microencapsulation FINAL-1.pptx

- 1. 1

- 2. Definition of Micro encapsulation Reasons for Micro encapsulation Core and Coating Materials Mechanism of Drug Release Disadvantage Microcapsule Definition Classification Core and Coating Materials Manufacturing technique Marketed formulations 2

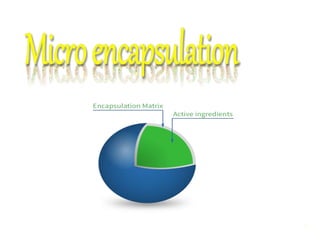

- 3. Microencapsulation may be defined as the process of surrounding or enveloping one substance within another substance on a very small scale, yielding capsules ranging from less than one micron to several hundred microns in size. Or Microencapsulation is the process by which tiny solid particles or droplets of liquid are surrounded or coated with a continuous film of polymeric material to produce capsules in the micrometer to millimetre range. The product obtained by this process is called as microcapsules. 3

- 5. It is mean of applying thin coating to small particle of solid or droplet of liquid & dispersion. Particle size: 50-5000 micron. It has 2 main phases: a) Core material b) Coating material Also known as microcapsule, microsphere, coated granules, pellets. 5

- 6. For sustained or prolonged drug release. For masking taste and odour of many drugs to improve patient compliance. For converting liquid drugs in a free flowing powder. To reduce toxicity and GI irritation Incompatibility among the drugs can be prevented by microencapsulation. The drugs, which are sensitive to oxygen, moisture or light, can be stabilized by microencapsulation 6

- 7. The material to be coated :- It may be liquid or solid Liquid core may be dissolved or dispersed material Composition of coating material: Drug or active constituent Additive like diluents Stabilizers Release rate enhancers 7

- 8. Inert substance which coats on core with desired thickness Compatible with the core material Stabilization of core material. Inert toward active ingredients. Controlled release under specific conditions. The coating can be flexible, brittle, hard, thin etc. Abundantly and cheaply available Composition of coating :- Inert polymer Plasticizer Colouring agent 8

- 9. Example of Coating materials: Gums:- Gum arabic, sodium alginate, carragenan Carbohydrates:- Starch, dextran, sucrose Celluloses:- Carboxymethylcellulose, methycellulose. Lipids:- Bees wax, stearic acid, phospholipids. Proteins:- Gelatin, albumin 9

- 10. 10

- 11. Mechanism of Drug Release Degradation Controlled monolith System Diffusion Controlled Monolith System Diffusion Controlled Reservoir System Erosion 11

- 12. 1)Degradation controlled monolithic system- Drug releases on degradation of matrix. 2)Diffusion controlled monolithic system- Drug released by diffusion then degradation of matrix occurs. 3)Diffusion controlled reservoir system- Drug from capsule diffuses then rate controlling membrane erodes. 4)Erosion-Due to pH and enzymatic hydrolysis. 12

- 13. To improve the flow properties. e.g. Thiamine, Riboflavine To enhance the stability. e.g. Vitamins To reduce the volatility of materials. e.g. Peppermint oil, Methyl salicylate To avoid incompatibilities. e.g. Aspirin and Chloramphenicol To mask the unpleasant taste and odour. e.g. Aminophylline, castor oil To convert liquids into solids. e.g. Castor oil, Eprazinone, To reduce gastric irritation. e.g. Nitrofurantoin, Indomethacin 13

- 14. Possible cross reaction between core and shell material. Difficult to achieve continuous and uniform film. Shelf life of hygroscopic drugs is reduced. More production costs. More skill and knowledge is required 14

- 15. 15

- 16. Applications of Microcapsules and Microspheres 36 1. AgriculturalApplications Reduce insect populations by disrupting their mating process. Protects the pheromone from oxidation and light during storage and release.

- 17. 37 2. Catalysis Safe handling, easy recovery, reuse and disposal at an acceptable economic cost. Metal species such as palladium (II) acetate and osmium tetroxide have been encapsulated in polyurea microcapsules and used successfully as recoverable and reusable catalysts without significant leaching and loss of activity.

