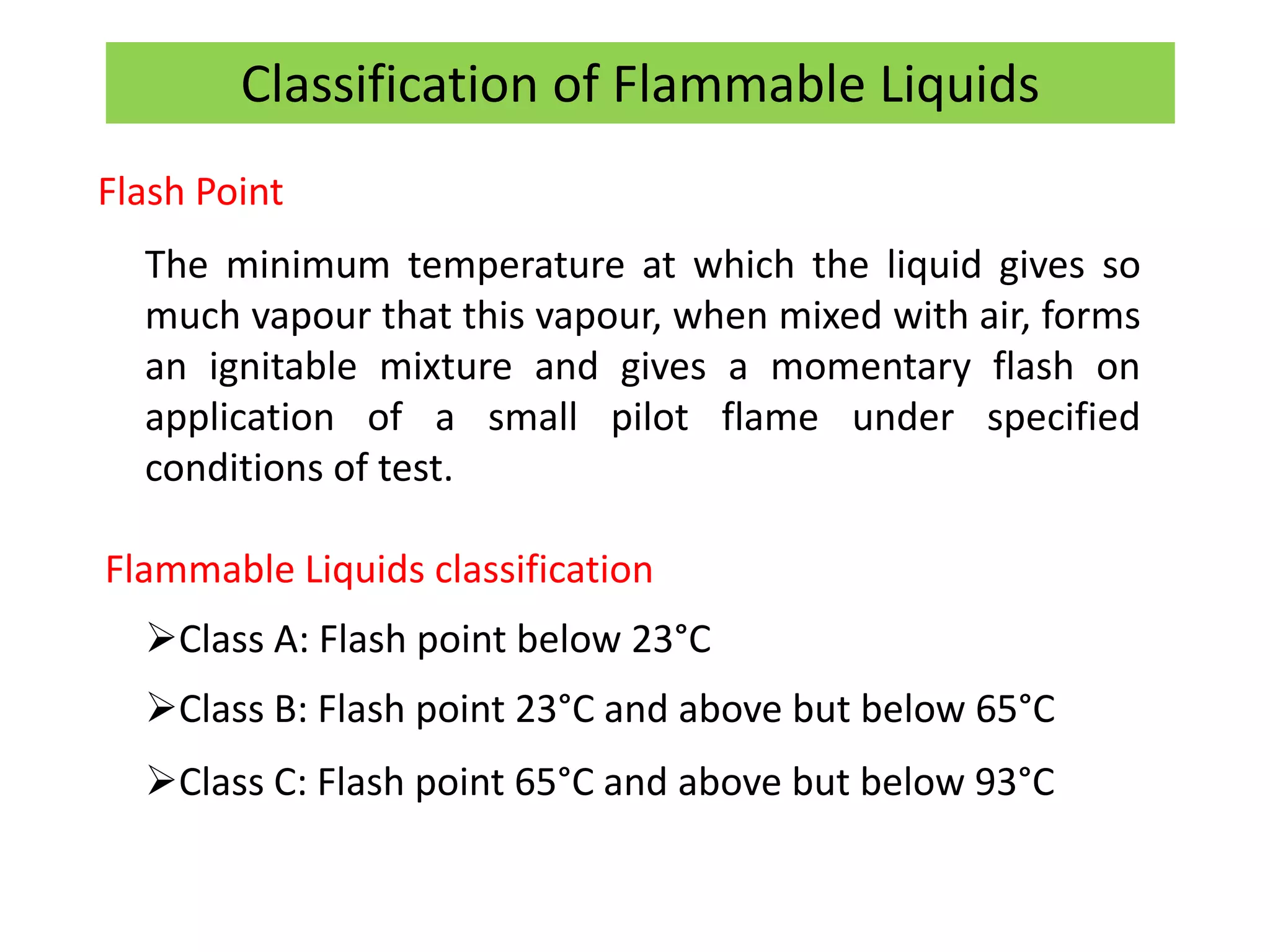

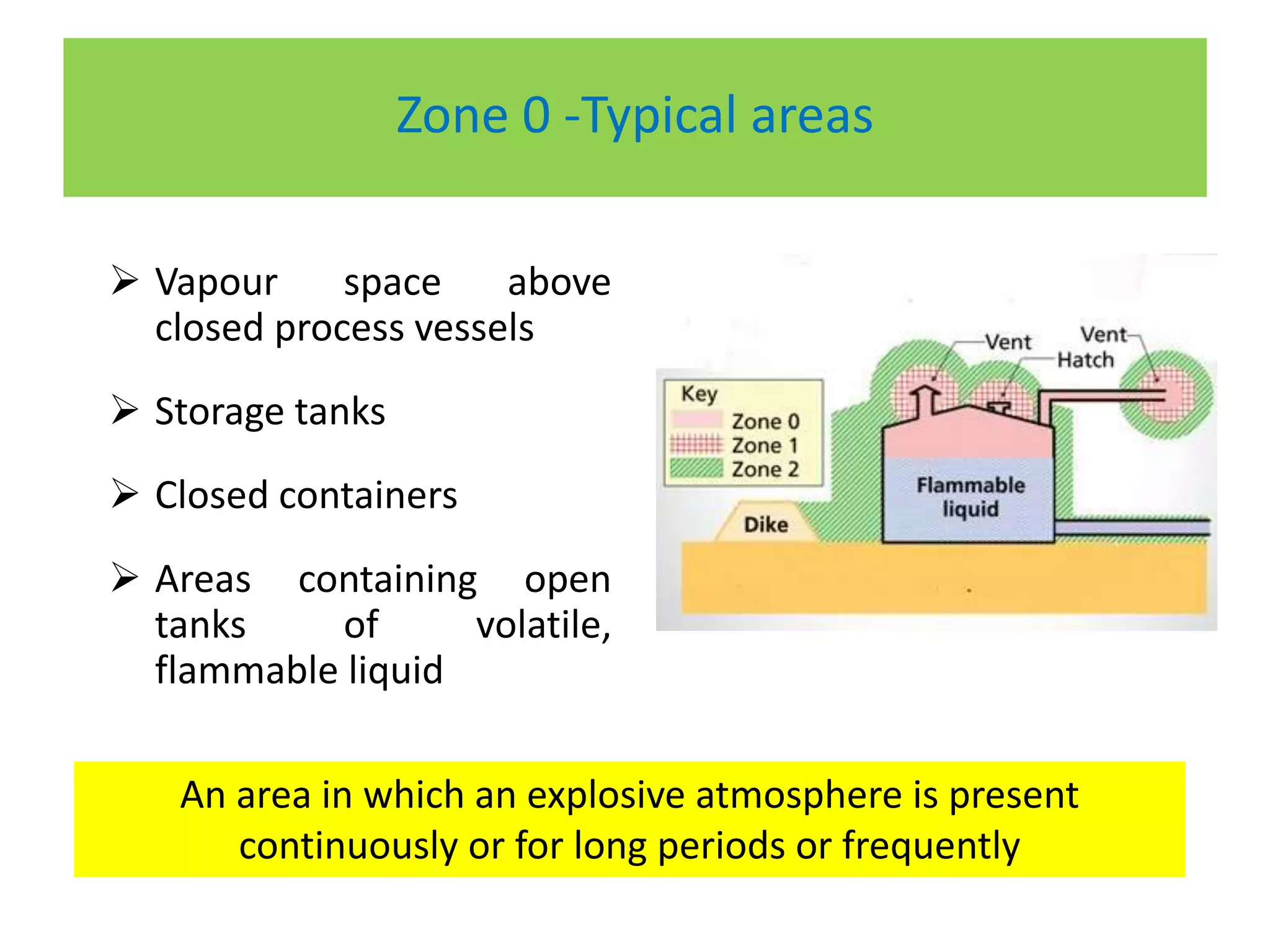

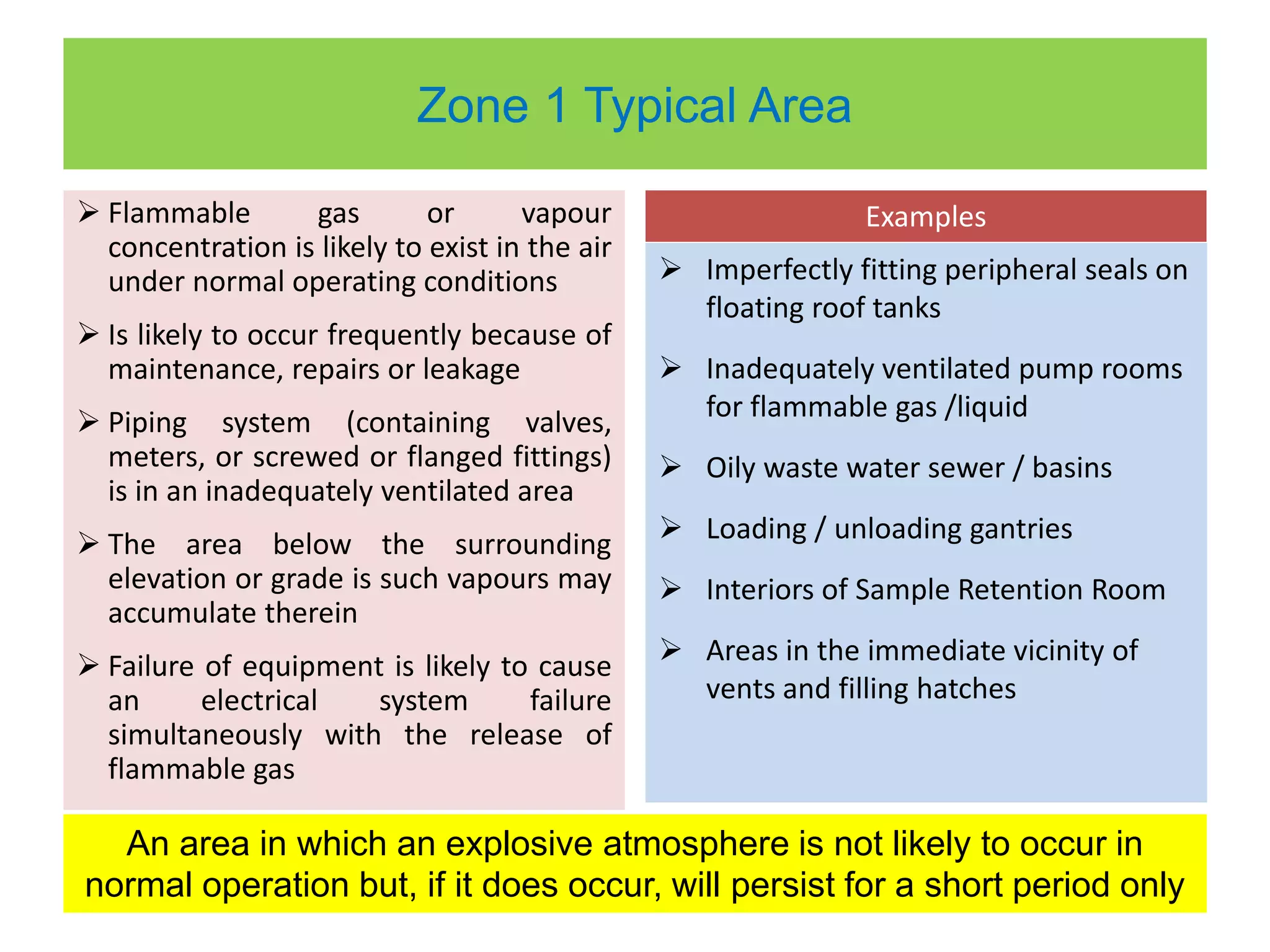

