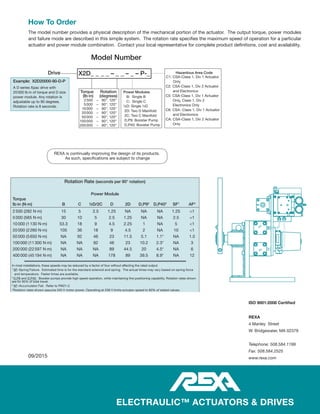

The Rexa XPAC series 2 X2D features a self-contained electraulic power module that enables precise actuator positioning independent of load variations, using a patented flow match system to generate hydraulic flow. The system accommodates various sizes and configurations to optimize speed and torque for different applications, while providing low maintenance and robust performance. Key functionalities include microprocessor control for flexibility, user-configurable settings, and advanced communication protocols for integration into process control systems.