Chapter 5b -_cracking_ffcu

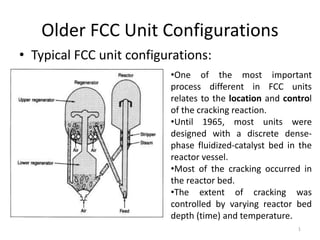

- 1. Older FCC Unit Configurations • Typical FCC unit configurations: •One of the most important process different in FCC units relates to the location and control of the cracking reaction. •Until 1965, most units were designed with a discrete dense- phase fluidized-catalyst bed in the reactor vessel. •Most of the cracking occurred in the reactor bed. •The extent of cracking was controlled by varying reactor bed depth (time) and temperature. 1

- 2. Older FCC Unit Configurations • Although it was recognized that cracking occurred in the rise feeding the reactor because the catalyst activity and temperature were at their highest, no significant attempt was made to regulate the reaction by controlling riser conditions. • After more reactive zeolite catalysts were adopted by refineries, amount of cracking occuring in the rise (transfer line) increased to levels requiring operational changes in existing units. • As a result, most recently constructed units have been designed to operate with a minimum bed level in the reactor and with control of the reaction being maintained by a varying catalyst circulation rate. 2

- 3. Older FCC Unit Configurations • Many older units have been modified to maximize and control riser tracking. • Unit are also operate with different combinations of feed-riser and dense-bed reactors, including: - feed-riser followed by dense-feed - feed riser in parallel with dense-feed - parallel feed-riser lines (one for fresh feed and the other for recycle) 3

- 4. Improvement • Improvements in catalysts and to get more efficient contact of heavy feedstocks with catalysts particles. • The results – higher conversion levels with better selectivity (higher gasoline yields at given conversion levels). • Shorter and better controlled reaction times (1-3 sec) • Improved feed distribution systems 4

- 5. Operations • Fresh feed & recycle streams are preheated by heat exchangers or a furnace and enter the unit at the base of feed riser where they are mixed with the hot regenerated catalyst. • The heat from catalyst vaporizes the feed and brings it up to the desired reaction temperature. • Mixture of catalyst and hydrocarbon vapor travels up the riser into reactors. • Cracking reaction start when the feed contacts the hot catalyst in the riser and continues until the oil vapors are separated from the catalyst in reactor. • The hydrocarbon vapors are sent to synthetic crude fractionator for separation into liquid and gaseous products. 5

- 6. 6

- 7. 7

- 8. New Design of FCC Units • Newer units are designed to incorporate up to 25% reduced crude in FCC unit feed. 1. FLEXICRACKING IIIR design by Exxon Research & Engineering 2. Indmax FCC (I-FCC) Process developed by Indian Oil Corporation (IOCL) 8

- 10. FLEXICRACKING IIIR • FLEXICRACKING IIIR technology includes process design, hardware details, special mechanical and safety features, control systems, flue gas processing options and a full range of technical services and support. • The reactor (1) incorporates many features to enhance performance, reliability and flexibility, including a riser (2) with patented high-efficiency close-coupled riser termination (3), enhanced feed injection system (4) and efficient stripper design (5). • The reactor design and operation maximizes the selectivity of desired products, such as naphtha and propylene. 10

- 11. FLEXICRACKING IIIR • The technology uses an improved catalyst circulation system with advanced control features, including cold- walled slide valves (6). The single vessel regenerator (7) has proprietary process and mechanical features for maximum reliability and efficient air/catalyst distribution and contacting (8). • Either full or partial combustion is used. With increasing residue processing and the need for additional heat balance control, partial burn operation with outboard CO combustion is possible, or KBR dense phase catalyst cooler technology may be applied. 11

- 12. Indmax FCC (I-FCC) Process • This process overcomes the drawbacks or limitations of just adding ZSM-5 (zeolite). • It employs a riser reactor system along with catalyst stripper and catalyst regenerator (just like a conventional FCCU) • Catalyst formulation is unique & very different from what has been used before, it specific to each operation and depends on feedstock characteristics. 12

- 13. Indmax FCC (I-FCC) Process • The process utilises a higher riser reactor temp. (530 – 600 degree C), a higher catalyst to oil ratio (12-20) and lower hydrocarbon partial pressure to achieve high conversion and selectivity. • Lummus Technology: Micro jet feed injectors, riser design, reaction termination device (RTD), modular grid catalyst stripper. • I-FCC process’s catalyst formulation, hardware design and operating strategy can upgrade heavy feeds for high yield of light olefins. 13

- 14. FCC Regenerator • FCC regenerator is a key part of an FCC unit to recover solid catalyst activity by burning off the coke deposit on the catalyst surface • The spent catalyst (that leave the reactor) and contains hydrocarbon adsorbed on its internal and external surfaces as well as the coke deposited by the cracking. • Adsorbed hydrocarbon removed by stripping before the catalyst enters the regenerator. 14

- 15. 56 – Fluidized catalyst bed 82 – Dip leg 80 – 2 stage cyclones Flue gas to CO Boiler Regeneration air from blower Regenerated catalyst to reactor-riser Air grid Plenum Chamber *CO boiler (Steam generating boiler) Spent catalyst from reactor Typical FCC Regenerator diagram 15

