Computerized maintenance management system (cmms)

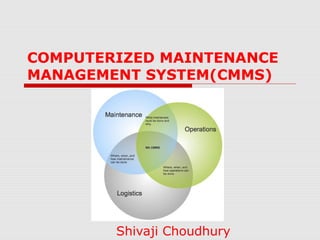

- 2. COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM(CMMS) A CMMS software package maintains a computer database of information about an organization’s maintenance operations. This information is intended to help maintenance workers do their jobs more effective.

- 3. Benefits Achieving high efficiency. Minimizing usage of parts and labor. Maximizing usage of equipments and minimizing downtime. Maximizing equipments lifetime and replacement period. Minimizing maintenance and operation costs. Maximizing profits. Raising performance levels. Allows the safe and efficient functioning.

- 4. The CMMS enables management to: Schedule preventive and predictive maintenance procedures, and parts and labor utilization for maintenance tasks. Project and monitor downtime and causes. Project and monitor costs, repairs, and usage of spare parts and labor. Analyze failures, costs, maintenance procedures, and resource usage.

- 5. Functional Requirements of CMMS 1. Asset Management & Asset Register Function 2. Inventory Management Function 3. Work Order Function 4. Job Planning Function 5. Resource Planning Function 6. Schedule Planning Function 7. Maintenance management 8. Purchasing Function 9. Reporting Functions

- 7. 1. Asset Management & Asset Register Function Location details of equipments and it’s hierarchy. Building spare parts and sub-assembly catalogues . Links to inventory management and purchase functions.

- 8. 2. Inventory Management Function Tracking of stocked and non-stocked items through multiple stores. Tracking of items, costs and balances by bin, lot and storeroom. Stock replenishment when inventory falls below minimum levels ABC and XYZ analysis .

- 9. 3. Work Order Function Viewing comprehensive and detailed planning information such as • Work Plans • Target and scheduled date • Costs • Labour, materials, Skill set / crafts, • Failure analysis Predictive maintenance. Scheduling of work orders based on real time criticality and logistics.

- 10. 4. Job Planning Function Tracking of costs by operation or job plan. Linking job plans sequentially, each with it’s own parts, labour and tool estimates.

- 11. 5. Resource Planning Function Resource function shall allow to maintain detailed resource information to plan and analyze maintenance work related to company, service contract, tools etc.

- 12. 6. Schedule Planning Function Scheduling function shall enable to forecast future preventive maintenance dates for resource planning.

- 13. 7. Maintenance Management Allows each asset / equipment to have a defined maintenance profile Helps to schedule planned preventive and predictive maintenance routines. Control maintenance procedures.

- 15. 8. Purchasing Function Creation of purchase requisitions or purchase orders either from scratch or from the inventory or work order modules. Analyzing of vendor performance before ordering of part. Auto re-orders generation for the spares, when stock falls below re-order level.

- 16. 9. Reporting Functions Standard Reports-Generation of standard reports on work orders, safety plans, inventory values and other critical points about maintenance operations. Report types- Capabilities shall include columnar reports, forms, Bar Charts, Pie Charts, Cross tabs etc.

- 17. CMMS- Computerized Maintenance Management System ERP –Enterprise Resource Planning EAM -Enterprise Asset Management

- 18. ERP or CMMS – fundamental differences ERP ERP systems are built around accounting. ERP systems often takes fixed asset module in accounting as starting point. Covering basic maintenance functionality. CMMS CMMS systems are developed with the maintenance processes in focus. Deeper functionality for maintenance specific tasks.

- 19. CMMS in ISA 95 - Control Hierarchy Levels CMMS

- 20. Asset optimization and maintenance (CMMS) support

- 21. Case study :CMMS for bus fleet: computer network

- 22. Case study : CMMS for bus fleet: various modules

- 23. Case study :CMMS for bus fleet: inventory module

- 24. Case study : CMMS for bus fleet: Maintenance management module

- 25. THANKING YOU