Siemens catalog hmi-touch panel tp170 a, tp170 b operator panel op170 b

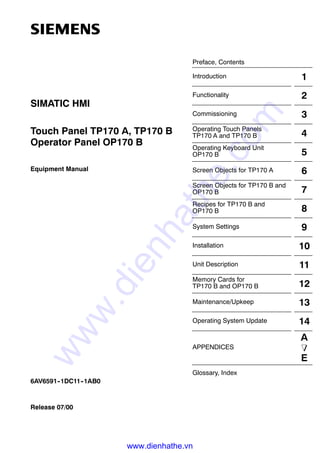

- 1. Preface, Contents Introduction 1 Functionality 2 Commissioning 3 Operating Touch Panels TP170 A and TP170 B 4 Operating Keyboard Unit OP170 B 5 Screen Objects for TP170 A 6 Screen Objects for TP170 B and OP170 B 7 Recipes for TP170 B and OP170 B 8 System Settings 9 Installation 10 Unit Description 11 Memory Cards for TP170 B and OP170 B 12 Maintenance/Upkeep 13 Operating System Update 14 APPENDICES A E Glossary, Index Release 07/00 6AV6591--1DC11--1AB0 Touch Panel TP170 A, TP170 B Operator Panel OP170 B Equipment Manual SIMATIC HMI www.dienhathe.vn www.dienhathe.com

- 2. Index-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 ! Warning indicates that death, severe personal injury or substantial property damage can result if proper precau- tions are not taken. ! Caution indicates that minor personal injury or property damage can result if proper precautions are not taken. Note draws your attention to particularly important information on the product, handling the product, or to a particular part of the documentation. Qualified Personnel Equipment may be commissioned and operated only by qualified personnel. Qualified personnel within the meaning of the safety notices in this manual are persons who are authorized to commission, ground and identify equipment, systems and circuits in accordance with safety engineering standards. Correct Usage Note the following: ! Warning The equipment may be used only for the applications stipulated in the catalog and in the technical descrip- tion and only in conjunction with other equipment and components recommended or approved by Sie- mens. Startup must not take place until it is established that the machine, which is to accommodate this compo- nent, is in conformity with the guideline 89/392/EEC. Faultless and safe operation of the product presupposes proper transportation, proper storage, erection and installation as well as careful operation and maintenance. Trademarks The registered trademarks of Siemens AG are listed in the Preface. Some of the other designations used in these documents are also registered trademarks; the owner’s rights may be violated if they are used be third parties for their own purposes. Impressum Editor and Publisher: A&D PT1. Safety Guidelines This manual contains notices which you should observe to ensure your own personal safety, as well as to protect the product and connected equipment. These notices are highlighted in the manual by a warning triangle and are marked as follows according to the level of danger: We have checked the contents of this manual for agreement with the hard- ware and software described. Since deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the data in this manual are reviewed regularly and any necessary corrections included in subsequent editions. Suggestions for improvement are welcomed. Disclaimer of LiabilityCopyright Siemens AG 2000 All rights reserved The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will be liable for damages. All rights, including rights created by patent grant or registration of an utility model or design, are reserved. Siemens AG Automation & Drives SIMATIC Human Machine Interface Postfach 4848, D-90327 Nuernberg E Siemens AG 2000 Technical data subject to change. Siemens Aktiengesellschaft Order no: 6AV6591--1DC11--1AB0 www.dienhathe.vn www.dienhathe.com

- 3. i TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Preface This manual The TP170 A, TP170 B, OP170 B equipment manual is part of the SIMATIC HMI documentation. It provides operation, installation, configuration and maintenance personnel with information concerning installation, functionality, operation and technical design of the SIMATIC operating units TP170 A, TP170 B and OP170 B. An overview of the entire SIMATIC HMI documentation is provided in Appendix E. Organization of the manual The manual is organized into the following chapters: Chapter Contents 1 - 2 Overview of the features and functional scope of the unit 3 - 7 Commissioning and operation 8 Recipes for TP170 B and OP170 B 9 System settings 10 - 13 Mechanical and electrical installation, unit description, retrofitting of options as well as maintenance and upkeep. 14 Informationen on updating the operating system. Appendix S Technical Data S Interface Assignments S System Messages S ESD Guidelines S SIMATIC HMI Documentation www.dienhathe.vn www.dienhathe.com

- 4. Preface ii TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Conventions The following cionventions are used throughout this manual: Motor off Text in the operating unit display is presented in this typewriter font. Tag Symbolic names representing tag values on the screen are presented in this italic typewriter font. Screens Functions available for selection are presented in this italic font. ESC The names of keys and buttons are displayed in a different font. History The various releases of this manual correspond to the following versions of the ProTool CS configuration software: Edition Comment ProTool Version 12/99 First release of the TP170 A equipment manual From V5.2 07/00 Extensions to the TP170 B and OP170 B units From V5.2 + SP2 Trademarks The following names are registered trademarks of the Siemens AG: S SIMATICR S SIMATIC HMIR S HMIR S ProToolR S ProTool/LiteR S ProTool/ProR S SIMATIC Multi PanelR S SIMATIC Multifunctional PlatformR S MP 270R S ProAgentR www.dienhathe.vn www.dienhathe.com

- 5. Preface iii TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Other support In the case of technical queries, please contact the Siemens representatives in the subsidiaries and branches responsible for your area. SIMATIC Customer Support Hotline Available worldwide, at all times: Johnson City Nuernberg Singapur SIMATIC Basic Hotline Nuernberg Johnson City Singapur SIMATIC BASIC Hotline SIMATIC BASIC Hotline SIMATIC BASIC Hotline Local time Mo - Fr 7:00 to 17:00 Local time Mo - Fr 8:00 to 19:00 Local time Mo - Fr 8:30 to 17:30 Telephone: +49 (911) 895-7000 Telephone: +1 423 461-2522 Telephone: +65 740-7000 Fax: +49 (911) 895-7002 Fax: +1 423 461-2231 Fax: +65 740-7001 E-Mail: simatic.support@ nbgm.siemens.de E-Mail: simatic.hotline@ sea.siemens.com E-Mail: simatic.hotline@ sae.siemens.com.sg SIMATIC Premium Hotline (charged, only with SIMATIC Card) Time: Mo - Fr 0:00 to 24:00 Telephone: +49 (911) 895-7777 Fax: +49 (911) 895-7001 www.dienhathe.vn www.dienhathe.com

- 6. Preface iv TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 SIMATIC Customer Online Services SIMATIC Customer Support offers comprehensive additional information concerning SIMATIC products through its Online services as follows: S Up-to-date general information is provided -- in Internet under http://www.ad.siemens.de/simatic -- via the Fax-Polling under 08765-93 02 77 95 00 S Up-to-date product information and downloads for practical use can be found: -- in Internet under http://www.ad.siemens.de/support/html-00/ Abbreviations The abbreviations used in this user’s guide have the following meaning: AG (PLC) Programmable Logic Controller AM Alarm Message ANSI American National Standards Institute AS 511 Protocol of the PU interface to SIMATIC S5 ASCII American Standard Code for Information Interchange CCFL Cold Cathode Fluorescence Lamp CF Compact Flash CPU Central Processing Unit CSV Comma Separated Values DP Decentralized Periphery DRAM Dynamic Random Access Memory DSN Data Source Name ESD Electrostatically Sensitive Device EM Event Message EMC Electromagnetic compatibility HMI Human Machine Interface IF Interface LCD Liquid Crystal Display LED Light Emitting Diode MP Multi Panel MPI Multipoint Interface (SIMATIC S7) OP Operator Panel PC Personal Computer PCL Printer Control Language PLC Programmable Logic Controller www.dienhathe.vn www.dienhathe.com

