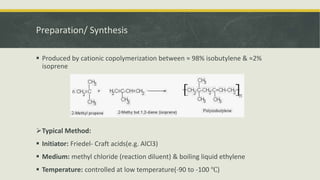

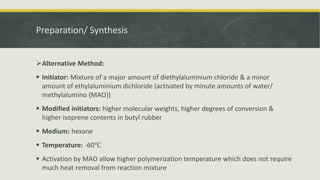

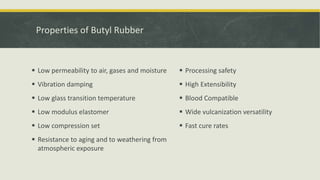

Butyl rubber is synthesized mainly through cationic copolymerization of isobutylene and isoprene, with specific initiators and controlled low temperatures for optimal production. It exhibits excellent properties such as low permeability, vibration damping, and weather resistance, making it suitable for a variety of applications including tires, construction, and adhesives. Additionally, its versatility in vulcanization and compatibility with blood enhances its utility in consumer products.