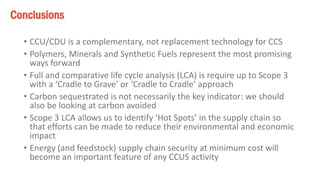

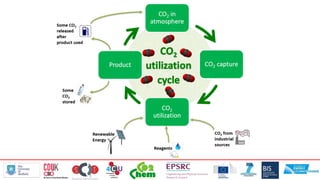

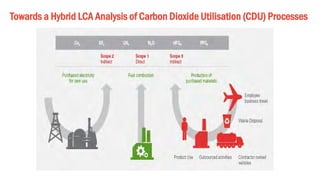

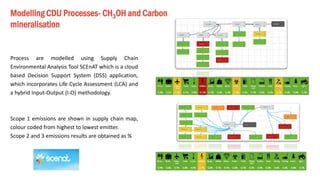

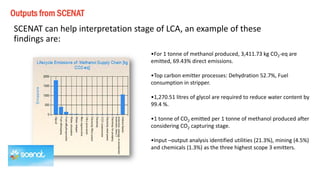

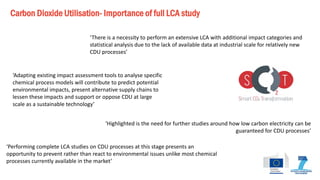

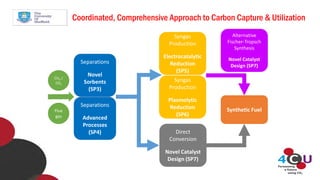

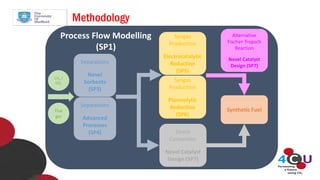

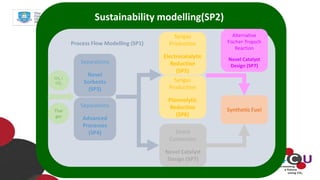

Professor Peter Styring discusses the potential benefits of carbon dioxide utilization (CCU) and the importance of comprehensive life cycle assessments (LCA) for carbon dioxide utilization processes. The document emphasizes the need for detailed studies to analyze environmental impacts, while highlighting major sources of CO2 emissions from methanol production and the necessity for low carbon electricity in CCU. It concludes that CCU can complement, rather than replace, carbon capture and storage (CCS) and identifies polymers, minerals, and synthetic fuels as promising areas for further development.

![1.01 kg CO2 sequestered /1.00 kg polymer

Poly(methyl acrylate)

[PMA]

Polymers](https://image.slidesharecdn.com/peterstyringcardiffbasep14-140918090645-phpapp01/85/How-Can-CCU-Provide-a-Net-Benefit-presentation-by-Peter-Styring-at-the-UKCCSRC-Cardiff-Biannual-Meeting-10-11-September-2014-11-320.jpg)