- 7. Preface v TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 PU Programming Unit PPI Point to Point Interface (SIMATIC S7) RAM Random Access Memory SRAM Static Random Access Memory STN Super Twisted Nematic TCP/IP Transmission Control Protocol/Internet Protocol TFT Thin Film Transistor TTL Transistor--Transistor Logic TP Touch Panel A list of all the specialist terms together with their explanations is provided in the Glossary at the end of this guide. www.dienhathe.vn www.dienhathe.com

- 8. Preface vi TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 www.dienhathe.vn www.dienhathe.com

- 9. vii TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Contents 1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Functionality 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Commissioning 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 Initial Startup 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 Recommissioning 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3 Options for Download Mode 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4 Testing a Project on the Operating Unit 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 Download Back (TP170 B and OP170 B) 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 Backup/Restore the Internal Flash Memory (TP170 B and OP170 B) 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Operating Touch Panels TP170 A and TP170 B 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1 Operating Touch Elements 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1.1 Enter Numeric Values 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1.2 Enter Alphanumeric Values 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1.3 Enter Symbolic Values on the TP170 B 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.2 Calling in Help Text on the TP170 B 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Operating Keyboard Unit OP170 B 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1 Integrated Keyboard 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2 Key Combinations 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3 Entering Values 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3.1 Enter Numeric Values 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3.2 Enter Alphanumeric Values 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3.3 Enter Symbolic Values 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.4 Call Help Text 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . www.dienhathe.vn www.dienhathe.com

- 10. Contents viii TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 6 Screen Objects for TP170 A 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 General Operation 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1.1 Operating Screens 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1.2 Logging On and Off from the Operating Unit 6-3. . . . . . . . . . . . . . . . . . . . . . . . 6.2 Overview of Screen Objects 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3 Input Field for Date/Time 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4 Input Field for Confidential Password Entry 6-5. . . . . . . . . . . . . . . . . . . . . . . . . 6.5 Status Button 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6 Messages 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 Bar graphs 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Screen Objects for TP170 B and OP170 B 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1 General Operation 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1.1 Operating screens 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1.2 Logging On and Off from the Operating Unit 7-5. . . . . . . . . . . . . . . . . . . . . . . . 7.2 Overview of Screen Objects 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3 Input Field for Date/Time 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4 Input Field for Confidential Password Entry 7-9. . . . . . . . . . . . . . . . . . . . . . . . . 7.5 Buttons 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6 Status Button 7-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.7 Switch 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8 Messages 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.1 ALARM_S 7-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.2 Message Line 7-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.3 Message Window 7-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.4 Message Page 7-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.5 Message Buffer 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.6 Message View 7-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8.7 Simple Message View 7-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 Bar Graphs 7-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.10 Trend View 7-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.11 Date/Time 7-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.12 Password List 7-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Recipes for TP170 B and OP170 B 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1 Overview 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.2 Recipe Configuration 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3 Editing Data Records 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3.1 Recipe View 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3.2 Recipe Screens 8-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3.3 Functions and PLC jobs 8-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3.4 Import/Export Data Records 8-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3.5 Reaction on Changing the Recipe Structure 8-20. . . . . . . . . . . . . . . . . . . . . . . . www.dienhathe.vn www.dienhathe.com

- 11. Contents ix TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 9 System Settings 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1 TP170 A Settings 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1.1 Setting an Operating Mode 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1.2 Screen Settings 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1.3 Set Screen Saver Response Time 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2 Settings for TP170 B and OP170 B 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2.1 Set Language 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2.2 Setting an Operating Mode 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2.3 Screen Settings 9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.2.4 Control Panel Settings 9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Installation 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1 Mechanical Installation 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2 Electrical Installation 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2.1 Connect Configuration Computer 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2.2 Connect PLC 10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2.3 Connecting a Printer to TP170 B and OP170 B 10-11. . . . . . . . . . . . . . . . . . . . . . 11 Unit Description 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1 TP170 A 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1.1 Dimensions and mounting area 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1.2 Connection elements 11-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1.3 Communication options 11-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.2 TP170 B 11-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.2.1 Dimensions and mounting area 11-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.2.2 Connection elements 11-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.2.3 Communication options 11-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3 OP170 B 11-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3.1 Dimensions and Mounting Area 11-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3.2 Connection Elements 11-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3.3 Communication Options 11-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3.4 Labeling Function Keys (OP170 B) 11-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Memory card for TP170 B and OP170 B 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Maintenance/Upkeep 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clean Screen/Keyboard 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Operating System Update 14-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Appendices A Technical Data A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B Interface Assignment B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C System Messages C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D ESD Guidelines D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E SIMATIC HMI Documentation E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . www.dienhathe.vn www.dienhathe.com

- 12. Contents x TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 www.dienhathe.vn www.dienhathe.com

- 13. 1-1 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Introduction Low-end units The Touch Panels TP170 A and TP170 B, and Operator Panel OP170 B represent products in the new series of low-end operating units. The units in this series are based on the innovative standard WindowsR CE operating system. They complete the SIMATIC HMI product range in the low-end sector. The TP170 A is a low-price initial unit which can operate with all SIMATIC S7 CPUs. The TP170 B and OP170 B fulfill all sophisticated functional requirements. This new product series enables self-created graphics, digital photos and scanned screens to be integrated in a project. Bars and trend curve diagrams can still be used to graphically display temperature progressions, for example. The units are equipped with an interface for MPI and PROFIBUS-DP. This interface is also used for downloading configurations. The unit memories are designed for small to medium-size configurations. Here is a short selection of common features: S Automatic transfer detection for downloading configurations S Password protection S Input/Output fields to display and modify process parameters S Configurable buttons and function keys (OP170 B) to control input/output and data bits S Bars for the graphical dsplay of dynamic values S Standard library for graphics and buttons can be used under ProTool CS S Graphics can be configured to label buttons or as format-filling background screens S Fixed text for labeling buttons, process screens or process values in any character size Additional features with TP170 B and OP170 B: S Print functions S Trends S Scheduler S Recipe management S Backing up recipe data and configurations on optional memory cards (CF card) A complete overview of the functional range of the units is provided Chapter 2. 1 www.dienhathe.vn www.dienhathe.com

- 14. Introduction 1-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Area of use of the units The units have been conceived for easy machine operation and monitoring. They provide a realistic graphical representation of the machine or system to be monitored. Their area of use include implementation in machine and apparatus construction as well as in the packing and electronics industry. The high degree of protection (IP65 on the front side) and non-implementation of moving storage media, such as hard disks and floppy disks, ensure the operating units are also suitable for use in rough industrial environments and directly on site on the respective machine. Installation locations for the units include: S Panels S Consoles As a result of their minimum installation depth, the units are particularly suited for operation near the machine. Easy to operate and observe The units enable operating statuses, current process values and errors concerning a connected PLC to be graphically displayed and the relevant machine or system to be easily monitored and operated. Display and operation of the units can be adapted optimally for the respective process requirements by using the configuration software ProTool CS. The units can be used to: S control and monitor the process by means of the menu system. Setpoint values or control element settings, for instance, can be modified by entering values or activating configured function keys; S display processes, machines and systems on full-graphic, dynamic screens; S display and edit messages and, for example, process tags in output fields, and to visualize bars or status display; S to intervene directly in processes via the Touch Screen (TP170 A, TP170 B) or using the integrated keyboard (OP170 B). www.dienhathe.vn www.dienhathe.com