- 18. 38 3. Food Industry Adding ingredients to food products to improve nutritional value can compromise their taste, colour, texture and aroma. Sometimes they slowly degrade and lose their activity, or become hazardous by oxidation reactions. Ingredients can also react with components present in the food system, which may limit bioavailability.

- 19. 39 4. Pharmaceutical Applications Potential applications of this drug delivery system are replacement of therapeutic agents (not taken orally today like insulin), gene therapy and in use of vaccines for treating AIDS, tumors, cancer and diabetes. The delivery of corrective gene sequences in the form of plasmid DNA could provide convenient therapy for a number of genetic diseases such as cystic fibrosis and hemophilia.

- 20. 40 Lupin has already launched in the market worlds first Cephalexin (Ceff-ER) and Cefadroxil (Odoxil OD) antibiotic tablets for treatment of bacterial infections. Aspirin controlled release version ZORprin CR tablets are used for relieving arthritis symptoms. Quinidine gluconate CR tablets are used for treating and preventing abnormal heart rhythms. Niaspan CR tablet is used for improving cholesterol levels and thus reducing the risk for a heart attack.

- 21. 41 Glucotrol (Glipizide SR) is an anti diabetic medicine used to control high blood pressure. Some of the applications of microencapsulation can be described in detail as given below: 1. Prolonged release dosage forms. 2. Prepare enteric-coated dosage forms selectively absorbed in the intestine rather than the stomach. 3. It can be used to mask the taste of bitter drugs. 4. To reduce gastric irritation.

- 22. 42 5. Used to aid in the addition of oily medicines to tablet dosage forms. To overcome problems inherent in producing tablets from otherwise tacky granulations. This was accomplished through improved flow properties. eg. The non-flowable multicomponent solid mixture of niacin, riboflavin, and thiamine hydrochloride and iron phosphate may be encapsulated and made directly into tablets.

- 23. 43 6. To protect drugs from environmental hazards such as humidity, light, oxygen or heat. eg. vitamin A and K have been shown to be protected from moisture and oxygen through microencapsulation. 7. The separations of incompatible substances, eg. pharmaceutical eutectics. The stability enhancement of incompatible aspirin- chlorpheniramine maleate mixture was accomplished by microencapsulating both of them before mixing.

- 24. 44 8. Microencapsulation can be used to decrease the volatility. 9. The hygroscopic properties of many core materials may be reduced by microencapsulation. 10.In the fabrication of multilayered tablet formulations for controlled release of medicament contained in medial layers of tableted particles. 11.Microencapsulation has also been used to decrease potential danger of handling of toxic or noxious substances. Such as fumigants, herbicides, insecticides and pesticides

- 25. 25

- 26. Microcapsule Definition Classification Core and Coating Materials Manufacturing technique Evaluation of microcapsule Marketed formulations 26

- 27. Microcapsule is a tiny capsule , containing material such as medicine, that is released when the capsule is broken , melted or dissolved. Microcapsules contain an active agent and surrounded polymeric shell or dispersed in polymeric matrix. Microcapsule size : 1 to 1000 micron Microcapsules can be of different structures 27

- 28. 28

- 29. Core Materials Purpose Final Product Acetaminophen Taste masking Tablet Potassium chloride Reduces gastric irritation Capsule Isosorbide dinitrate Sustained release Capsule 29

- 30. Category of Coating Material Examples Water soluble resins Gelatin, Polyvinylpyrrolidone (PVP). Water insoluble resins Ethyl cellulose, Polyethylene Waxes and lipids Paraffin, Carnauba, Beeswax Enteric resins Shellac, Zein 30

- 31. SL No. Physical Methods Chemical Methods A) Air Suspension Solvent Evaporation B) Pan Coating Polymerization C) Coarcervation Phase Separation D) Multi-orifice Centrifugal Process E) Spray Drying & Spray Congealing F) Fluidized Bed Technology 23

- 32. 24

- 33. Sl No . Method Applicable materials Particle Size Productio n scale Time Required Cost 1 Air Suspension Solid 35-5000 Pilot Scale High High 2 Pan Coating Solid 600- 5000 Pilot Scale High High 3 Coacervation and Phase Separation Solid and liquid 2-5000 Lab Scale Less Less 4 Multi-orifice centrifugal Solid and liquid 1-5000 Pilot Scale High High 5 Solvent Evaporation Solid and liquid 5-5000 Lab Scale Less Less 6 Spray Drying and Spray Congealing liquid 600 Pilot Scale High High 25

