Final poster

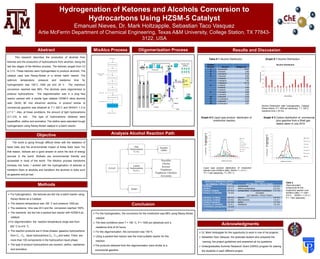

- 1. This research describes the production of alcohols from ketones and the production of hydrocarbons from alcohols, being the last two stages of the MixAlco process. The ketones ranged from C3 to C13. These ketones were hydrogenated to produce alcohols. The catalyst used was Raney-Nickel in a stirred batch reactor. The optimum temperature, pressure and residence time for hydrogenation was 150˚C 1000 psi and 24 h. The maximum conversion reached was 98%. The alcohols were oligomerized to produce hydrocarbons. The oligomerization was in a plug flow reactor packed with a zeolite type catalyst HZSM-5 silica alumina ratio (Si/Al) 80 mol silica/mol alumina. A product similar to commercial gasoline was obtained at T = 320˚C and WHSV= 1.3 to 2.7 h–1. Also, at these conditions, the amount of light hydrocarbons (C1–C4) is low. The type of hydrocarbons obtained were isoparaffins, olefins and aromatics. The olefins were saturated trough hydrogenation using Raney-Nickel catalyst in a batch reactor. Dr. Mark Holtzapple for the opportunity to work in one of his projects. Sebastian Taco Vasquez, the graduate student who prepared the training, the project guidelines and answered all my questions. Undergraduates Summer Research Grant (USRG) program for placing the students in each different project. The world is going through difficult times with the depletion of fossil fuels and the environmental impact of these fuels have. For that reason, biofuels are a good answer to solve the lack of energy sources in the world. Biofuels are environmental friendly and accessible in most of the world. The MixAlco process transforms biomass into fuels. I worked with the hydrogenation of ketones to transform them to alcohols and transform the alcohols to fuels such as gasoline and jet fuel. Abstract Objective Methods Conclusion Acknowledgments Hydrogenation of Ketones and Alcohols Conversion to Hydrocarbons Using HZSM-5 Catalyst Emanuel Nieves, Dr. Mark Holtzapple, Sebastian Taco Vasquez Artie McFerrin Department of Chemical Engineering, Texas A&M University, College Station, TX 77843- 3122, USA For the hydrogenation, the conversion for the mixAlcohol was 98% using Raney-Nickel catalyst. The best conditions were T = 150 ˚C, P = 1000 psi (absolute) and a residence time of 24 hours. For the oligomerization, the conversion was 100 %. Using a packed bed reactor was the most suitable reactor for this reaction. The products obtained from the oligomerization were similar to a commercial gasoline. Results and Discussion Alcohol Distribution after hydrogenation. Catalyst Raney Nickel, P = 1000 psi (absolute), T = 150˚C, residence time = 24 hrs. Graph # 2 Liquid type product distribution of mixAlcohol reaction. Graph # 3 Carbon distribution of commercial plus gasoline from a Shell gas station taken in July 2010. Liquid type product distribution of mixalcohol reaction over HZSM-5 (280), WHSV = 1.31 h–1, P = 1 atm (absolute), T = 370 ˚C . Analysis Alcohol Reaction Path For hydrogenation, the ketones are fed into a batch reactor using Raney Nickel as a Catalyst. The reaction temperature was 150 ˚C and pressure 1000 psi. The residence time was 24 h and the conversion reached 100%. The reactants are fed into a packed bed reactor with HZSM-5 as catalyst. For oligomerization, the reaction temperature range was from 300 ˚C to 410 ˚C. The reaction products are in three phases: gaseous hydrocarbons from C1 - C4 , liquid hydrocarbons C5 - C13 and water. There are more than 100 components in the hydrocarbon liquid phase. The type of product hydrocarbons are isomers, olefins, naphtenes and aromatics. MixAlco Process Oligomerization Process Table # 1 Alcohol Distribution Graph # 1 Alcohol Distribution Carbon Number Alcohol Weight (%) 3 isopropanol 13.47 4 2-butanol 2.66 5 2-pentanol 9.15 6 3-hexanol 0.88 2-hexanol 2.72 7 4-heptanol 1.60 2-heptanol 19.15 8 4-octanol 1.17 3-octanol 2.46 2-octanol 4.28 9 4-nonanol 9.58 2-nonanol 3.46 10 5-decanol 5.23 11 6-undecanol 14.05 12 6-decanol 4.67 13 6-tridecanol 2.91 0.00 5.00 10.00 15.00 20.00 25.00 isopropanol 2-butanol 2-pentanol 3-hexanol 2-hexanol 4-heptanol 2-heptanol 4-octanol 3-octanol 2-octanol 4-nonanol 2-nonanol 5-decanol 6-undecanol 6-decanol 6-tridecanol 3 4 5 6 7 8 9 10 11 12 13 Concentration(wt%) Carbon Number Alcohol Distribution Olefins and Naphtenes Olefinics (g C Species i /100 g C liquid ) Naphtenes (g C Species i /100 g C liquid ) 1-propene 1.4–1.5 cyclohexane 1.0–2.3 2-butene 3.3–7.7 methyl-cyclopentane 2.3–2.9 2-methyl-1-butene 4.7–5.3 cyclopentane, 1,2-dimethyl-3-methylene 1.7–1.9 2-butene, 2,3-dimethy 1.6–6.6 Aromatics (g C Species i /100 g C liquid ) 2-pentene, 2-methyl 2.6–4.2 toluene 1.6–3.4 2-pentene, 3-methyl 2.4–8.5 ethyl benzene 1.3–2.1 3-methyl-2-pentene 2.0–5.8 xylene 1.7–7.8 2-hexene, 2,3-dimethyl 1.9–5.1 mesitylene 1.8–2.6 1,5-dimethyl-cyclopentene 1.3–2.8 1,3-dimethyl-cyclohexene 2.0–3.7 Table 2 Most abundant compounds for the mixalcohol reaction over HZSM-5 (280), T = 300– 415˚C, WHSV = 1.31 h–1, P = 1 atm (absolute).