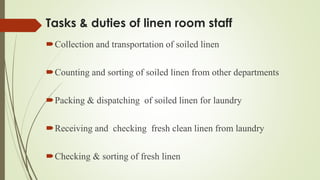

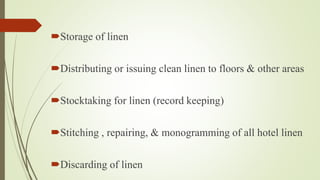

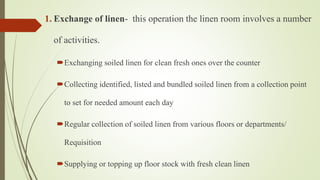

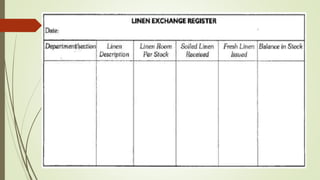

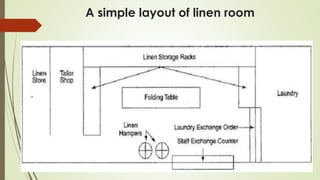

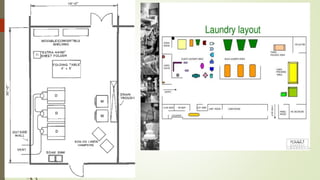

The document outlines the operations and management of linen rooms in hospitality settings, detailing the roles and responsibilities of linen room staff, types of linen rooms (centralized and decentralized), and tasks such as sorting, storing, and inspecting linen. It emphasizes the importance of proper linen control methods and inventory management to maintain hygiene and efficiency. The document also highlights that linen rooms can be found in various establishments beyond hotels, including hospitals and colleges.