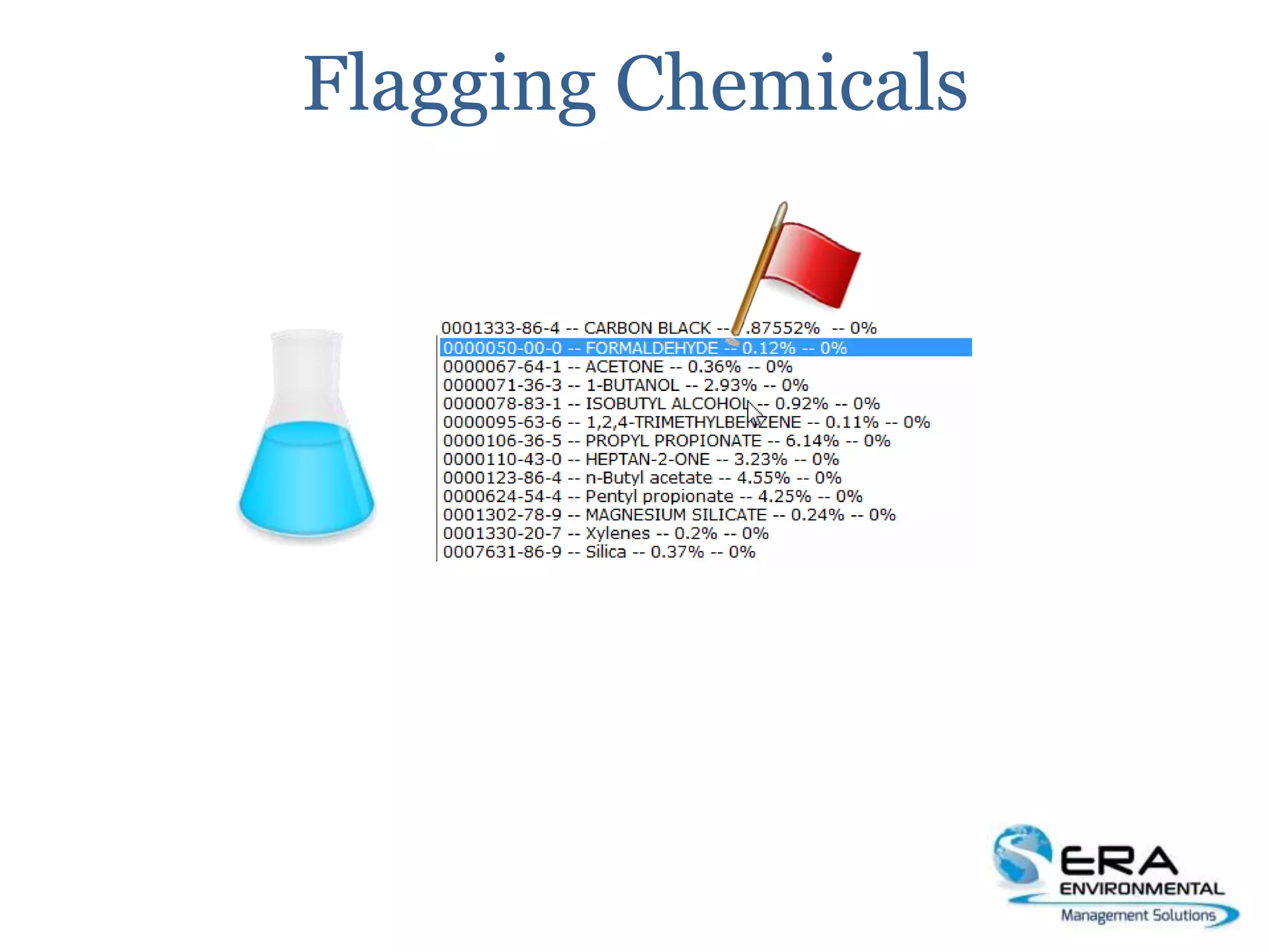

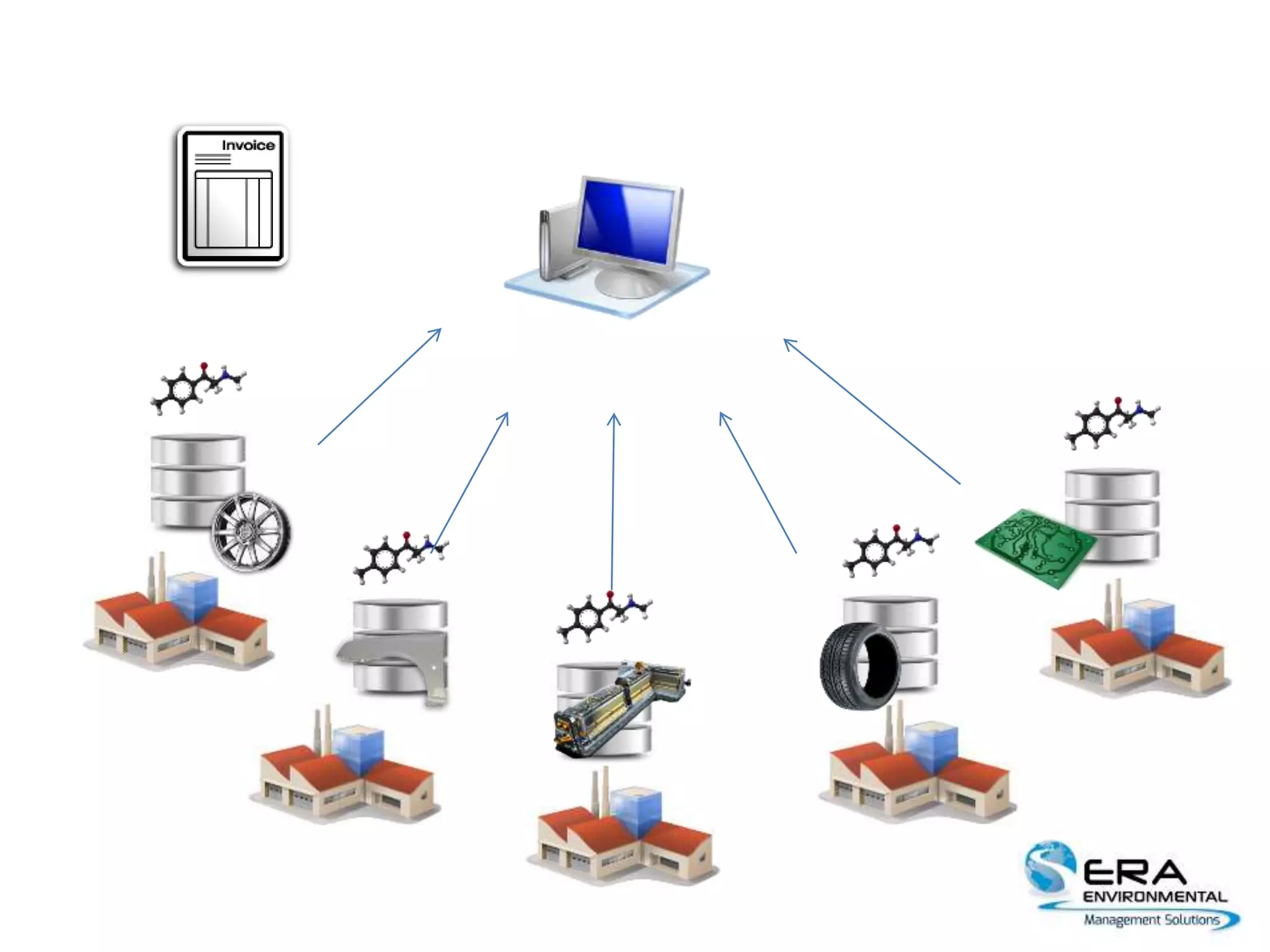

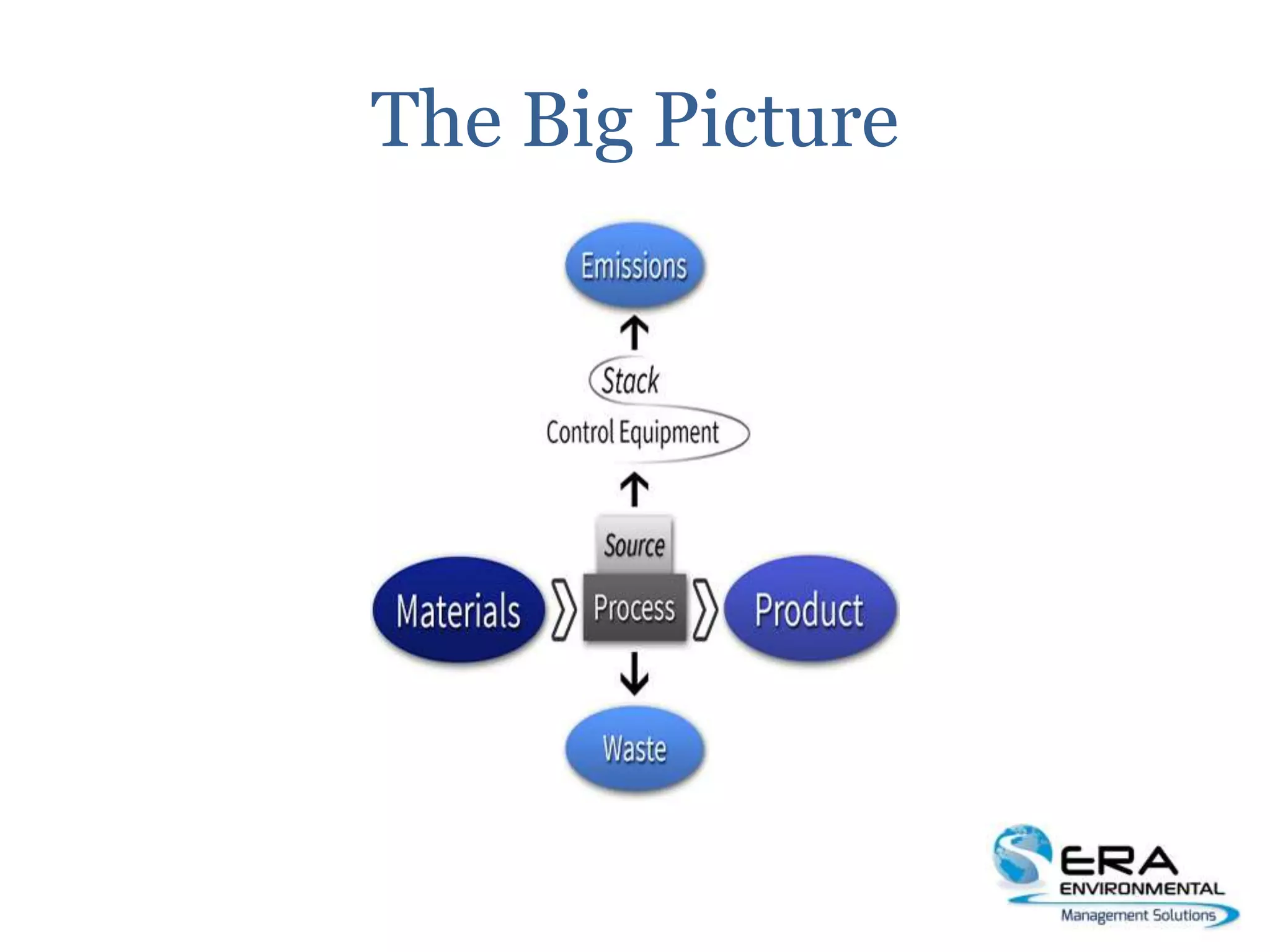

