin and nonprotein in nature. Taking all these factors into consideration M. uniflorum seed powder was selected as an adsorbent. We tried to examine the possibility of using a well-known physicochemical method as adsorption for the removal of SO2 from aqueous SO2 solution. The initial screening study has been carried by mixing a known amount of M. uniflorum adsorbent into the aqueous solution of SO2 (Angold, 1997). The adsorption experiment is carried out with respect to contact time between aqueous solution and adsorbent, with respect to effect of aqueous SO2 concentration, and with respect to adsorbent dosage.

- 5. III.Chemical Desulphurization: Chemical desulphurization and microwave-chemical desulphurization was employed to remove sulfur in crude oil. Several desulfurizing agents have been selected and investigated. Among these desulfurizing agents, DCP, BPO, BBPV, and BPMC are organic peroxides, while the active oxygen content of organic peroxides is increasing, the oxidation effects become better and the desulfurizing efficiency of crude oil is increasing. BBPV and BPMC are compared with other organic desulfurizing agents, which perform better. Various influencing factors such as dosage of desulfurizer, investigated temperature, and optimum reacting conditions were obtained. The optimized dosage of BBPV, BPMC, and formylhydroperoxide is 1%, 2%, and 15%, respectively. The optimized temperature should be 80–90°C. Microwave inducement can improve the effect of chemical desulphurization and better desulfurizing results were gained. The desulfurizing efficiencies of peroxy acetic acid, BBPV, and BPMC increased from 18.6%, 21.8%, 28.5%, and 24.3% to 34.7%, 33.3%, 34.5%, and 43.3%, respectively. The microwave inducement can decompose sulfone to water-soluble sulfate and sulfite. Thus, organic sulfur was transformed into inorganic sulfur and then removed.