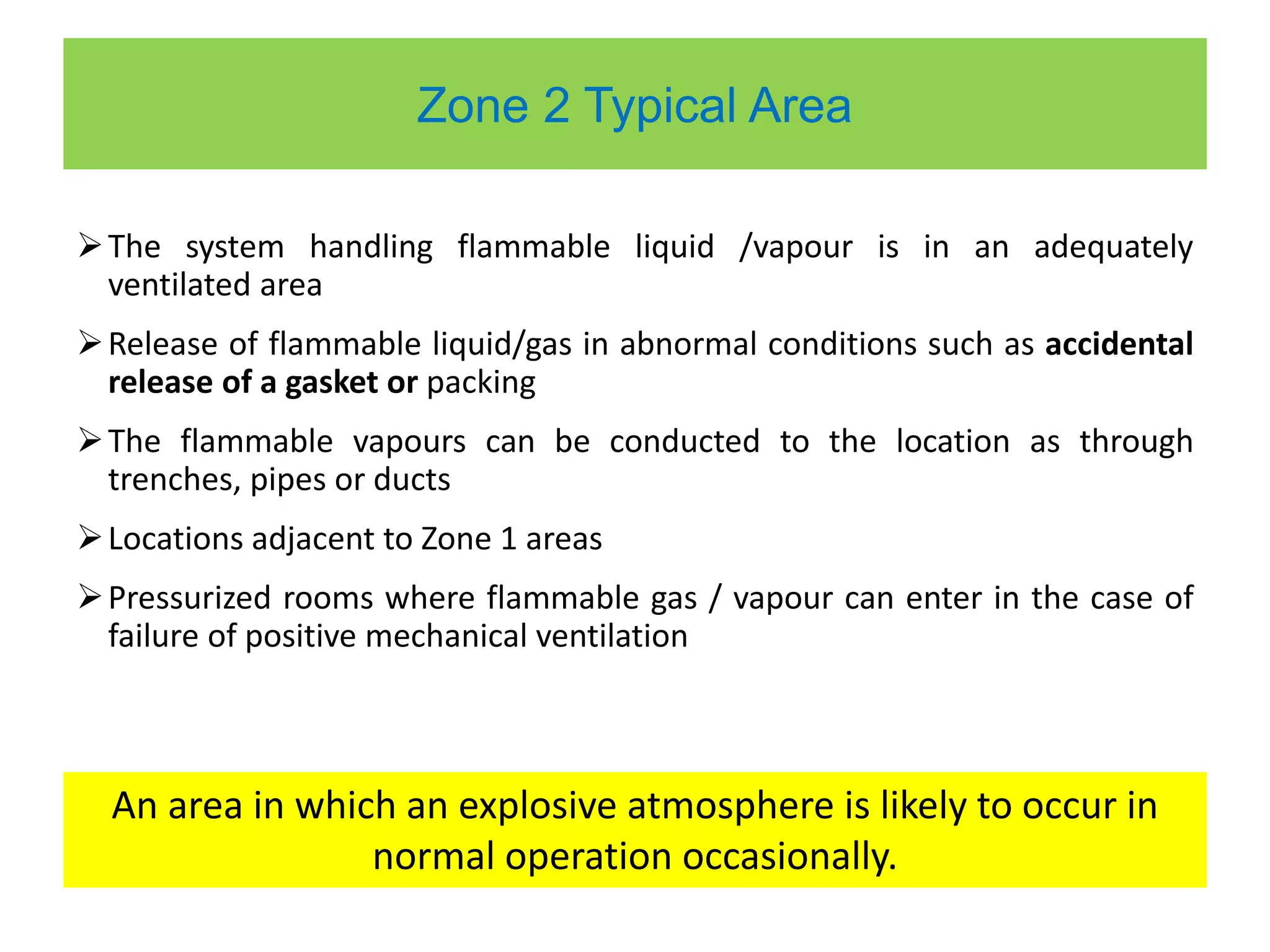

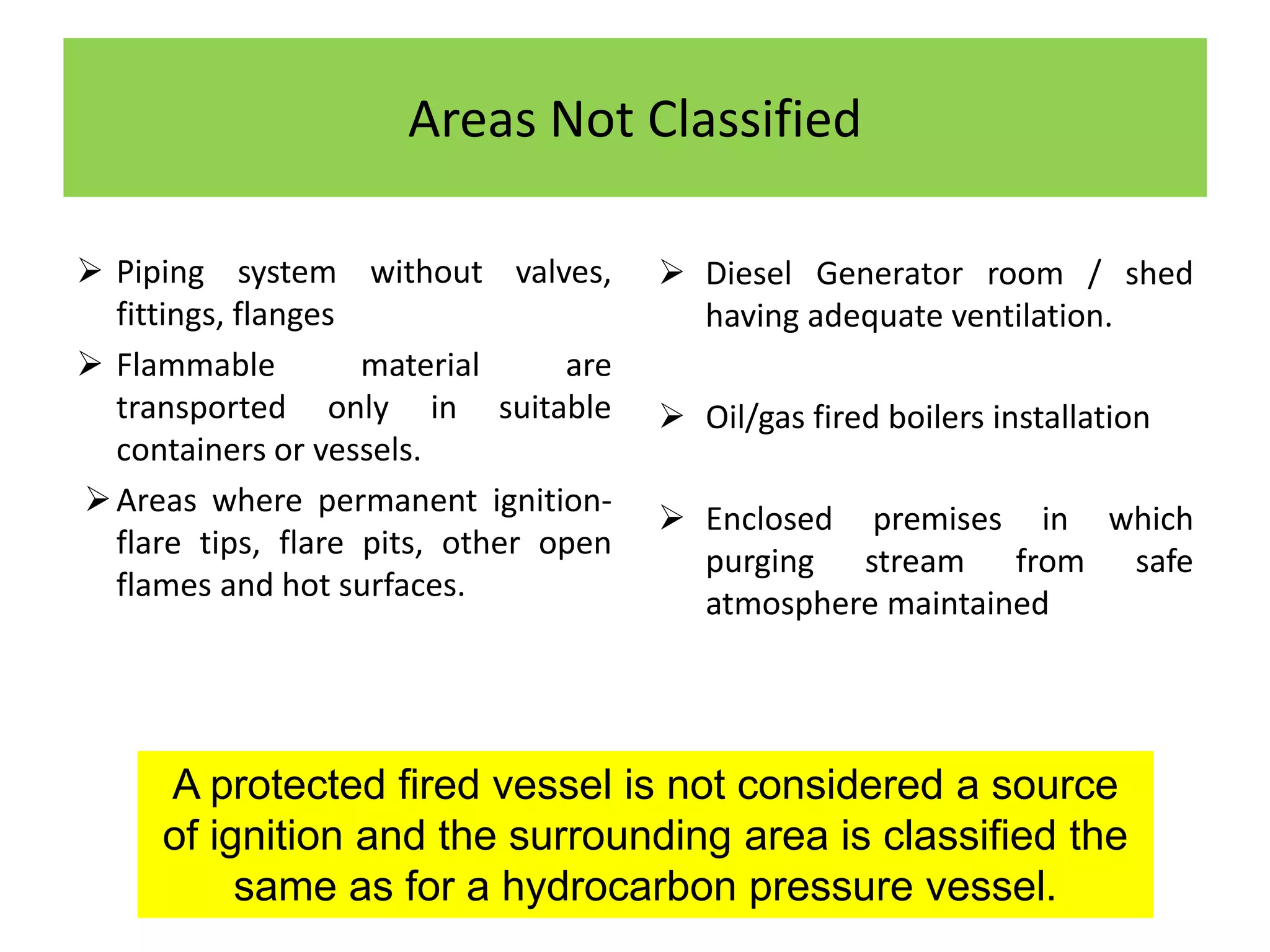

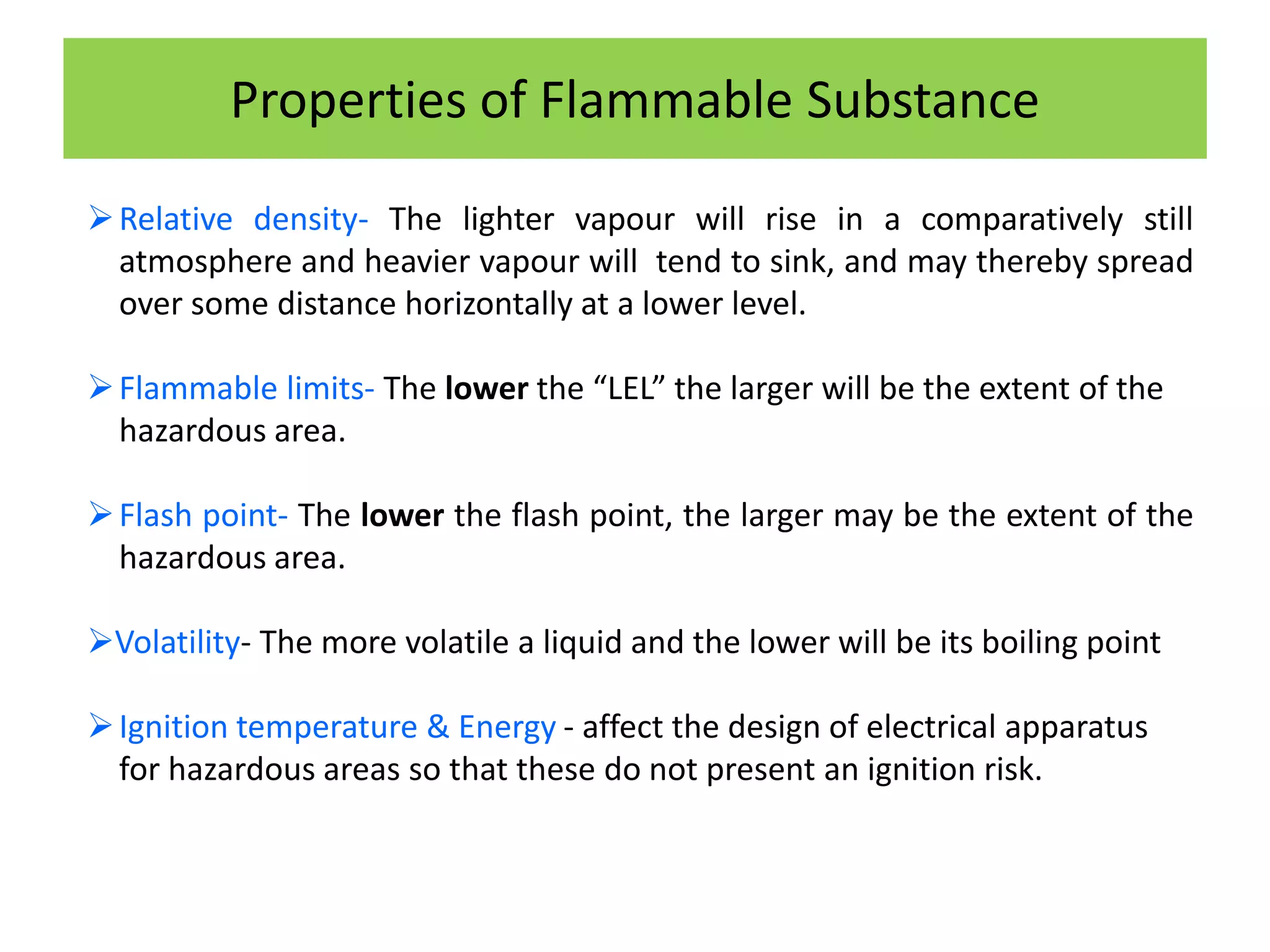

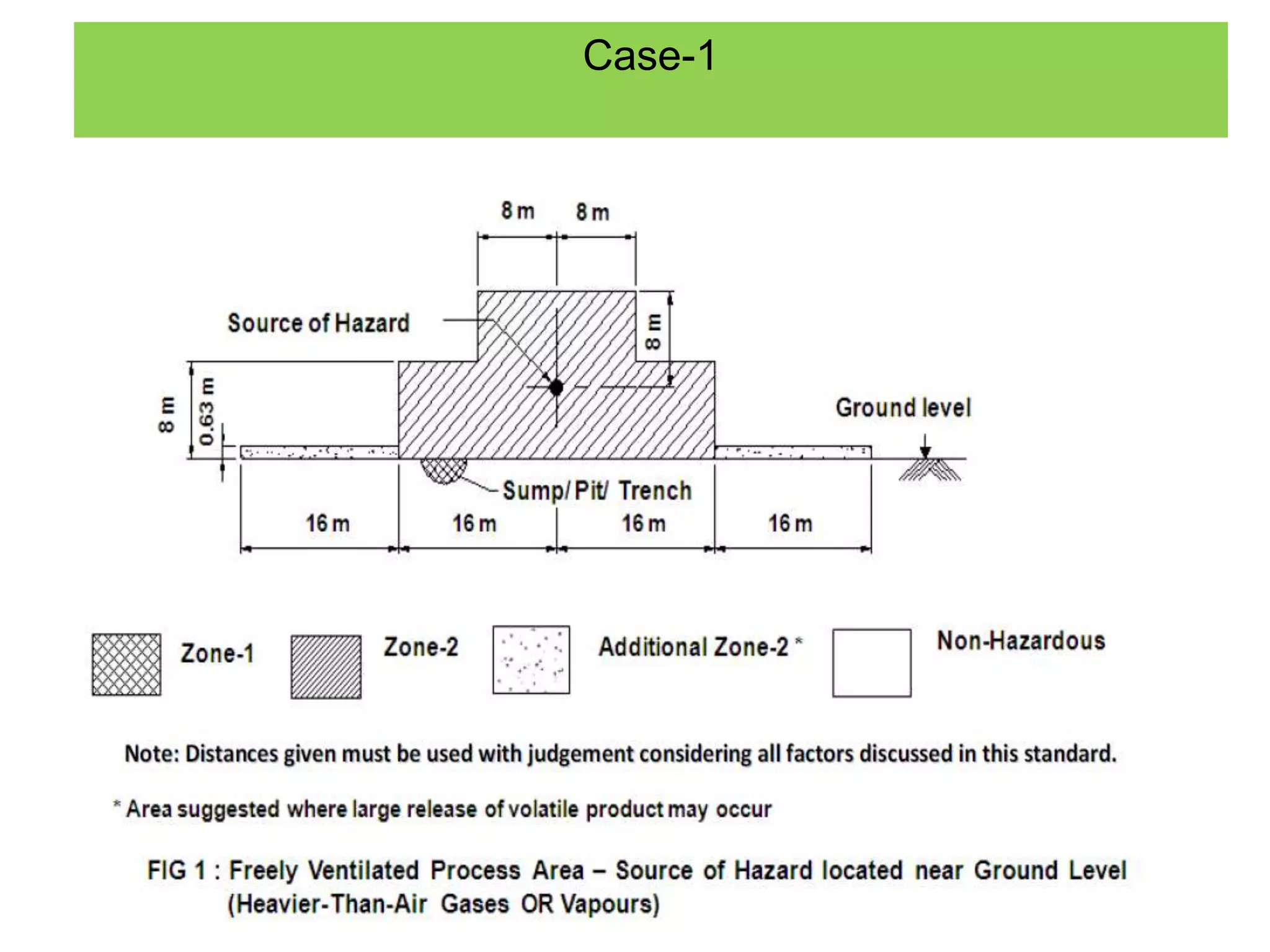