- 34. Within the coating chamber, particles are suspended on an upward moving air stream. Spraying of coating material on the air suspended particles. The cyclic process is repeated depending upon purpose of microencapsulation. Air stream serves to dry the product. 34

- 35. Microencapsulation by air suspension technique consist of the dispersing of solid particulate core materials in a supporting air stream and the spray coating on the air suspended particles. Within the coating chamber, particles are suspended on an upward moving air stream. 35

- 36. The design of the chamber and its operating parameters effect a recalculating flow of the particles through the coating zone portion of the chamber, where a coating material, usually a polymer solution, is spray applied to the moving particles. 36

- 37. D u r i n g e ach pass through the coating zone, the core material receives an increment of coating material. The cyclic process is repeated, perhaps several hundred times during processing, depending on the purpose of microencapsulation the coating thickness desired or whether the core material particles are thoroughly encapsulated. The supporting air stream also serves to dry the product while it is being encapsulated. Drying rates are directly related to the volume temperature of the supporting air stream. 29

- 39. Concentration of Coating materials Solubility , Surface area, density, melting point and Volatility. Application rate of coating materials Temperature of air stream. The amount of required to fluidized the core materials. 39

- 40. The particles are tumbled in a pan while the coating material is applied slowly as solution or atomized spray to the core. To remove the coating solvent, warm air is passed over the coated materials. Medicaments are usually coated onto nonpareil sugar seeds and then coated with polymers 40

- 42. Solid particles are mixed with a dry coating material. The temperature is raised so that the coating material melts and encloses the core particles, and then is solidified by cooling. Or, the coating material can be gradually applied to core particles tumbling in a vessel rather than being wholly mixed with the core particles from the start of encapsulation. 42

- 43. Advantage Disadvantage Suitable to larger particle Time consuming Sustained release preparation High material loss 43

- 44. Pan Coating Equipment 44

- 45. Simple coacervation Complex coacervation A desolvation agent is addedfor phase separation It involves complexation between two oppositely charged polymers. Steps involved in this process are:- 1)Formation of three immiscible phases. 2)Deposition of liquid coating material upon the core material. 3) Rigidization of coating. 45

- 46. Formation of three immiscible phases; a liquid manufacturing phase, a core material phase and a coating material phase. Deposition of the liquid polymer coating on the core material. Rigidizing the coating usually by thermal, cross linking or desolvation techniques to form a microcapsule. In step 2, the deposition of the liquid polymer around the interface formed between the core material and the liquid vehicle phase. In many cases physical or chemical changes in the coating polymer solution can be induced so that phase separation of the polymer will occur. 46

- 47. Droplets of concentrated polymer solution will form and coalesce to yield a two phase liquid-liquid system. In cases in which the coating material is an immiscible polymer of insoluble liquid polymer it may be added directly. Also monomers can be dissolved in the liquid vehicle phase and subsequently polymerized at interface. Equipment required for microencapsulation this method is relatively simple; it consists mainly of jacketed tank with variable speed agitator. 47

- 48. Simple Coacervation process 40

- 50. Various methods to obtain three immiscible phases 50 1) Temperature change 2) Incompatible PolymerAddition 3) Non-SolventAddition 4) SaltAddition 5) Polymer-Polymer Interaction(Complex Coacervation)

- 51. Temperature Change:- Changing temperature of polymer solution, Example:- Ethyl cellulose in cyclohexane. Incompatible polymer addition :- Addition of incompatible polymer to the polymer solution , e.g. Addition of polybutadiene to the solution of ethyl cellulose in toluene. Non Solvent Addition:- e.g. Addition of isopropyl ether to methyl ethyl ketone solution of cellulose acetate butyrate. Addition of Salt :- e.g. Addition of Sodium sulphate solution to gelatin solution in vitamin encapsulation Polymer-polymer interaction:- e.g. Interaction of gum arabic and gelatin at their isoelectric point 51

