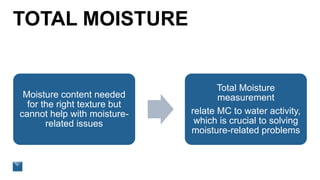

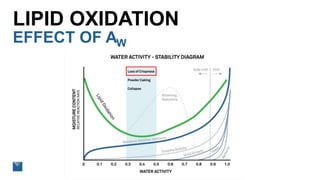

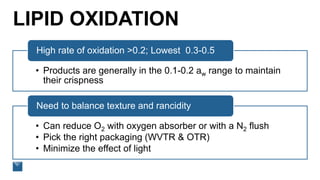

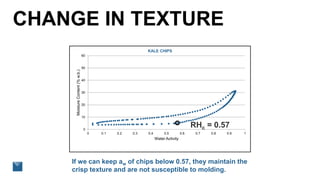

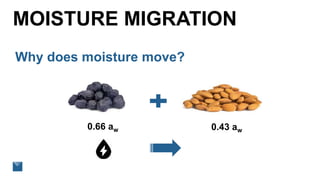

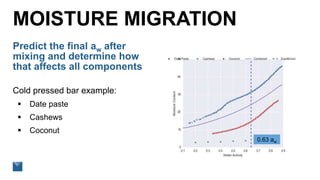

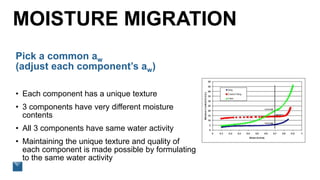

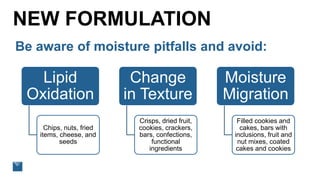

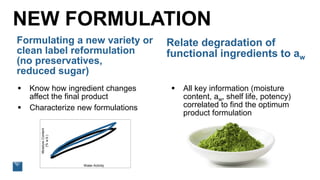

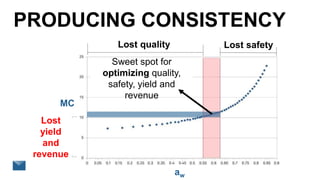

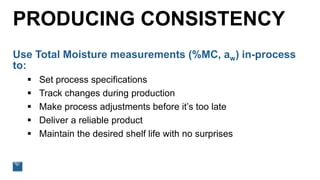

The document discusses moisture management in snack foods, highlighting issues such as rancidity, texture changes, and moisture migration that can affect product quality and shelf life. It emphasizes the importance of water activity (aw) and total moisture measurements in formulating consistent and safe products while addressing problems like lipid oxidation and packaging impacts. Recommendations for maintaining desired texture and preventing moisture-related issues are provided, stressing the need for careful formulation and monitoring during production.