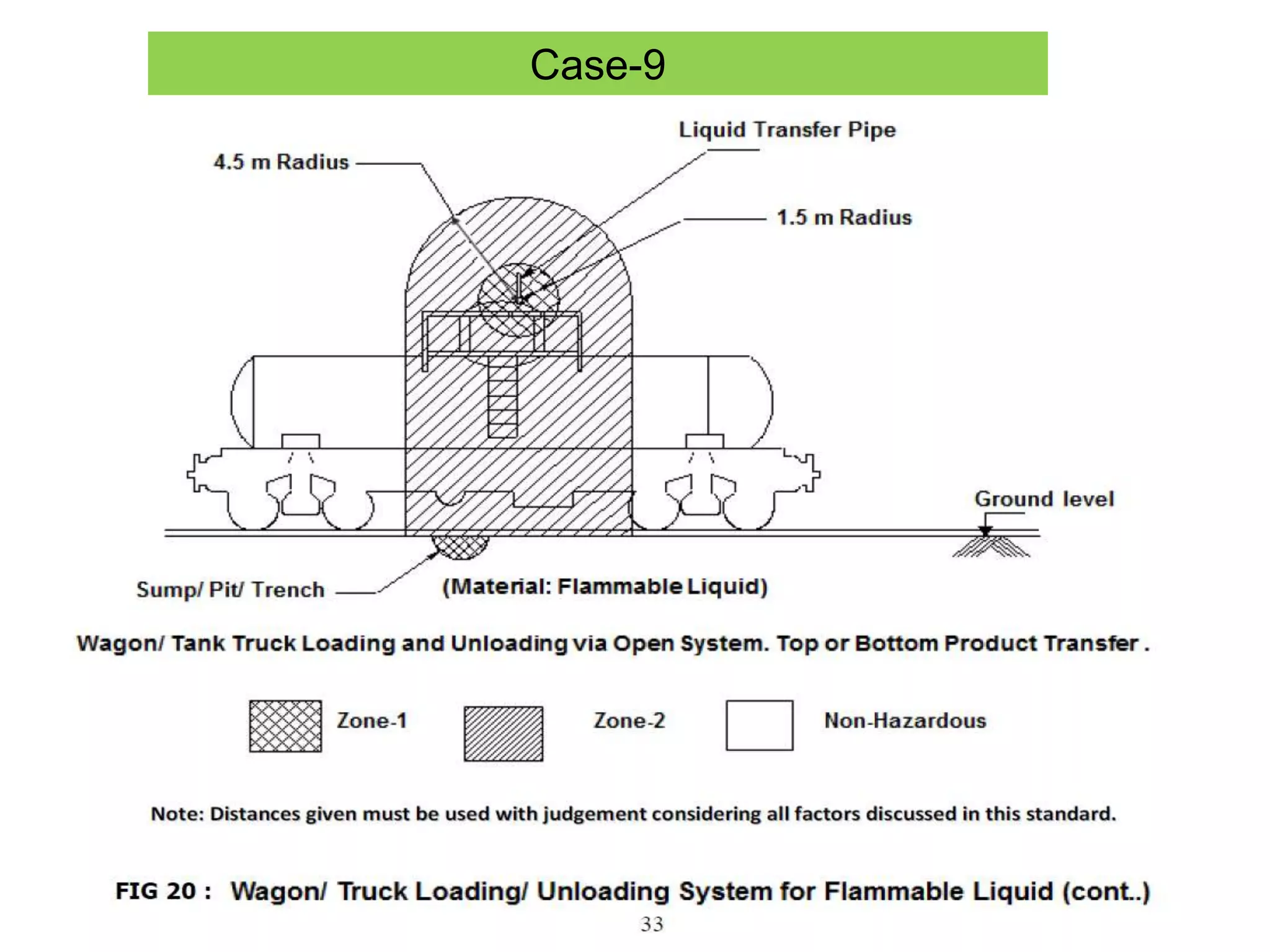

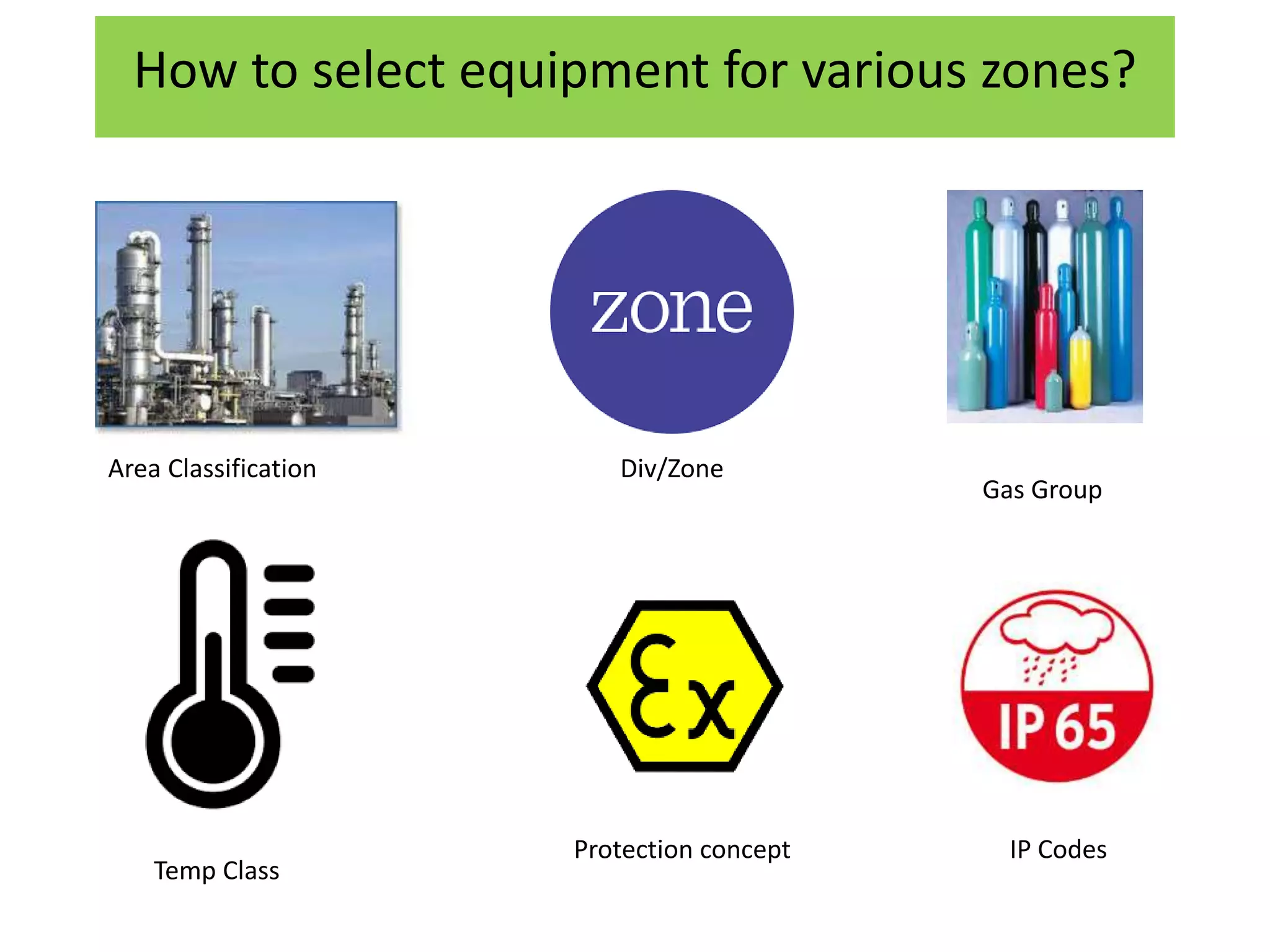

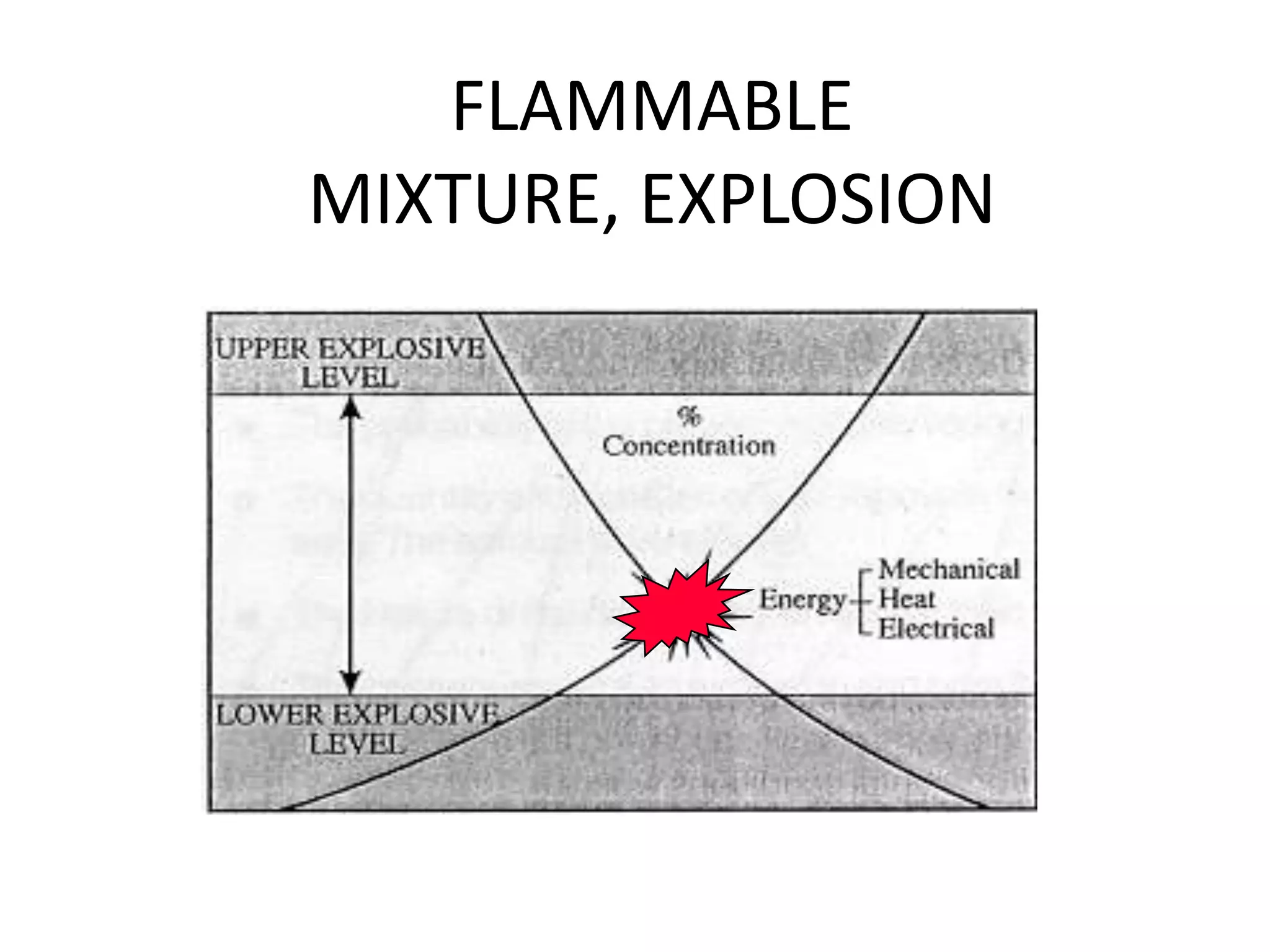