- 52. The Southwest Research Institute (SWRI) has developed a mechanical process for producing microcapsules that utilizes centrifugal forces to hurl a core material particle trough an enveloping microencapsulation membrane thereby effecting mechanical microencapsulation. Processing variables include the rotational speed of the cylinder, the flow rate of the core and coating materials, the concentration and viscosity and surface tension of the core material. 52

- 53. The multiorifice-centrifugal process is capable for microencapsulating liquids and solids of varied size ranges, with diverse coating materials. The encapsulated product can be supplied as slurry in the hardening media or as a dry powder. Production rates of 50 to 75 pounds per our have been achieved with the process. 53

- 54. Cylinder Rotating Speed Core and Coating materials Flow Rate Viscosity Surface tension Concentration ofCore material 54

- 55. Advantage:- Encapsulates both solid and liquid materials. Production rate is more. 55

- 56. 56

- 57. Spray Drying : Microencapsulation by spray-drying is a low- cost commercial process which is mostly used for the encapsulation of fragrances, oils and flavours. Steps: 1- Core particles are dispersed in a polymer solution and sprayed into a hot chamber. 57

- 58. 2- The shell material solidifies onto the core particles as the solvent evaporates. The microcapsules obtained are of Polynuclear or matrix type. The coating solidification effected by rapid evaporating of solvent in which coating material is dissolved. 58

- 59. Spray Congealing: This technique can be accomplished with spray drying equipment when the protective coating is applied as a melt. 1- the core material is dispersed in a coating material melt. 59

- 60. 2- Coating solidification (and microencapsulation) is accomplished by spraying the hot mixture into a cool air stream. - e.g. microencapsulation of vitamins with digestible waxes for taste masking. The coating solidification is effected by thermally congealing a molten coating material. The removal of solvent is done by sorption, extraction or evaporation technique 60

- 61. 53 Spray Drying

- 62. 54 SPRAY DRYING &CONGEALING ( COOLING)

- 63. 63

- 64. The liquid coating is sprayed onto the particles and the rapid evaporation helps in the formation of an outer layer on the particles. The thickness and formulations of the coating can be obtained as desired. Different types of fluid-bed coaters include top spray ,bottom spray, and tangential spray 64

- 65. In the top spray system the coating materials is sprayed downwards onto the fluid bed such that as the solid or porous particle move to coating region they become encapsulated. The bottom spray is also known as “Wurster`s Coater” in reorganization of its development by Prof. D.E. Wurster. 65

- 66. The tangential spray consists of a rotating disc at the bottom of the coating chamber , with the same diameter as the chamber. During the process the disc is raised to create a gap between edge of the chamber and the disc. The tangential nozzle is placed above the rotating disc through which coating material is released . The particle move through the gap into the spraying zone and are encapsulated. As they travel a minimum distance there is higher yield of encapsulated particles. 66

- 67. 67

- 68. Core material Dissolved Or Dispersed Coating polymer solution WithAgitation Liquid Manufacturing Vehicle Phase Heating (If necessary) Evaporation of Polymer solvent Microencapsulation 60

- 69. This technique has been used by companies including the NCR Company, Gavert Photo production NV, and Fuji Photo Film Co. Ltd. To produce microcapsule. In this, Volatile Solvent is Dissolved in microcapsule coating material, which is immiscible with the liquid manufacturing vehicle phase. 69

- 70. The core material to be encapsulated is dispersed in the solution of coating polymer .Continuous agitation is carried out, and then core coating material mixture is dispersed in the liquid manufacturing vehicle phase to give specific size of microcapsule. Then the solvent evaporate from the polymer solution after heating the mixture. The solvent evaporation technique is used to formulate various types of microcapsule, for example, evolution of sucrose esters as an alternative surfactants in microencapsulation of proteins by the solvent evaporation method. 70

- 72. The method involve the reaction of monomeric unit located at the interface existing between a core material substance and continuous phase in which the core material is disperse. The core material supporting phase is usually a liquid or gas, and therefore polymerization reaction occur at liquid-liquid, liquid-gas, solid-liquid, or solid-gas interface. E.g. In the formation of polyamide (Nylon) polymeric reaction occurring at liquid-liquid interface existing between aliphatic diamine & dicarboxylic acid halide. 72