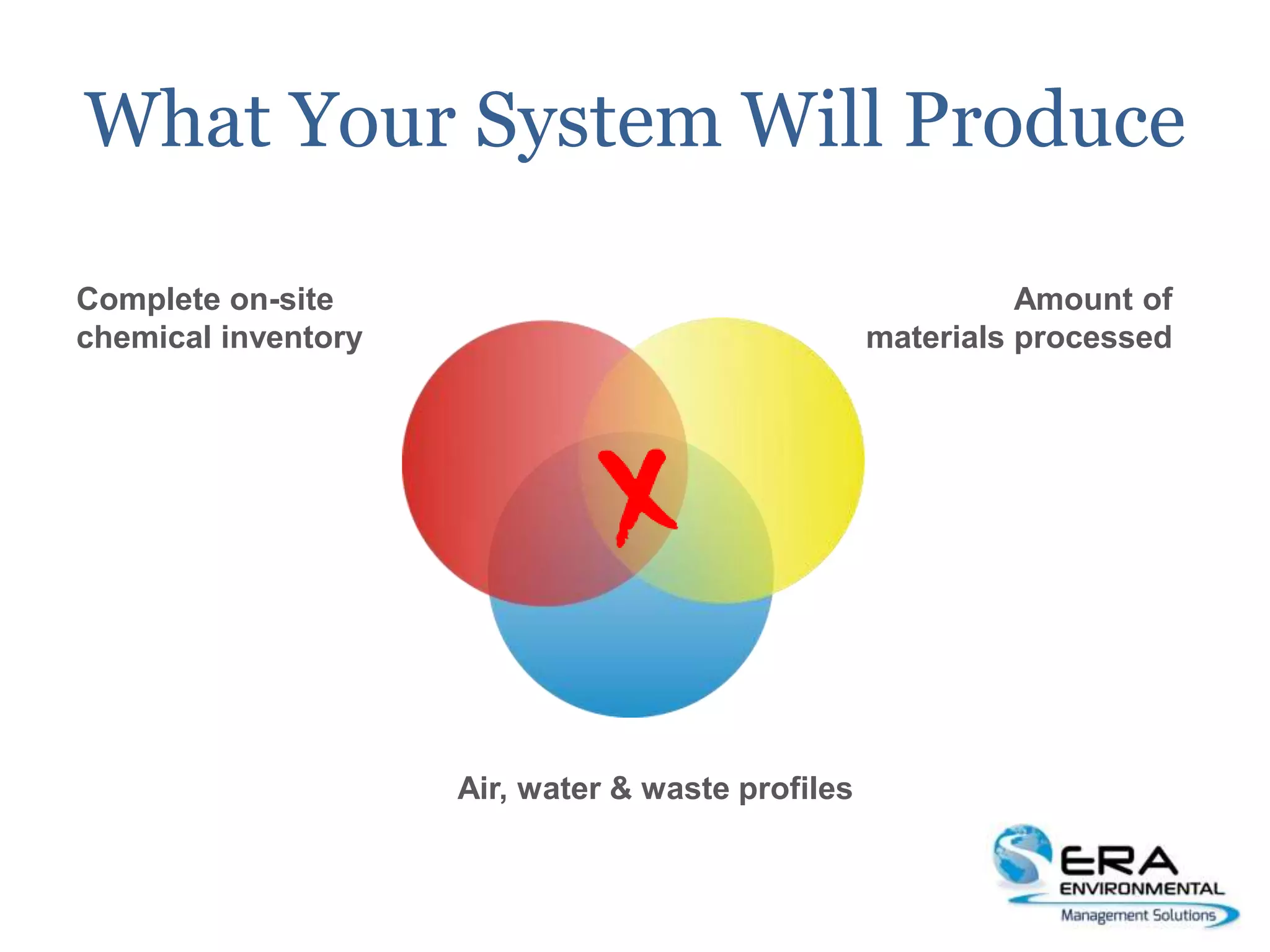

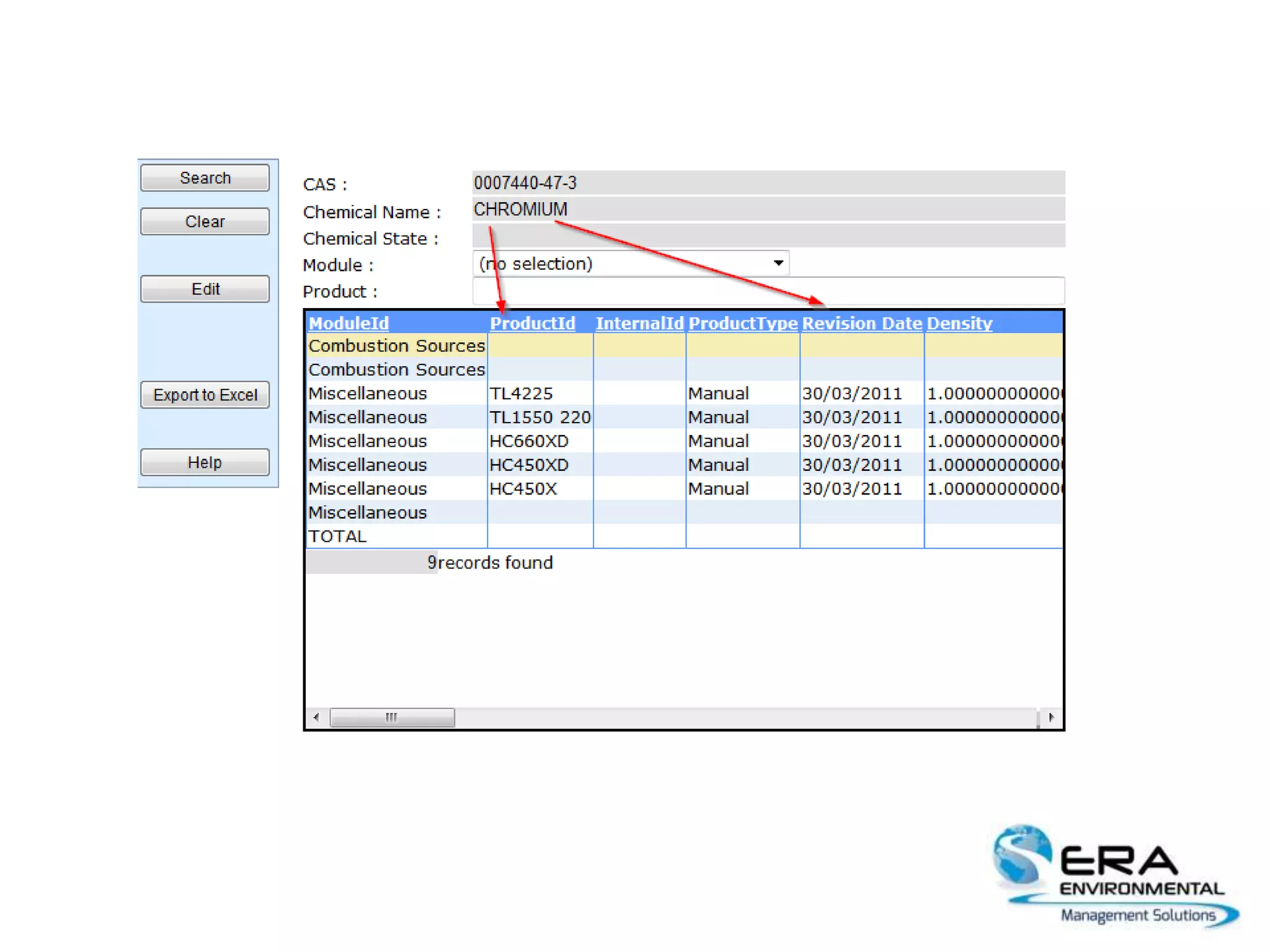