- 16. FCC Regenerator • In regenerator, coke is burned from the catalyst with air. • Regenerator temperature and coke burn-off are controlled by varying the air flow rate. • Heat of combustion raises the catalyst temp. to 620 – 845 degree C. • Regenerated catalyst contains from 0.01 to 0.4 wt% residual coke. 16

- 17. FCC Regenerator – Old vs New • Older units - designed to burn CO to minimize blower capital and operating cost – because only about half as much air had to be compressed to burn to carbon monoxide rather than to CO2. • Newer units - designed and operated to burn the coke to CO2 in the regenerator because they can burn to a much lower residual carbon level on the generated catalyst. - Gives more reactive & selective catalyst in the riser and a better product distribution results at the same equilibrium catalyst activity and conversion level. 17

- 18. FCC Regenerator – CFD Model • The next video shows the model of a full-scale fluidized catalytic cracking (FCC) regenerator using the Eulerian- Lagrangian CPFD (computational particle fluid dynamics) method. • This is a simulation of an actual operating unit in at a U.S. refinery. • This is the first simulation of its kind known to exist for an entire FCC regenerator with the coke-burning chemistry included. T • he purpose of the simulation was to determine root causes for afterburn in the unit (undesirable temperature rise between the top of the bed and the discharge), which has been present in unit for over 70 year and has never before successfully been addressed. 18

- 19. FCC Regenerator – CFD Model • http://www.youtube.com/watch?v=RHrrNRC3rjo 19

- 20. Process variables • Major operating variables effecting the conversion and product distribution: Activity : ability to crack a gas oil to lower boiling fractions catalyst/oil ratio (C/O) = lb catalyst/lb feed conversion = 100 (volume of feed – volume of cycle stock)/ volume of feed Efficiency = (% gasoline) x conversion 20

- 21. Process variables -recycle ratio = volume recycle/ volume fresh feed Selectivity : the ratio of the yield of desirable products to the yield of undesirable products (coke and gas) Cycle stock: portion of catalytic-cracker effluent not converted to naphtha and lighter products 21

- 22. Operating Conditions & Design Features • Designed to provide balance of reactor and regenerator capabilities. • Usually operate to one or more mechanical limits, common limit is capacity to burn carbon from the catalyst if air compressor capacity is limit, capacity may be increased at feasible capital cost. If regenerator metallurgy is limit, design changes can be formidable. Regenerator cyclone velocity limit Slide valve ∆P limit 22

- 23. Product Yields • Produces high yields of liquids and small amounts of gas and coke -mass liquid yields are usually 90% - 93%; liquid volume yields are often more than 100% • The yield pattern is determined by complex interaction of feed characteristics and reactor conditions that determine severity of operation. • Conversion defined relative to what remains in the original feedstock boiling range • Conversion = 100% - (gas oil yield) 23

- 24. Health and Safety Considerations -Fire Prevention and Protection Liquid hydrocarbons in the catalyst or entering the heated combustion air stream should be controlled to avoid exothermic reactions. Because of the presence of heaters in catalytic cracking units, the possibility exists for fire due to a leak or vapor release. Fire protection including concrete or other insulation on columns and supports, or fixed water spray or fog systems where insulation is not feasible and in areas where firewater hose streams cannot reach, should be considered. In some processes, caution must be taken to prevent explosive concentrations of catalyst dust during recharge or disposal. When unloading any coked catalyst, the possibility exists for iron sulfide fires. Iron sulfide will ignite spontaneously when exposed to air and therefore must be wetted with water to prevent it from igniting vapors. 24

- 25. Regular sampling and testing of the feedstock, product, and recycle streams should be performed to assure that the cracking process is working as intended and that no contaminants have entered the process stream. Corrosives or deposits in the feedstock can foul gas compressors. Inspections of critical equipment including pumps, compressors, furnaces, and heat exchangers should be conducted as needed. When processing sour crude, corrosion may be expected where temperatures are below 900° F. Corrosion takes place where both liquid and vapor phases exist, and at areas subject to local cooling such as nozzles and platform supports. When processing high-nitrogen feedstock, exposure to ammonia and cyanide may occur, subjecting carbon steel equipment in the FCC overhead system to corrosion, cracking, or hydrogen blistering. Inspections should include checking for leaks due to erosion or other malfunctions such as catalyst buildup on the expanders, coking in the overhead feeder lines from feedstock residues, and other unusual operating conditions. Health and Safety Considerations -Safety 25

- 26. Because the catalytic cracker is a closed system, there is normally little opportunity for exposure to hazardous substances during normal operations. The possibility exists of exposure to extremely hot (700° F) hydrocarbon liquids or vapors during process sampling or if a leak or release occurs. In addition, exposure to hydrogen sulfide and/or carbon monoxide gas may occur during a release of product or vapor. Catalyst regeneration involves steam stripping and decoking, and produces fluid waste streams that may contain varying amounts of hydrocarbon, phenol, ammonia, hydrogen sulfide, mercaptan, and other materials depending upon the feedstock, crudes, and processes. Safe work practices and/or the use of appropriate personal protective equipment may be needed for exposures to chemicals and other hazards such as noise and heat; during process sampling, inspection, maintenance and turnaround activities; and when handling spent catalyst, recharging catalyst, or if leaks or releases occur. Health and Safety Considerations -Health 26