- 73. Preparation of the polymerization mixture Drug Monomer(s) (e.g. acrylamide) Cross-linker (e.g.Methylenebisacrylamide) + + Initiation of Polymerization Monodisoerse Latex Formation by Polymer Precipitation Recovery of Polymeric Microparticles Alcohol Addition of the alcoholic solution of the initiator 8hrs reaction time 73

- 74. Polymerization Interfacial Polymerization In-situ Polymerization 74

- 75. 75

- 76. 76

- 77. 77

- 78. 78

- 79. 79

- 80. 80

- 81. 73 Difference

- 82. A fluid stream of liquid core and shell materials ispumped through concentric tubes and forms droplets under the influence of vibration. 82

- 83. 83

- 84. 1)Percentage Yield :- The total amount of microcapsules obtained was weighed and the percentage yield calculated taking into consideration the weight of the drug and polymer. Percentage yield = Amount of microcapsule obtained / Theoretical Amount×100 2)Scanning electron microscopy :- Scanning electron photomicrographs of drug loaded ethyl cellulose microcapsules were taken. A small amount of microcapsules was spread on gold stub and was placed in the scanning electron microscopy (SEM) chamber. The SEM photomicrographs was taken at the acceleration voltage of 20 KV. 84

- 85. 3)Particle size analysis :- For size distribution analysis, different sizes in a batch were separated by sieving by using a set of standard sieves. The amounts retained on different sieves were Encapsulation efficiency was 85 weighed . 4)Encapsulation efficiency:- calculated using the formula. Encapsulation efficiency = Actual Drug Content / Theoretical Drug Content ×100

- 86. 5) Estimation of Drug Content:- Drug content in the microcapsules was calculated by UV spectrophotometric method. The method was validated for linearity, accuracy and precision. A sample of microcapsules equivalent to 100 mg was dissolved in 25 ml ethanol and the volume was adjusted up to 100 ml using phosphate buffer of pH 7.4. The solution was filtered through Whatman filter paper. Then the filtrate was assayed for drug content by measuring the absorbance at specific wavelength after suitable dilution. 86

- 87. 6) Invitro Drug release Studies 87 Drug release was studied by using USP type II dissolution test apparatus in Phosphate buffer of pH 7.4 (900 ml). The paddle speed at 100 rpm and bath temperature at 37 ± 0.5°c were maintained through out the experiment. A sample of microcapsules equivalent to 100 mg of drug was used in each test. Aliquot equal to 5ml of dissolution medium was withdrawn at specific time interval and replaced with fresh medium to maintain sink condition. Sample was filtered through Whatman No. 1 filter paper and after suitable dilution with medium; the absorbance was determined by UV spectrophotometer at specific wavelength. All studies were conducted in triplicate (n=3). The release of drug from marketed sustained release preparation was also studied to compare with release from microcapsules.

- 88. 7) Diffusion:- Diffusion is a common mechanism of drug release in which dissolution fluid penetrates the shell and then core material comes in contact with the fluid and leak out through the interstitial channels or pores. 88

- 89. 8) Thermal Analysis:- It is use for determination of drug performance after encapsulation in terms of change of drug behaviour and studied by DSC. 9)Molecular Weight:- Molecular Weight of the microcapsule is done by Gel Permeation Chromatography. 89

- 90. SL No. Brand Name Generic Name Category of Drug 1 Lupin Cafedroxil Antibiotic 2 Zorprine CR Aspirin Anti - arthritic 3 Glipizide SR Glucotrol Anti diabetic 85

- 91. Micro encapsulation ppt by – SANATABASSUM A Review on Microcapsules :- Azagheswari, BinilKuriokase, Sathireddy Padma and S. Padma Priya Micro-encapsulation : at Crossroads of Art, Science and Technology MICROENCAPSULATION: A REVIEW JYOTHI SRI.S* , A.SEETHADEVI , K.SURIA PRABHA , P.MUTHUPRASANNAAND ,P.PAVITRA 91

- 92. 92