- 15. Introduction 1-3 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Configuring using ProTool/Pro CS, ProTool and ProTool/Lite Graphics, texts and operating and display elements which need to be represented on the operating units must first be created on a configuration computer (PC or PU) using the configuration software SIMATIC ProTool/Pro CS, ProTool or ProTool/Lite. The configuration computer must be connected to the operating unit in order to download the project to the operating unit (refer to “Configuration phase” in Figure 1-1). Once the project has been successfully downloaded, connect the operating unit to the PLC. The operating unit can then communicate with the PLC and respond according to the information configured for running the program in the PLC (refer to “Process control phase” in Figure 1-1). Create project data Save project data Test project Simulate project Download project data Connected to PLC Configuration phase Process running phase PC/PU PLC TP170 A / TP170 B / OP170 B Figure 1-1 Configuration and process running phase Note The units can be configured, as required, using the configuration software ProTool/Pro CS, ProTool or ProTool/Lite. Throughout this manual, the term ProTool CS (CS: Configuration System) is used to represent all three software variants. www.dienhathe.vn www.dienhathe.com

- 16. Introduction 1-4 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Overview of units TP170 A, TP170 B OP170 B TP170 A TP170 B OP170 B Processor Type 32 bit RISC Memory Memory for configuration 256 kByte 512 kByte Software Operating system MicrosoftR WindowsR CE Ser. interface 1 Physics 1 ´ RS232 (9-pin) 1 ´ RS422/RS485 S7 connection MPI/PROFIBUS-DP Max. baud rate 1.5 MB 12 MB Ser. interface 2 – RS232 Display Active screen area (W ´ H) in mm 211 ´ 158 (6’’) Resolution (pixels) 320 ´ 240 Colors 4 Blue Mode 4 Blue Mode or 16 colors 4 Blue Mode Operating elements Touch Screen ✔ – Matrix keyboard – ✔ Function keys with configurable functions – 24 (18 with LEDs) Those usable as softkeys – 14 Labeling the function keys – System- specific with labelling strips Special features S External memory extension: -- Slot for CF card – ✔ www.dienhathe.vn www.dienhathe.com

- 17. Introduction 1-5 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Further information Detailed information on the technical data of the operating units is provided in Appendix A of this manual. Detailed descriptions of the creation of projects for the operating unit and configuration software functions are provided in the ProTool Configuring Windows-based Systems user’s guide and in the online help for ProTool CS. Connection of the operating unit to the PLC is described in the Communication for Windows-based Systems user’s manual. Any new information which could not be taken into account for printing in the guides is provided in the Readme.wri file on the ProTool CD. www.dienhathe.vn www.dienhathe.com

- 18. Introduction 1-6 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 www.dienhathe.vn www.dienhathe.com

- 19. 2-1 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Functionality The table below summarizes the functional scope of the operating units. The values specified are the maximum values which can be managed by the units. The values are limited by the size of the memory used. Function TP170 A TP170 B OP170 B Event messages Number 100 4001) Display Message view Message line, message window/ message page, message view View all queued messages Message view Message page/Message view Message length per line 70 characters Process values in message text 8 Edit messages – ✔ Alarm messages Number – 4001) Display – Message window/ message page/ message view Message line/ message window/ message page/message view Type of display – first/last, selectable View all queued messages – In message page/message view Message length per line – 70 characters Process values in message text – 8 Acknowledge individual alarm messages – ✔ Acknowledge several alarm messages simultaneously (group acknowledgement) – 16 acknowledgment groups Edit messages – ✔ 2 www.dienhathe.vn www.dienhathe.com

- 20. Functionality 2-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Function TP170 A TP170 B OP170 B ALARM_S Display S7 messages – ✔ Message logging Output to printer – ✔ Volatile message b ff Capacity – 128 message events buffer View event/alarm messages –/– ✔/✔ Delete – ✔ Print – ✔ Message events queued simultaneously (max.) 16 64 Message acquisition Time of occurrence Date/Time Message events Arrived, Departed Arrived, departed, acknowledged Screens Number 20 100 Fields per screen 20 50 Tags per screen 20 50 Complex elements per screen 5 View ✔ ✔ ✔ Print (hardcopy) – ✔ ✔ Screen objects S Graphics ✔ ✔ ✔ S Text ✔ ✔ ✔ S Output field ✔ ✔ ✔ S Input field ✔ ✔ ✔ S Symbolic output field – ✔ ✔ S Selection field – ✔ ✔ S Date/Time – ✔ ✔ S Graphics list – ✔ ✔ S Vector graphic – ✔ ✔ S Button – ✔ ✔ S Status button ✔ ✔ ✔ S Switches – ✔ ✔ S Hidden button – ✔ ✔ S Trend graphic – ✔ ✔ S Bar ✔ ✔ ✔ S Message view – ✔ ✔ www.dienhathe.vn www.dienhathe.com

- 21. Functionality 2-3 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 OP170 BTP170 BTP170 AFunction Screens Screen objects S Simple message view ✔ ✔ ✔ S Password list – ✔ ✔ S Recipe view – ✔ ✔ Operator guidance S Dynamic attributes – ✔ ✔ S Call/Hide objects – ✔ ✔ S Help text – ✔ ✔ S TAB sequence – – ✔ S Icons for softkeys – – ✔ S LEDs in function keys – – ✔ Fixed window – ✔ ✔ Limit value monitoring Inputs/outputs ✔ ✔ ✔ Conversion functions Inputs/outputs – ✔ ✔ Tags Number 100 250 Help text Lines/characters – 7/35 7/35 For messages – ✔ ✔ For screens – ✔ ✔ For screen objects S Input field – ✔ ✔ S Selection field – ✔ ✔ S Button – – ✔ S Status button – – ✔ S Switches – – ✔ S Hidden button – – ✔ Trends Number – 50 Graphic objects Number 20 50 Text elements Number 100 1000 Print functions Hardcopy of screen content – ✔ ✔ Direct message logging – ✔ ✔ Password protection Number of passwords 1 50 Password level – 10 (0..9) Recipes Number – 20 Data records per recipe – 502) Entries per recipe – 60 www.dienhathe.vn www.dienhathe.com

- 22. Functionality 2-4 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 OP170 BTP170 BTP170 AFunction Online language change Number of languages 1 3 Screen settings Contrast ✔ ✔ ✔ Scheduler Trigger functions cylically or once – ✔ ✔ Connections3) Number 1 4 Communication SIMATIC S5 S AS511 4) S PROFIBUS-DP – – ✔ ✔ ✔ ✔ SIMATIC S7/M7 S MPI ✔ ✔ ✔ S PROFIBUS-DP ✔ ✔ ✔ SIMATIC 505 S NITP S PROFIBUS-DP – – ✔ ✔ ✔ ✔ Connection to PLCs from other manufacturers Allen Bradley (PLC-5, SLC 500) S DF1 S DH+ 5) S DH485 5) – – – ✔ ✔ ✔ ✔ ✔ ✔ LG (Lucky Goldstar) S GLOFA GM ✔ ✔ ✔ Modicon S Modbus ✔ ✔ ✔ Mitsubishi FX – ✔ ✔ Telemecanique TSX S Adjust S Uni-Telway – – ✔ ✔ ✔ ✔ 1) Total number for event and alarm messages 2) Limited by storage medium 3) With SIMATIC S7 4) With adapter 5) Via external module www.dienhathe.vn www.dienhathe.com