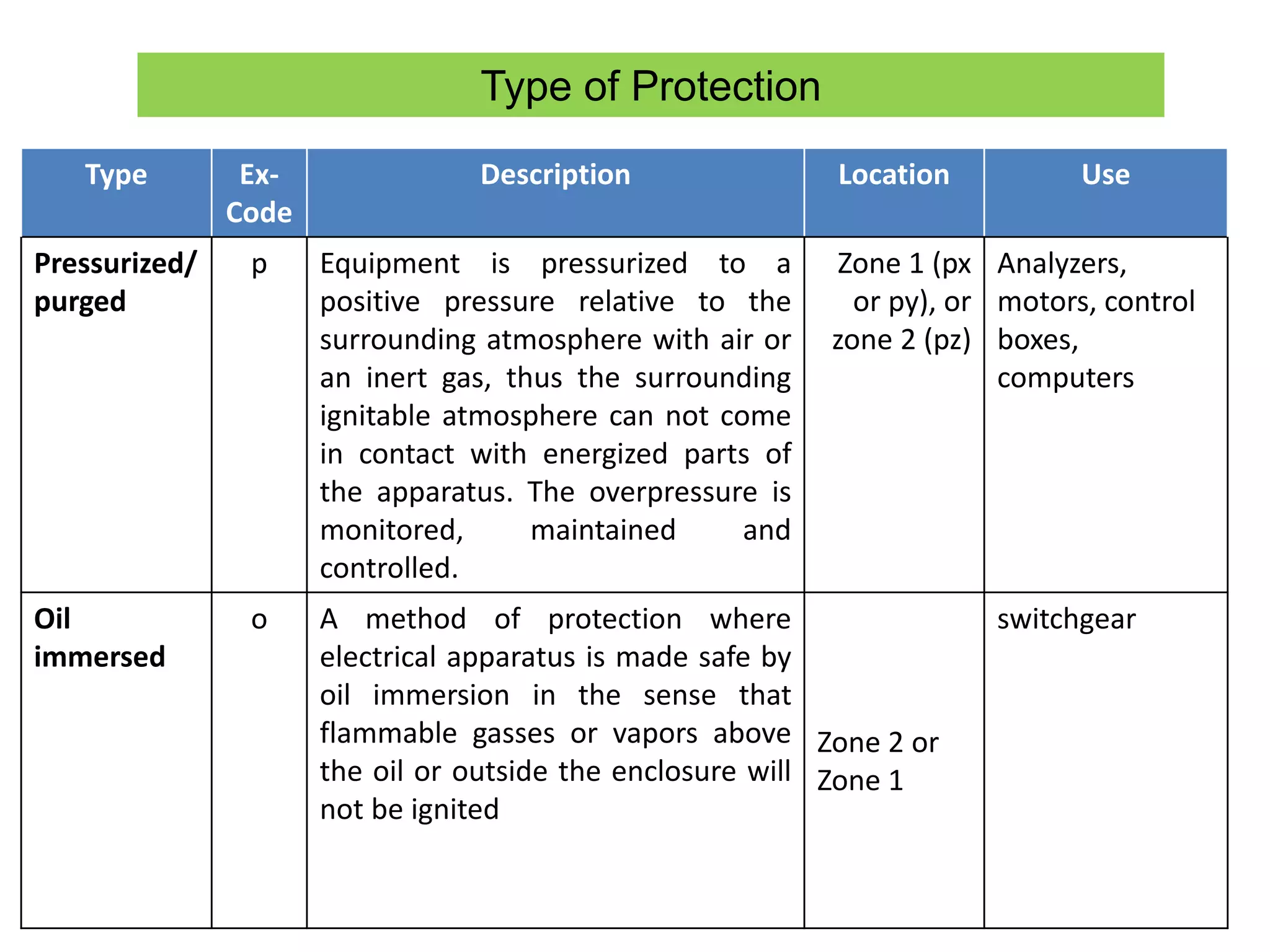

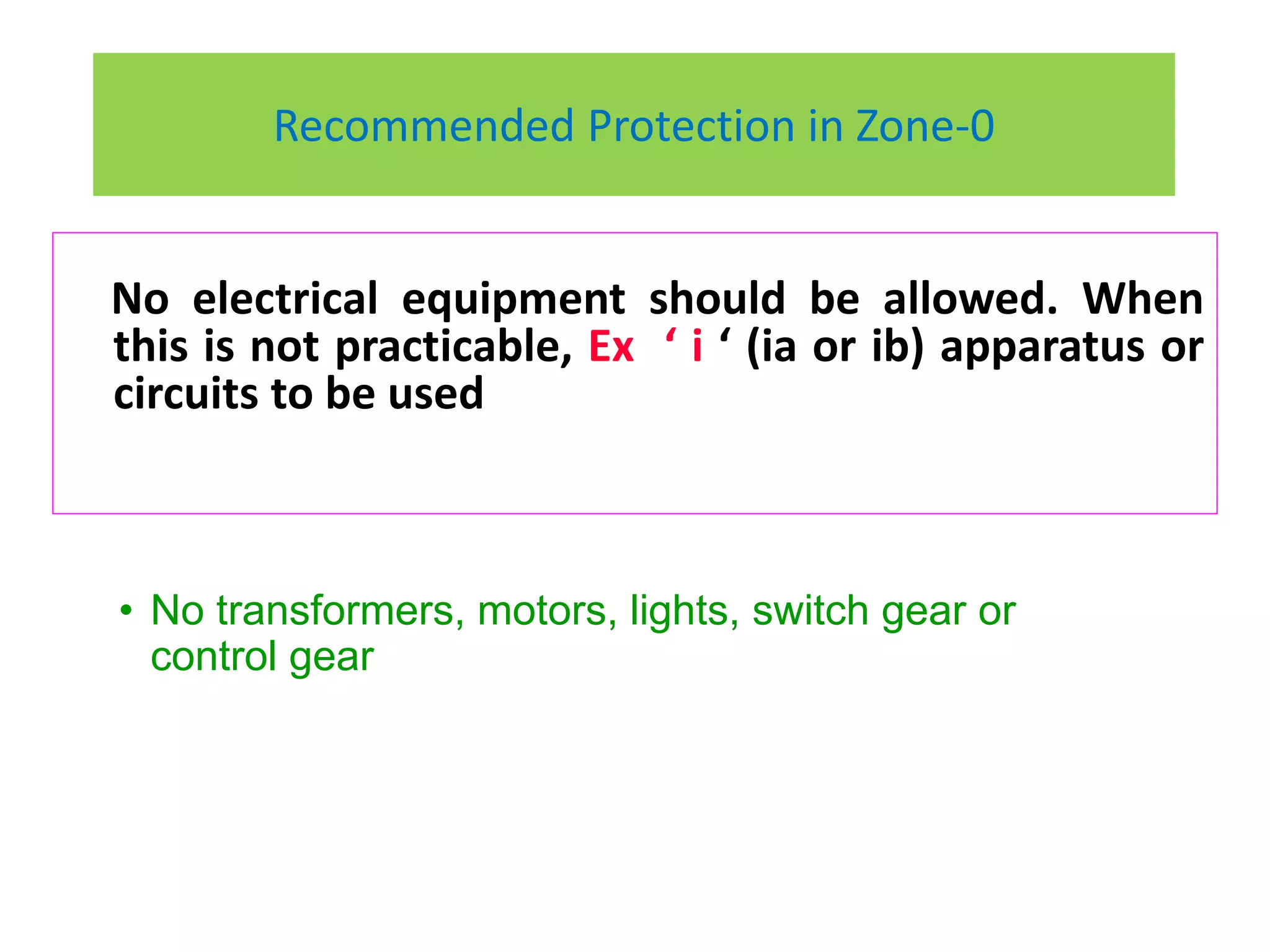

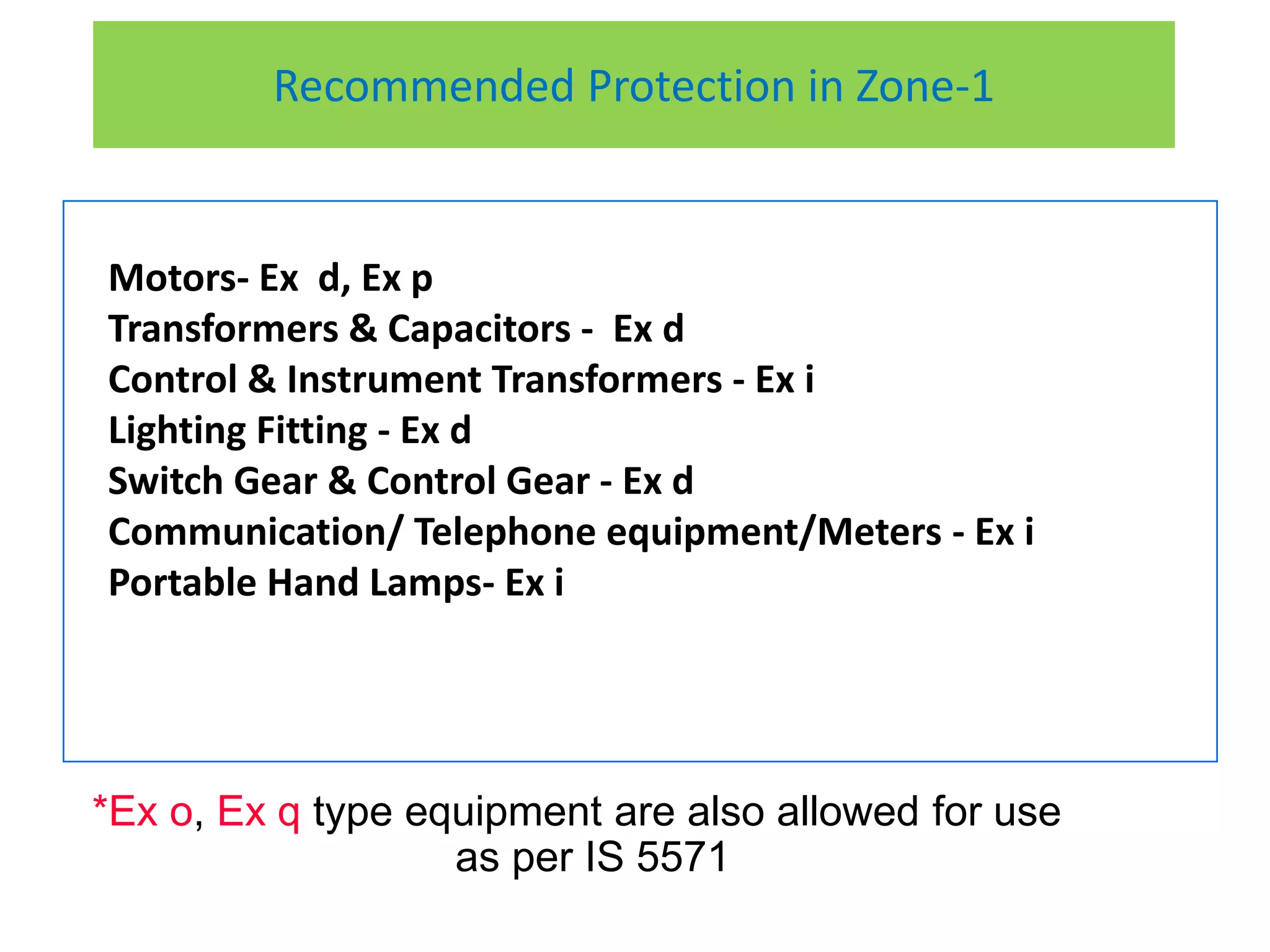

This document discusses hazardous area classification. It defines hazardous areas as areas where flammable gases or vapors may be present. Areas are classified into zones based on the likelihood and duration of an explosive atmosphere occurring. Zone 0 areas have explosive atmospheres present continuously, Zone 1 areas have them likely to occur occasionally, and Zone 2 areas are not likely but possible for short periods. Selection of electrical equipment depends on the area classification and gas properties. Standards provide guidelines for equipment certification to ensure safe operation in hazardous environments.