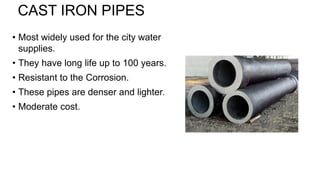

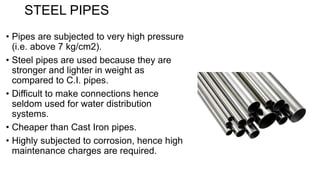

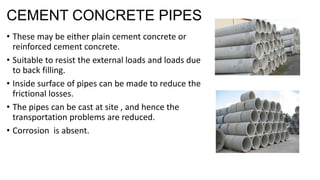

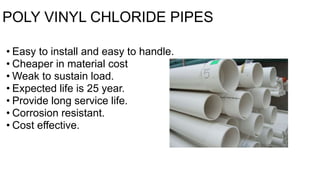

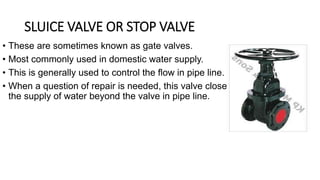

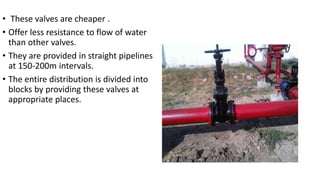

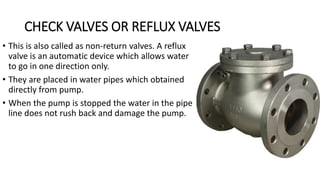

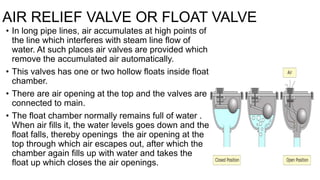

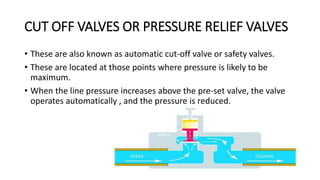

This document discusses different types of pipes and valves used in water supply systems. It describes common pipe materials like cast iron, steel, concrete, plastic and their properties. It also explains different valves - stop valves control water flow, check valves allow one-way flow, air relief valves remove trapped air, drain valves empty lines, and pressure relief valves release excess pressure. Pipes and valves are essential to control and distribute water while minimizing losses.