- 23. 3-1 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Commissioning In this chapter This chapter provides information on: S starting up the operating unit for the first time (Page 3-3) S restarting the operating unit (Page 3-4) S options for download mode (Page 3-6) S testing the project on the operating unit (Page 3-10) S downloading the project back from the TP170 B and OP170 B (Page 3-12) S backup/restore the internal Flash memory using the TP170 B and OP170 B (Page 3-14) Operating the operating units in the start-up phase TP170 A: Select the required object in the Start menu (Figure 3-1) and Configuration menu (Figure 3-4) by touching the relevant button. TP170 B: Select the required object in the Start menu (Figure 3-2) and Configuration menu (Figure 3-5) by touching the relevant button. OP170 B: Proceed as follows to operate the Start menu (Figure 3-3) and Configuration menu (Figure 3-5):: Step Procedure 1 Select the object to be operated (button, check box or input field) using the Tabulator key. The object currently selected is marked by a border or a different color. 2 S Buttons/Check boxes: Press the Enter key in order to trigger the marked button or activate/deactivate the marked check box. 3 www.dienhathe.vn www.dienhathe.com

- 24. Commissioning 3-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Further information on operating the units is provided in the following chapters: S General Operation: TP170 A, TP170 B: Chapter 4 OP170 B: Chapter5 S Operating Special Screen Objects: TP170 A: Chapter 6 TP170 B, OP170 B: Chapter7 www.dienhathe.vn www.dienhathe.com

- 25. Commissioning 3-3 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 3.1 Initial Startup Procedure When the operating unit is started up for the first time, no project has been loaded on it. In order to download the necessary project data and the runtime software from the configuration computer to the operating unit, proceed as follows, observing the sequence: Step Procedure 1 Depending on the settings in the Configuration menu (Figure 3-4 or 3-5), connect the interface IF1A or IF2 (serial)1) or IF1B (MPI) of the operating unit to the configuration computer using an appropriate standard cable. 2 Switch on the power supply for the operating unit. Since no project has been loaded on the operating unit up to this point, it automatically switches to Download mode. The operating unit displays the message Connecting to host until it receives data from the configuration computer or the button Cancel is pressed. If the message Connecting to host does not appear, it is probable that the options for download mode have been incorrectly set (refer to the note on Page 3-8). 3 If data should be downloaded via an MPI connection, set the following parameters on the configuration computer: S OP address: 1 S Transmission rate: 187.5 kBaud Start downloading the project on the configuration computer. Further settings necessary on the configuration computer for the download operation are provided in the ProTool Configuring Windows-based Systems user’s guide. The configuration computer checks the connection to the operating unit. If the connection is not available or defective, the corresponding error message appears. If downloading from the configuration computer is terminated as a result of a compatibility conflict, please continue as described in Chapter 14. If the connection is correct, the project data is downloaded to the operating unit. Following successful downloading, the operating unit restarts and displays the start screen of the project that has just been loaded. 1) TP170 A: IF1A TP170 B, OP170 B: IF2 www.dienhathe.vn www.dienhathe.com

- 26. Commissioning 3-4 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 3.2 Recommissioning Purpose During recommissioning, a project already loaded on the operating unit is replaced by another. In this case, the project data is downloaded from the configuration computer to the operating unit. The following options are available to switch the operating unit to Download mode: S Start downloading manually during the operating unit start-up phase. S Start downloading automatically while the operating unit is in operation. S Start downloading via a correspondingly configured operating element while the operating unit is in operation (refer to Page 9-7). Start downloading manually during the operating unit start-up phase Step Procedure 1 Connect interface IF1A or IF2 (serial)1), or IF1B (MPI), on the operating unit to the configuration computer using an appropriate standard cable. 2 Switch on the power supply for the operating unit. 3 If necessary, check the interface settings in the Configuration menu (Figure 3-4 or 3-5) and adapt them as required. 4 During the operating unit start-up phase, the menu illustrated in Figure 3-1, 3-2 or 3-3 appears briefly. Press the Download button to set the operating unit to Download mode before the start-up routine is completed. The operating unit continues to display the message Connecting to host until it receives data from the configuration computer or the Cancel button is pressed. If the message Connecting to host does not appear, it is probable that the options for download mode have been incorrectly set (refer to the note on Page 3-8). 5 If downloading should be performed via an MPI connection, set the OP address and transmission rate valid for the operating unit on the configuration computer (refer to the note on Page 3-5). Start downloading the project on the configuration computer. The configuration computer checks the connection to the operating unit. If the connection is not available or defective, the configuration computer issues the corresponding error message. If downloading from the configuration computer is terminated as a result of a compatibility conflict, please continue as described in Chapter 14. If the connection is correct, the new project is downloaded to the operating unit. Following successful downloading, the operating unit restarts and displays the start screen of the projects that has just been loaded. 1) TP170 A: IF1A TP170 B, OP170 B: IF2 www.dienhathe.vn www.dienhathe.com

- 27. Commissioning 3-5 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Start downloading automatically when the operating unit is in operation The operating unit can be switched automatically to Download mode from normal operation as soon as downloading is started on the connected configuration computer. This option is especially recommended for the test phase of a new project because the transfer is performed without intervention on the operating unit. A condition for this is that the following settings have been defined in the Configuration (TP170 A: Figures 3-4, TP170 B and OP170 B: Figure 3-5): MPI connection: S Option MPI Transfer Enable is activated S Option MPI Transfer Remote Control is activated Serial connection: S Option Serial Transfer Enable is activated S Option Serial Transfer Remote Control is activated A detailed description of the settings possible in the Configuration menu is provided on Page 3-8. Note on MPI transfer The bus parameters (e.g. MPI address, baud rate etc.) are read out of the project currently loaded on the operating unit. Only use these parameters when downloading a new project, even if different parameters are configured for the new project because the new parameters only take effect after downloading has been completed successfully. www.dienhathe.vn www.dienhathe.com

- 28. Commissioning 3-6 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 3.3 Options for Download Mode Overview The following options can be set for download mode: S Automatic switching to download mode from normal operation when data transfer is initiated from the connected configuration computer S Download mode can be restricted to a specific connection type so that downloading can only occur either via a serial connection or an MPI connection Call in Configuration menu The options for Download mode can only be set when the operating unit is in its start-up phase. During the start-up phase, the Start menu appears briefly (TP170 A: Figure 3-1, TP170 B: Figure 3-2, OP170 B: Figure 3-3). Press the Config button to call in the Configuration menu (TP170 A: Figures 3-4, TP170 B and OP170 B: Figure 3-5). Figure 3-1 TP170 A Start menu Figure 3-2 TP170 B Start menu www.dienhathe.vn www.dienhathe.com

- 29. Commissioning 3-7 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Figure 3-3 OP170 B Start menu Information on the buttons Backup and Restore (TP170 B and OP170 B) is available in Chapter 3.6. Figure 3-4 TP170 A Configuration menu Figure 3-5 TP170 B and OP170 B Configuration menu www.dienhathe.vn www.dienhathe.com

