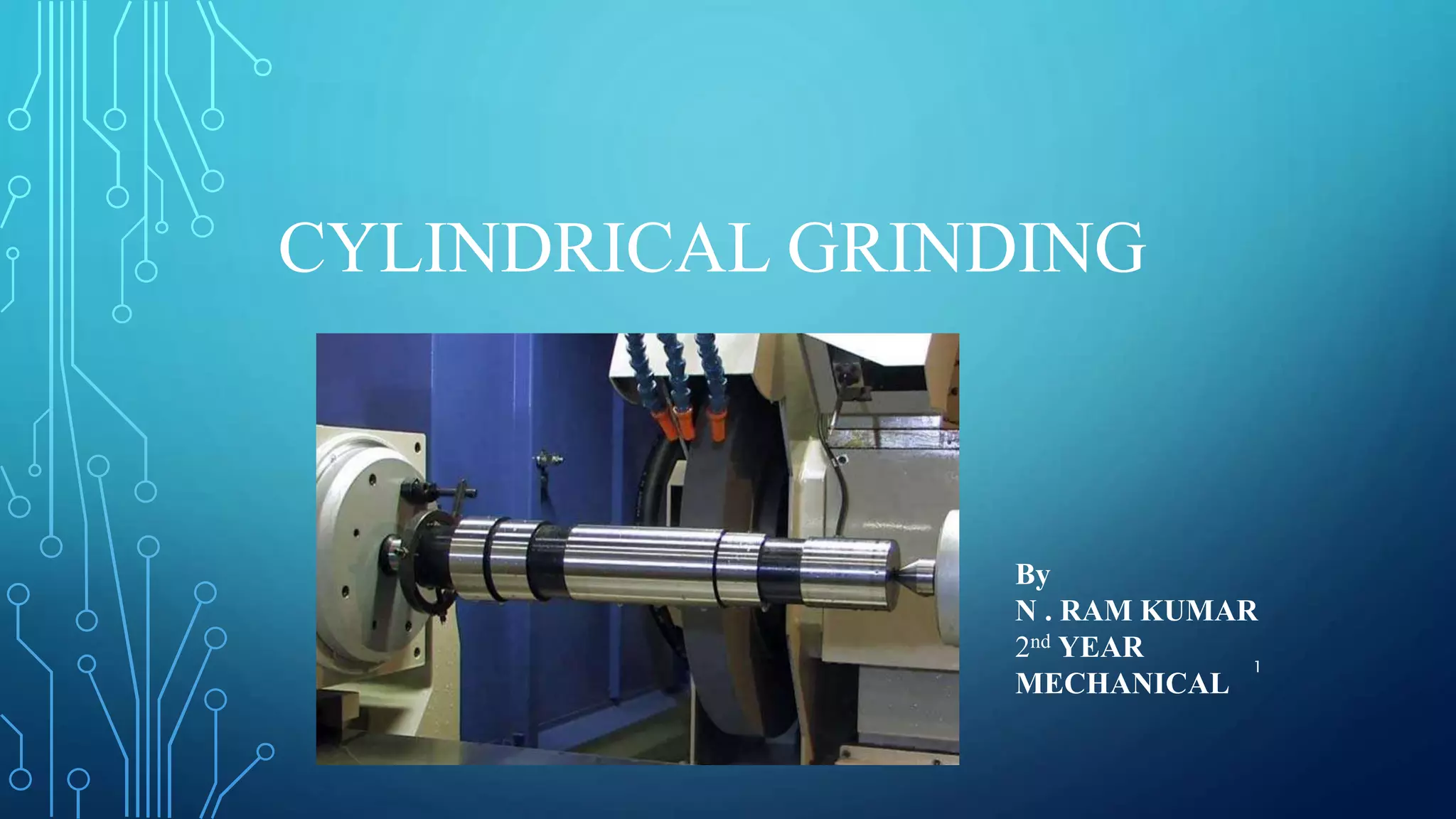

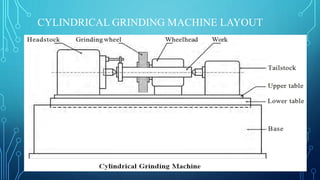

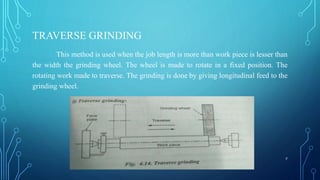

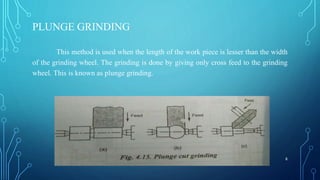

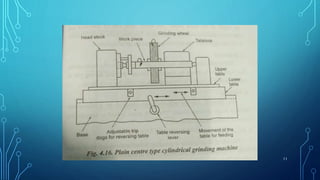

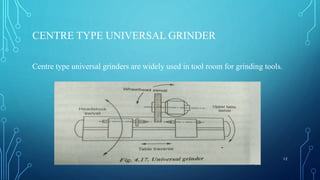

The document provides an overview of cylindrical grinding, covering its principles, operations, and types of machines. It describes two main operations: traverse grinding and plunge grinding, along with the specific types of cylindrical grinding machines, namely plain centre type and centre type universal grinders. Both machine types have distinct features and applications in producing external cylindrical surfaces.