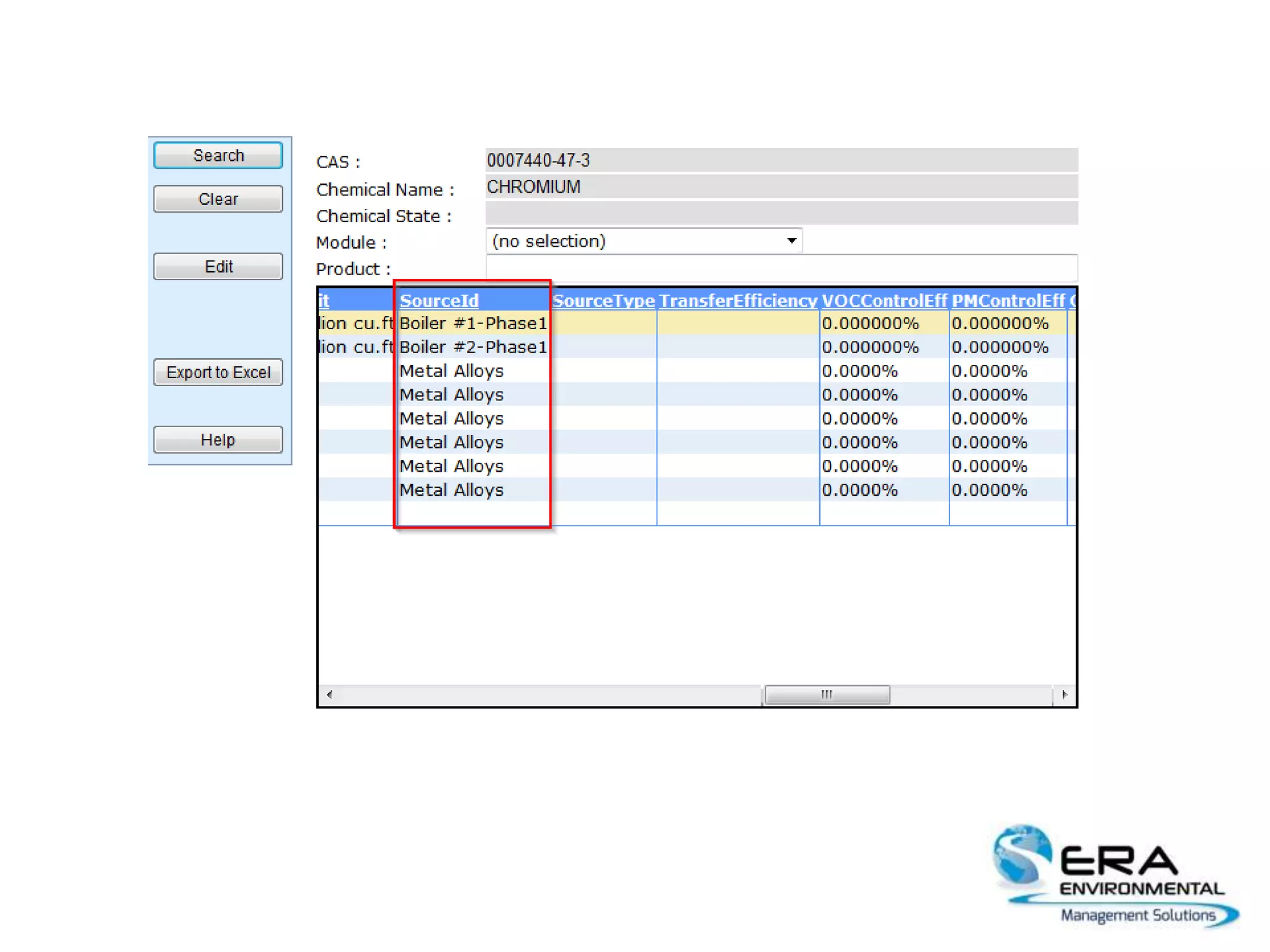

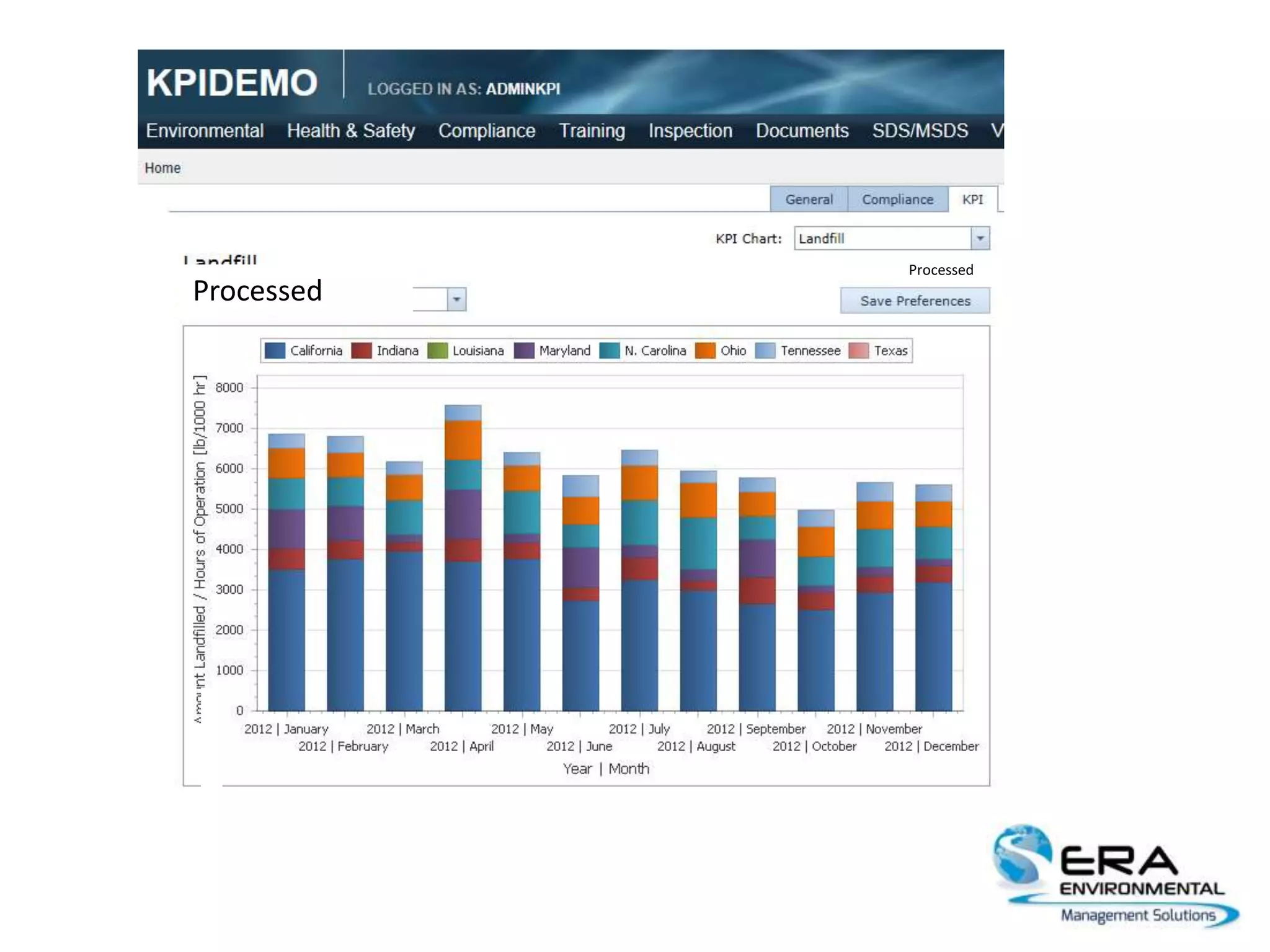

The document outlines the process for conducting a world-class environmental audit, emphasizing the importance of accurate record keeping and understanding regulatory requirements. It details key environmental reports, critical data tracking for materials and processes, and the significance of effective communication with auditors. The presentation encourages organizations to adopt a centralized and efficient management system to improve compliance and reduce risks associated with environmental management.