- 30. Commissioning 3-8 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Download mode settings Setting the download options in the Configuration menu has the following effects: S Option MPI Transfer Enable: If this option is deactivated, the operating unit Download mode does not permit data transfer via an MPI connection. Activate the option to enable connection only via MPI or PROFIBUS-DP (SIMATIC S7). S Option MPI Transfer Remote Control: This option is only available if the option MPI Transfer Enable is activated. When this option is active, the operating unit automatically switches from normal operation to Download mode in the case of an MPI transfer from the configuration computer. S Option Serial Transfer Enable: If this option is deactivated, the operating unit does not permit data transfer via a serial interface (refer to the note below). S Option Serial Transfer Remote Control: This option is only available if the option Serial Transfer Enable is activated. When this option is active, the operating unit automatically switches from normal operation to Download mode in the case of a serial transfer from the configuration computer. Press the OK button to confirm the settings currently defined for the download options. The Configuration menu is closed and the Start menu appears. Press the Cancel button to close the Configuration menu and access the Start menu. Any modifications made to the settings are rejected. The group “MPI Transfer” displays both bus parameters “MPI address” and “Baud Rate”. These parameters are valid for the project currently loaded on the operating unit. ! Caution When the option Remote Control is active, ensure that the operating unit is not inadvertently switched to download mode from the configuration computer when in normal operation. Note If the options MPI Transfer Enable and Serial Transfer Enable are deactivated, it is not possible to download a project from the configuration computer to the operating unit. www.dienhathe.vn www.dienhathe.com

- 31. Commissioning 3-9 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Exit Start menu If the operating unit still has no project, it automatically switches to download mode after approx. 10 seconds after having been switched on. Press the Download button to switch the operating unit to Download mode manually. If the operating unit contains a project, it is started automatically approx. 10 seconds after being switched on. The project can be started manually by pressing the Start button. www.dienhathe.vn www.dienhathe.com

- 32. Commissioning 3-10 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 3.4 Testing a Project on the Operating Unit Conditions In order to switch the operating unit between the operating modes OFFLINE and ONLINE, the function Change_mode must be linked to an operating element in the project. Testing on the configuration computer The material supplied with ProTool contains a simulation program which can be used to test the project on the configuration computer without the necessity of connecting a PLC or operating unit. Detailed information on this is provided in the ProTool Configuring Windows-based Systems and in the online help to ProTool CS. Testing without a PLC connected (OFFLINE mode) After setting the operating unit to operating mode OFFLINE, the individual project functions can be tested without them being affected by the PLC. PLC tags are not updated in OFFLINE mode. Step Procedure 1 Switch the operating unit to operating mode OFFLINE (refer to Page 9-7). 2 Check all the configured screens in respect of correct representation. 3 Check the screen hierarchy. 4 Check the input fields. 5 Test the function keys. If faults occur when executing the individual steps, download the project again. www.dienhathe.vn www.dienhathe.com

- 33. Commissioning 3-11 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Testing with a PLC connected (ONLINE mode) When a PLC is connected, it is possible to test the communication between the operating unit and PLC in ONLINE mode. This includes checking that the correct data areas have been configured. Step Procedure 1 Connect the operating unit to the PLC. 2 Test all the items in the project for which communication with the PLC is necessary e.g.: S messages, S print functions S automatic message logging S selecting screens, etc. www.dienhathe.vn www.dienhathe.com

- 34. Commissioning 3-12 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 3.5 Download Back (TP170 B and OP170 B) Purpose During downloading, generally only the run-capable project (*.fwd) which has been generated is downloaded on the operating unit. If the original project file is to be used for further development of the project or for fault analysis, it must remain on the configuration computer. Not only the generated project can be stored on the TP170 B and OP170 B units, but also the project source file (*.pdb), so that it can be retrieved (downloaded back) from the operating unit later, if necessary. Advantage After downloading a project back, it can be analyzed and modified even if the original configuration computer cannot be accessed or the source file (*.pdb) on it for the project is no longer available. Conditions The following conditions must be fulfilled in order to retrieve the source file from the run-capable project file: S The operating unit must be equipped with a memory card. S Downloading of the current project file from the configuration computer to the operating unit must be performed using the option Download Back Enabled. What happens during download/download back? In the case of downloading including transfer of the source file, the project is compressed from the source format (*.pdb) and downloaded to the operating unit as a *.pdz file. After downloading back, the file is decompressed in the ProTool CS configuration software. The project must be given a new name on the configuration computer. Note S The downloaded back, decompressed project file (*.pdb) can only be opened with a ProTool CS whose version number is greater or equal to that of the configuration software with which the project was created. S ProTool CS cannot check whether the source file on the operating unit matches the project actually run on it. If downloading is performed at any time without the option “Download Back” being activated, it is possible that old project data is on the operating unit which no longer matches the current project. www.dienhathe.vn www.dienhathe.com

- 35. Commissioning 3-13 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Instructions Downloading a project back from the operating unit: Step Procedure 1 Select the menu option File ® Download Back in ProTool CS on the configuration computer. 2 Select one of the two following connection types between the operating unit and configuration computer in the Download Back Settings dialog: S Serial S MPI/PROFIBUS-DP (via network connection) 3 Click on Edit and set the connection parameters: S for serial: connection and baud rate S for MPI: OP address of the operating unit The settings are saved and correspondingly reapplied when downloading back is triggered at a later date. 4 Switch the operating unit to download mode manually or using Remote Control according to the setting in the Configuration menu. 5 Start downloading back with OK. Download back automatically switches the operating unit download mode. Note A condition for this is that the download type implemented is set on the operating unit (refer to Page 3-8). Following successful downloading back, the Save as dialog opens. 6 Enter a new name or select an existing project to be overwritten and click on Save. The project retrieved is saved and automatically opened in ProTool CS. www.dienhathe.vn www.dienhathe.com

- 36. Commissioning 3-14 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 3.6 Backup/Restore the Internal Flash Memory (TP170 B and OP170 B) Purpose The functions Backup and Restore provide the following options: S Creating a backup copy of the entire project on memory card, S Recovering a stored project in the case of a fault, S Updating a project regardless of where the operating unit is in use, without a configuration computer. Conditions The two functions, Backup and Restore, are only available in the Start menu (TP170 B: Figure 3-2, OP170 B: Figure 3-3) during the operating unit’s start-up phase. In order to access the Start menu, either the Exit_runtime function must be called in or the unit restarted. Insert the memory card in the expansion slot before starting the Backup/Restore process. Notes on memory cards are provided in Chapter 12. Backup During a backup, the entire content of the internal Flash memory is copied onto an external storage medium. Both system data and configuration data are copied. This data is stored under Storage Card/pdz. www.dienhathe.vn www.dienhathe.com

