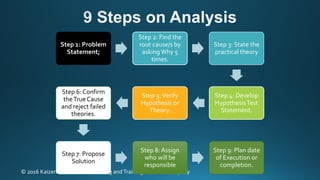

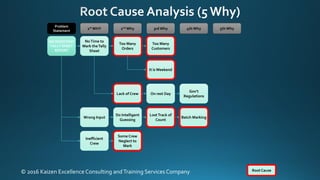

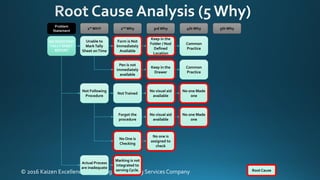

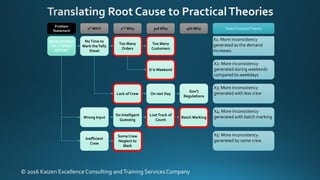

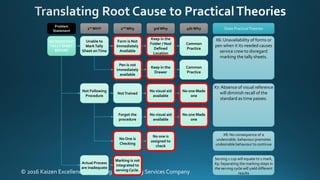

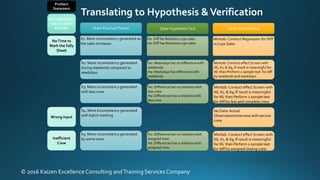

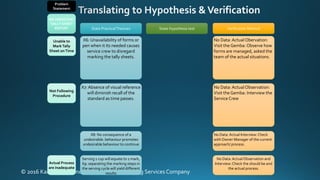

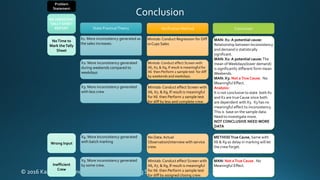

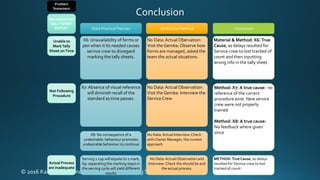

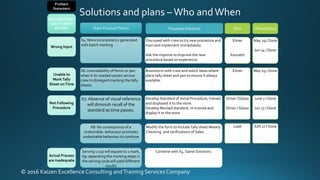

Kaizen Excellence Consulting offers consulting and training services to support operational excellence through continuous improvement and lean initiatives. The document outlines a structured problem-solving approach, emphasizing root cause analysis using the '5 Whys', developing hypotheses, and proposing solutions related to inconsistent tally sheet reports and other operational inefficiencies. Various methods and tools, including statistical analysis via Minitab, are suggested for verification of hypotheses and testing of proposed solutions.