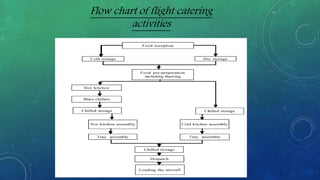

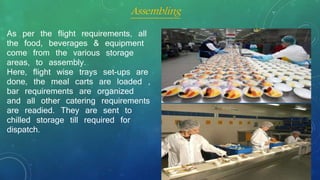

The document discusses flight catering processes which include ordering raw materials, food preparation in hot and cold kitchens, quality control checks, assembly of meals according to flight requirements, storage and dispatch to planes. It also covers health and safety standards that are important in flight catering like avoiding certain raw foods, food handler hygiene practices, and food testing. The document defines convenience foods as commercially prepared foods that require minimal preparation and are portable or shelf-stable.