- 37. Commissioning 3-15 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Proceed as follows to create a backup copy of the internal Flash memory: Step Procedure 1 Deactivate the write protection on the memory card, if set. 2 Insert the memory card in the slot (TP170 B: Figure 11-4 on Page 11-6, OP170 B: Figure 11-6 on Page 11-9). 3 Call in the operating unit Start menu (TP170 B: Figure 3-2, OP170 B: Figure 3-3). 4 Start the Backup process by using the Backup button. 5 Confirm the deletion of any existing backup files beforehand. 6 When the data has been completely downloaded, the operating unit issues a message. 7 Remove the memory card from the operating unit. 8 Activate the write protection on the memory card, if available. Restore In the case of a restore process, the content of a Flash memory stored on an external storage medium is reloaded into the internal Flash memory. Both system data and configuration data are copied. Prior to this, the operating unit Flash memory is completely cleared following confirmation. Proceed as follows to restore the content of the internal Flash memory: Step Procedure 1 Activate the write protection on the memory card, if available. 2 Insert the memory card in the slot (TP170 B: Figure 11-4 on Page 11-6, OP170 B: Figure 11-6 on Page 11-9). 3 Call in the operating unit Start menu (TP170 B: Figure 3-2, OP170 B: Figure 3-3). 4 Start the restore process by clicking on the Restore button. 5 Before starting the Restore process, the operating unit checks the compatibility with the data to be restored. In the case of incompatibility, the operating unit terminates the process and issues the relevant message. 6 Confirm that the internal Flash memory. 7 When the data has been completely downloaded, the operating unit issues a message. 8 Remove the memory card from the operating unit. 9 Start up the operating unit again. www.dienhathe.vn www.dienhathe.com

- 38. Commissioning 3-16 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 www.dienhathe.vn www.dienhathe.com

- 39. 4-1 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Operating Touch Panels TP170 A and TP170 B Operating concept The screen is used to observe the operating status of the machine or system being monitored and, at the same time, to intervene directly in the process running simply by touching the buttons and input fields displayed. 4.1 Operating Touch Elements Definition Touch elements are contact-sensitive operating elements provided on the touch panel screen, such as buttons, input fields and message windows. Their operation is basically no different from pressing conventional keys. Touch elements are operated by touching them lightly with your finger or a suitable object. Note Never use pointed or sharp instruments to operate the Touch Panel to prevent damage to the plastic surface of the touch screen. ! Caution Be sure to touch only one point on the touch panel screen element. Never touch more than one touch element at a time. Otherwise, an action may be unintentionally initiated. 4 www.dienhathe.vn www.dienhathe.com

- 40. Operating Touch Panels TP170 A and TP170 B 4-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Operation acknowledgement As soon as the touch panel detects valid contact with a touch element, it responds by displaying a visual acknowledgement. An acknowledgment is independent of communication with the PLC. It is not an indication of the required action actually having been executed. The type of visual acknowledgement is dependent on the operating element touched: S Buttons In the case of 3D-effect configurations, visual representation is distinguished according to the statuses touched and untouched. Examples of representation are illustrated below by means of the Status button: UntouchedTouched S Input fields After an input field has been touched, the screen keyboard illustrated in Figure 4-1 appears as acknowledgement of the operation. www.dienhathe.vn www.dienhathe.com

- 41. Operating Touch Panels TP170 A and TP170 B 4-3 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 4.1.1 Enter Numeric Values Principles of operation In order to enter numeric values, the touch panel automatically displays a numeric screen keyboard after touching an input field, for example. Keys on the keyboard which are available for operation are highlighted as 3D keys, those not available are simply displayed as areas. After completing the input, the screen keyboard is automatically hidden. Figure 4-1 illustrates an example of the screen keyboard for entering numeric values. The keys A to F for entering hexadecimal values are inoperable in this example. The Help key (TP170 B) is only displayed when help text has been configured for that particular input field. Figure 4-1 Screen keyboard for numeric values www.dienhathe.vn www.dienhathe.com

- 42. Operating Touch Panels TP170 A and TP170 B 4-4 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Meanings of buttons Table 4-1 Significance of buttons Button Function Purpose ...0 Enter character Enter character via the keyboard in normal or Shift level. Move input position to the left Move current input position one character to the left. Move input position to the right Move current input position one character to the right. Cancel (Escape) Discard input and close the screen keyboard. Enter Confirm input and close the screen keyboard. Call in help text Calls in the configured help text. Backspace Deletes the character to the left of the current cursor position. Procedure Numeric values are entered character by character using the input keys on the screen keyboard. If a value already exists in the field, this is deleted on entering the first character. After beginning entering a value, it is impossible to exit from the field without either confirming the entry or canceling it. Characters entered are aligned to the right. On entering a new character, all those already entered are shifted one position to the left (pocket calculator format). Invalid characters are rejected and an error message appears. On exceeding the maximum number of characters, the last character entered is overwritten. Confirm the value entered by pressing ENTER or cancel the input by pressing ESC. The window is closed in both cases. www.dienhathe.vn www.dienhathe.com

- 43. Operating Touch Panels TP170 A and TP170 B 4-5 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Limit value test Limit values can be configured for numeric input fields. In this case, values entered are only accepted when they lie within the limits configured. If an attempt is made to enter a value which is outside the configured limits, it is rejected and the original value automatically reinserted. 4.1.2 Enter Alphanumeric Values Principles of operation In order to enter alphanumeric values, the touch panel automatically displays an alphanumeric screen keyboard after touching an input field. Keys on the keyboard which are available for operation are highlighted as 3D keys, those not available are simply displayed as areas. After completing the input, the screen keyboard is automatically hidden. Figure 4-2 illustrates an example of a normal screen keyboard to enter alphanumeric values. The Help key (TP170 B) is only displayed when help text has been configured for that particular input field. Figure 4-2 Screen keyboard for alphanumeric values, normal level Table 4-1 on Page 4-4 explains the significance of the individual keys. www.dienhathe.vn www.dienhathe.com

- 44. Operating Touch Panels TP170 A and TP170 B 4-6 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Keyboard levels The alphanumeric screen keyboard has two levels: S Normal level S Shift level Toggle between the two levels by pressing the SHIFT key. Figure 4-3 Screen keyboard for alphanumeric values, Shift level Procedure Characters entered are aligned to the left. Following each entry, the cursor skips to the right to the next entry position. If an alphanumeric input field already contains a value, it is displayed in reversed colors and deleted as the new value is entered. In order to edit an existing value, press one of the cursor keys as the first entry. On pressing CURSOR LEFT, the cursor remains on the first character, after pressing CURSOR RIGHT it skips to the second character. In this case, the value reverts back to its normal representation and can be edited. On exceeding the maximum number of characters, the last character entered is overwritten. www.dienhathe.vn www.dienhathe.com

- 45. Operating Touch Panels TP170 A and TP170 B 4-7 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Confirm the value entered by pressing ENTER or cancel the input by pressing ESC. The window is closed in both cases. The current input position is displayed in inverse colors. Invalid characters (e.g. values greater than 23 when specifying the time for a clock) are rejected and an error message appears. On exceeding the maximum number of characters which can be entered, the last character entered is overwritten. Note The characters available and layout of the alphanumeric screen keyboard are independent of the language set on the operating unit. 4.1.3 Enter Symbolic Values on the TP170 B Purpose Values entered in a symbolic input field are not entered character-by-character but are selected from a list provided, e.g.: Figure 4-4 Symbolic input field, opened (example) Procedure Touch the symbolic input field on the operating unit touch screen. In this case, the selection list opens up immediately. After selecting an element from the list, the selection list is closed and the selected text appears in the list box. www.dienhathe.vn www.dienhathe.com

- 46. Operating Touch Panels TP170 A and TP170 B 4-8 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 4.2 Calling in Help Text on the TP170 B Purpose Configuration planners can provide users with additional information on messages, screens and input fields in the form of help texts. Help text, concerning an input field for example, may provide information on permissible value ranges (refer to Figure 4-5) or, in the case of an alarm message, information related to the cause and its elimination. Enter temperature setpoint for Tank_1 (Range 40...80 _C) Figure 4-5 Help text for an input field (example) Procedure S Call in help on messages Touch the following key in the message window, on the message page, in the message buffer or the message view S Call in help on input fields Touch the Help key on the screen keyboard. This key only appears if a configured help text exists. S Call in help to screen If the function Display Information Text has been assigned to a button, for example, in the project, touch that button to call in the help text configured for the current screen. www.dienhathe.vn www.dienhathe.com

