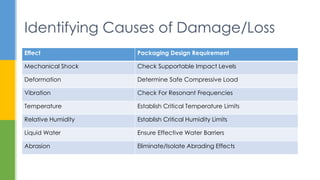

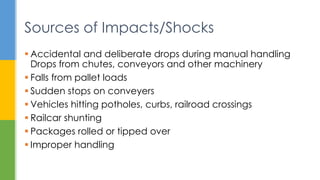

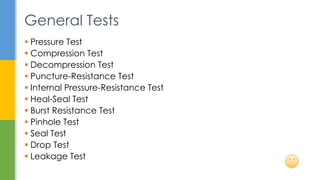

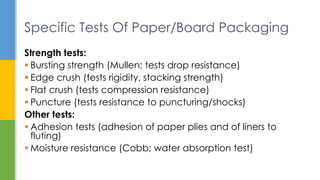

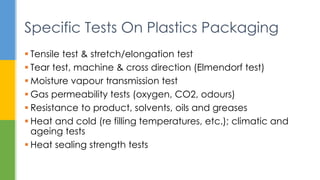

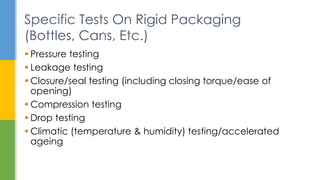

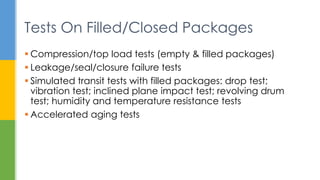

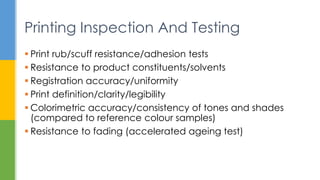

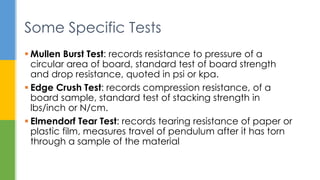

The document discusses packaging material testing and quality assurance. It outlines various tests that should be conducted on packaging materials and filled packages to evaluate their performance in distribution environments and ensure they can withstand hazards like mechanical shocks, vibrations, compression, temperatures, and humidity levels. These tests include burst resistance tests, compression tests, drop tests, puncture resistance tests, seal tests, and climatic testing. Specific tests are described for different packaging materials like paper, plastic, rigid containers, and printed packaging.