- 47. 5-1 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Operating Keyboard Unit OP170 B Operating concept The operating status of the machine or system to be monitored can be observed on the OP170 B screen and the process currently running directly influenced by using the keyboard. This chapter provides information on the general operating procedures for the OP170 B. Information regarding operation for special screen objects is provided in Chapter 6. 5.1 Integrated Keyboard Keypads The OP170 B keyboard consists of two functional keypads (Figure 5-1): S Function keys/Soft keys (keys K1 to K10 and F1 to F14) S System keys Figure 5-1 Assignment of OP170 B keypads 5 www.dienhathe.vn www.dienhathe.com

- 48. Operating Keyboard Unit OP170 B 5-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Function keys for global function assignment A function key for global function assignment always triggers the same action on the OP170 B or in the PLC regardless of the screen currently open (global significance on the OP170 B). These actions could include: S Open screen S Display current alarm messages S Print screen (hardcopy) The following function keys can be assigned during configuration: K1 to K10 F1 to F14 Function keys for local function assignment (softkeys) A function key for local function assignment (softkey) can trigger different actions on the OP170 B or in the PLC according to the screen currently open (local significance of current screen). If configured, the function of a softkey is indicated by an icon located at the edge of the current screen. All the function keys located directly at the edge of the screen can be assigned locally significant functions during configuration. In the case of the OP170 B, this relates to the keys F1 to F14. Note If a function key is pressed directly following changing screens, the corresponding function associated with the new screen is triggered before the screen is generated. www.dienhathe.vn www.dienhathe.com

- 49. Operating Keyboard Unit OP170 B 5-3 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 System keys Table 5-1 Functions of the system keys Key Function Purpose Shift Switches the assignment of the input keys from numeric to alphanumeric input. S No LED lights up: Numeric assignment is active. Press the key once to switch to alphanumeric assignment. S An LED lights up: The left or right alphanumeric assignment is active. Each time the key is pressed switches through left, right and off. Activate editing mode, Insert/Delete character S Activates editing mode. S Deletes or inserts individual characters. Delete character in numeric keyboard assignment. To insert characters, use the Shift key to switch to alphanumeric assignment. Cancel S Deletes the character of a value entered and resets the original value. S Closes the active window. Acknowledge Acknowledges the currently displayed alarm message or all messages in an acknowledgment group (group acknowledgement). The LED lights up as long as unacknowledged alarm messages are queued. Display help text Opens a window with help text in respect of the selected object (message, input field). The LED indicates if help text exists for the selected object. Acknowledge S Accepts and ends the input. S Opens a selection field for symbolic input. S Triggers the function on the selected button. Tabulator Moves to the next screen object available for selection in the configured tabulation sequence. Delete character Deletes the character to the left of the cursor. Move cursor S Move to the next screen object available for selection to the right, left, above or below the current screen object. S Navigation in the screen object. www.dienhathe.vn www.dienhathe.com

- 50. Operating Keyboard Unit OP170 B 5-4 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Table 5-1 Functions of the system keys, continued PurposeFunctionKey Only use in combination with other keys, e.g. navigation in trend view (Page 7-26). Only use in combination with other keys, e.g. shift to capital letters. Only for use with key combinations, e.g. open selection field (Page 5-5). Scroll one page back . Scroll one page forward. www.dienhathe.vn www.dienhathe.com

- 51. Operating Keyboard Unit OP170 B 5-5 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 5.2 Key Combinations General operation Table 5-2 Key combinations Key combination Function Navigation Moves to the previous screen object available for selection in the configured tabulation sequence. Positions the cursor within a screen object, e.g. in an input field. Skip to the start, e.g. of a selection list. Skip to the end, e.g. of a selection list. Opens a selection field. Screen settings Increase the screen contrast. Reduce the screen contrast. During the start-up phase Switches the OP170 B to download mode. As long as no data transfer is taking place, it is possible to exit from download mode. Other functions Accepts the selected value in the selection field without closing it. S Changes the active window. S Switches between basic area and window. Mark all Display the properties of the marked element www.dienhathe.vn www.dienhathe.com

- 52. Operating Keyboard Unit OP170 B 5-6 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Table 5-2 Key combinations, continued FunctionKey combination Continue to next field Return to previous field Open next tab control 1) Open previous tab control 1) Close dialog without saving 1) When the name of the tab control has the focus. Operating screen objects using function keys Screen objects assigned to buttons, e.g. message view, trend view or recipe view, can also operated by means of function keys or softkeys. A condition for this is that each relevant function has been linked to a function key or softkey in the project. These functions are complied in ProTool CS within the Keyboard action for screen objects. www.dienhathe.vn www.dienhathe.com

- 53. Operating Keyboard Unit OP170 B 5-7 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 5.3 Entering Values Marking On selecting an input field, the entire field content is marked by changing color. After pressing a key (except a cursor key), the field content is deleted and the new input displayed. After selecting a field, press the SHIFT key and a cursor key simultaneously to clear the marking on the field contents and enable the cursor to be moved freely within the field. Operation Proceed as follows in order to enter values in an input field: Step Procedure 1 Use the cursor keys to position the cursor on the desired input field. 2 Enter the value in the following form, according to the configuration: S Numeric (Page 5-8) S Alphanumeric (Page 5-9) S Symbolic (Page 5-10) 3 Confirm the entry. www.dienhathe.vn www.dienhathe.com

- 54. Operating Keyboard Unit OP170 B 5-8 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 5.3.1 Enter Numeric Values Procedure Numeric values are entered character-by-character using the input keys on the keyboard. If a value already exists in the field, this is deleted on entering the first character. After beginning entering a value, it is impossible to exit from the field without either confirming the entry or canceling it. Possible values The following values are possible in numeric input fields: Values Keys Description Decimal ... The input keys are numerically assigned. ... , Hexadecimal ... ... To enter the characters A ...F use the Shift key to switch to alphanumeric assignment. Digits , The input keys are numerically assigned. Limit value check Limit values can be configured for numeric input fields. In this case, values entered are only accepted when they lie within the limits configured. If a value is entered which lies outside the limits, the corresponding system message appears. After they are cancelled, the original values are automatically reset. www.dienhathe.vn www.dienhathe.com

- 55. Operating Keyboard Unit OP170 B 5-9 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 5.3.2 Enter Alphanumeric Values Procedure Alphanumeric values are entered character-by-character using the input keys on the keyboard. Digits, letters and spaces are possible. After entering a character, the cursor moves one space to the right. If the entry exceeds beyond the maximum number of places, the OP170 B overwrites the last character entered with each subsequent entry. Input Keys Description Digits ... , The numeric assignment is active when no LED is on. Letters ... The alphanumeric assignment is active when one of the two LEDs is on. www.dienhathe.vn www.dienhathe.com

- 56. Operating Keyboard Unit OP170 B 5-10 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 5.3.3 Enter Symbolic Values Purpose Values entered in a symbolic input field are not entered character-by-character but are selected from a list provided, e.g.: Figure 5-2 Symbolic input field, opened (example) Procedure Step Keys Description 1 Select (e g ) Symbolic input field is marked.1 Select symbolic (e.g.) Symbolic input field is marked. y input field 2 Open symbolic input field The selection list opens up. 3 Select entry Moves cursor line by line. 4 Apply selection The value assigned to the selection becomes valid. The symbolic input field is closed. or Cancel selection The original value is reapplied. The symbolic input field is closed. Tip After pressing an alphanumeric key, the first list entry which begins with that character is selected. www.dienhathe.vn www.dienhathe.com

- 57. Operating Keyboard Unit OP170 B 5-11 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 5.4 Call Help Text Purpose Help texts consist of additional information and operating instructions provided by the configuration planner concerning messages, screens and operable screen objects. Help text, concerning an input field for example, may provide information on permissible value ranges (refer to Figure 5-3) or, in the case of an alarm message, information related to the cause and its elimination. Enter temperature setpoint for Tank_1 (Range 40...80 _C) Figure 5-3 Help text for an input field (example) Procedure Proceed as follows in order to call in the configured help text, e.g. for an input field: Step Procedure 1 Select the required input field, e.g. using the Tabulator key. 2 The LED in the HELP key lights up, indicating that a help text is available. Press the HELP key. 3 The help text configured for the input field is displayed on the OP170 B in the language set. If a help text has also been configured for the current screen, it is displayed too. 4 Press the ESC key to close the help text window. www.dienhathe.vn www.dienhathe.com

- 58. Operating Keyboard Unit OP170 B 5-12 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 www.dienhathe.vn www.dienhathe.com

- 59. 6-1 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 Screen Objects for TP170 A In this chapter This chapter introduces the screen objects which may be contained in a configuration and explains their operation. It provides the following information: S General operation (Page 6-2) S Summary of screen objects (Page 6-4) S Input field for date/time (Page 6-5) S Input field for confidential password entry (Page 6-5) S Status button (Page 6-6 S Messages (Page 6-7) S Bars (Page 6-9) 6 www.dienhathe.vn www.dienhathe.com

- 60. Screen Objects for TP170 A 6-2 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 6.1 General Operation In this chapter This chapter contains information on how to operate screens and logging in and out of the operating unit. 6.1.1 Operating Screens What is a screen? Screens visualize the progress of processes and display specified process values. A screen contains logically related process data which the operating unit can both display and modify by operating the individual values. Screen partitions A screen is basically composed of static and dynamic sections. The terms “static” and “dynamic” do not refer to the possibility of dynamically positioning screen partitions but to the connection to the PLC. Static partitions, e.g. text and graphics, are not updated by the PLC. Dynamic partitions, e.g. input and output fields, trend view and bars, are linked to the PLC and display current values constantly read in from the PLC memory. Their connection to the PLC is established by means of tags. A summary of all the screen objects which the operating unit may contain is provided on Page 6-4. Select screen There are several ways in which to select a screen: S Button Pressing a button opens the corresponding screen defined in the configuration. S Input field Enter the corresponding number of the screen to be viewed in the input field. www.dienhathe.vn www.dienhathe.com

- 61. Screen Objects for TP170 A 6-3 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 6.1.2 Logging On and Off from the Operating Unit Purpose During the configuration, input fields and buttons can be protected against unauthorized operation by assigning passwords. Important parameters and settings can then only be modified by authorized personnel. The password is defined at the moment the element is configured and cannot be modified via the operating unit. Login If operating elements are to be assigned password protection in the configuration, it must be possible for the operator to log in. In this case, the function Login_user must be linked with an operating element, preferably an input field, in the configuration. In order to access a password protected operating element during runtime, it is necessary to log in on the operating unit. It is then possible to access all password protected operating elements up to the point of logging off from the operating unit. When correspondingly configured, it is also possible to log on via an input field for confidential password entry. The character string entered is represented by placeholders (*). Logoff In order to rule out operation by unauthorized personnel, the login should not remain active on the operating unit for too long a period of time. The following options are available with which to log off from the operating unit: S Configured logout time expires If the operating unit is not operated by the user within the configured period (logout time), he is automatically logged off from the operating unit. S Log out of the operating unit If the configuration links the function Logoff_user with an operating element, the element can be used to log off from the operating unit. Tip It is possible to log off by entering an incorrect password. www.dienhathe.vn www.dienhathe.com

- 62. Screen Objects for TP170 A 6-4 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 6.2 Overview of Screen Objects Table 6-1 provides a summary of the various screen objects which a TP170 A project may contain. Table 6-1 Screen objects configurable for the TP170 A Screen object Use/Description Text Text is used during configuration to label operating and display elements, for example. Text can be configured over several lines and cannot be altered on the operating unit. Graphics Graphics can be used in the configuration, e.g. to represent a system or as an illustrative symbol for configured display and operating elements. Output field The output field displays the current value in numeric or alphanumeric form. Input field Enter a value in the input field. The values can be in numeric or alphanumeric form. Entries which lie outside the specified value range are rejected according to the limit values which have been configured. The input can be protected by means of a password. Status button A Status button is a display and operating element which has one of two states: Touched and Untouched. The states can be indicated by means of text or graphics. The Status button can be configured to be locking (switch function) or non-locking (keying function). Bar Bar graphs present a value in the form of a rectangular area. The operating unit thus provides a clear indication of how far the current value is from the limit values, or if a setpoint value has been reached, at a glance. Bars are often used to represent fill levels or workpiece numbers. Direction, scaling and labeling the axis can be configured as required. In order to identify limit values, limit value lines can be called in. Simple message view Special filter criteria for displaying pending messages are configured in the message view. Notes on operation are provided on Page 6-8. www.dienhathe.vn www.dienhathe.com

- 63. Screen Objects for TP170 A 6-5 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 6.3 Input Field for Date/Time Purpose The input field for date and time serves to enter calendar dates and the time. The input format is dependent on the language currently set on the operating unit. The figure below illustrates examples of input fields for date and time in English language format. 6.4 Input Field for Confidential Password Entry Purpose When a password is entered in the input field for confidential passwords, the characters are represented by placeholders (*). The figure below illustrates an example. www.dienhathe.vn www.dienhathe.com

- 64. Screen Objects for TP170 A 6-6 TP170 A, TP 170 B, OP170 B Equipment Manual Release 07/00 6.5 Status Button Purpose The Status button is an operating and display element with the two states Pressed and Released. Status buttons indicate the status of a unit which cannot be determined from the operating unit (e.g. a motor). At the same time, it is also possible to change the status of the unit concerned on the operating unit. Behavior The behavior of the Status button can be configured: S Switch: The switch has two stable states. It toggles from one state to the other each time it is operated, and remains in the respective state until it is operated again. S Key: The button has a fixed, stable home position. When operated, it switches to the status pressed and remains in this state as long as it is kept pressed. When released, it automatically switches back to its released position. Functions which have been assigned to the Status button can be triggered, for example, by the following configurable events: S Status change S Printing S Releasing If the status of a switch type Status button changes as a result of a modification of configured tags, not through operation, the corresponding function is not executed. Display The two indicator statuses of the types Switch and Button with acknowledgement can be assigned different texts or graphics in /Pro CS which are displayed on the Status button during runtime. Figure 6-1 illustrates an example of a switch type Status button when pressed (left) and not pressed (right). Figure 6-1 The two statuses relate to the Status button when the Switch option is set Operation Touch the Status button on the operating unit. www.dienhathe.vn www.dienhathe.com