BATCH 03 FINAL.pptx

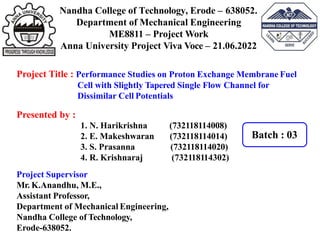

- 1. (732118114008) (732118114014) (732118114020) (732118114302) 1. N. Harikrishna 2. E. Makeshwaran 3. S. Prasanna 4. R. Krishnaraj Project Supervisor Mr. K.Anandhu, M.E., Assistant Professor, Department of Mechanical Engineering, Nandha College of Technology, Erode-638052. Nandha College of Technology, Erode – 638052. Department of Mechanical Engineering ME8811 – Project Work Anna University Project Viva Voce – 21.06.2022 Project Title : Performance Studies on Proton Exchange Membrane Fuel Cell with Slightly Tapered Single Flow Channel for Dissimilar Cell Potentials Presented by : Batch : 03

- 2. Objectives Investigate the effects of geometrical changes on single flow channel Proton Exchange Membrane Fuel Cell for its performance improvement.

- 3. Abstract • The flow channels are used for uniform reactant distribution throughout the active area of fuel cell. • This paper numerically investigates the effects of slight taper in single flow channel of PEMFC for different cell voltages (0.2 V to 0.9V). • The numerical model of straight flow channel and three different slightly tapered (0.25 mm, 0.5 mm and 0.75 mm) single flow channel PEM fuel cell was developed by using a commercial modeling package and analyzed by using COMSOL Multiphysics softwarepackage. • Different taper values and cell potentials were taken to optimize the performance of the PEMFC.

- 4. • The numerical results revealed that the PEMFC with taper flow channel at an operating voltage of 0.35 V show evidence of the better performance compared with straight flow channel. • Performance and polarization curves were drawn from the numerical results. • The current densities, power densities, anode Hydrogen concentration, cathode Oxygen concentration, anode water concentration and cathode water concentration of straight and three different slightly tapered flow channels of PEMFC with fifteen different cell potentials were compared with eachother.

- 5. Literature Survey Sl. No. Name of the Author(s) Journal Name Title of the Journal Year Findings 01 M.Muthukumar P.Karthikeyan V.Lakshminarayanan A.P.Senthil Kumar M.Vairavel R.Girimurugan Applied Mechanics and Materials Performance Studies on PEM Fuel Cell with 2, 3 and 4 Pass Serpentine Flow Field Designs 2014 The geometrical and flow parameters are governing the performance of the PEMFC. 02 P.Karthikeyan R.J.Vasanth M.Muthukumar International Journal of Hydrogen Energy Experimental Investigation on Uniform and Zigzag Positioned Porous Inserts on the Rib Surface of Cathode Flow Channel for Performance Enhancement in PEMFC 2015 The designs of flow channels are highly influencing the performance of PEMFC

- 6. Sl. No. Name of the Author(s) Journal Name Title of the Journal Year Findings 03 R.Girimurugan S.Manoj Pravin S.P.Aravinth M.Aravinthsamy P.Gowthaman International Journal of Innovative Research and Creative Technology Performance Analysis of High Temperature PEM Fuel Cell with Single Flow Channel Configuration 2015 PEMFC with an operating temperature of 453 K at an operating voltage of 0.4 V gives the better performance. 04 T.Krishnamoorthi R.Girimurugan M.Vairavel A Numerical Analysis Effects of Cathode Oxygen Concentration for Various Cell Potentials in a Six Pass Serpentine Flow Field Proton Exchange Membrane Fuel Cell 2019 The most excellent cathode Oxygen concentration is found at a cell voltage of 0.85V.

- 7. Sl. No. Name of the Author(s) Journal Name Title of the Journal Year Findings 05 S.Mayakannan V.Rajesh V.Jeeva Bharathi M.Muthuraj R.Girimurugan International Journal of Advance Research and Innovative Ideas in Education Performance Studies on 25×25 cm2 ReactiveArea Serpentine Flow Field Proton Exchange Membrane Fuel Cell with Different Cell Potentials 2015 Better current density as well as power density has achieved at a cell potential of 0.4 V.

- 8. Sl. No. Name of the Author(s) Journal Name Title of the Journal Year Findings 06 R.Girimurugan R.Kishorkumar E.Manoj D.Gowsal P.Jayaprakash International Journal of Innovative Research and Creative Technology. Performance Analysis of PEM Fuel Cell with Six Pass Serpentine Flow Field under Various Operating Voltages 2015 Operating voltage of 0.35 V gives better performance parameters 07 Dr.R.Rajappan G.Gurunathan P.Paramadhayalan S.Purushothaman R.Girimurugan International Journal of Scientific Research in Science and Technology. Effect of Cell Potentials on Gas Diffusion Layer Velocity with Serpentine Flow Channel in PEM Fuel Cell 2016 Reactant gases distribution at GDL is enhanced with increased cell potentials

- 9. Problem Identification The following problems were identified through the past literature review. • Water accumulation on anode and cathode side. • Membrane thickness • Flow channel geometry • Operating parameters.

- 10. Possible Solutions for Identified Problem(s) The following possible solutions were identified to overcome the existing problems in the single flow channel. • Modifications on Flow Channel Geometry • Changing of Membrane Material and Geometry

- 11. Methodology Study of Recent Literature Related to PEM Fuel Cell Performence Collection of issues/problems/drawbacks related to Existing PEM Fuel Cell Performence Selection of suitable solutions/methods to improve the PEM Fuel Cell Performence Feasibility Study Selection of flow channel Geometries and its Cell Potential, Power Density and Current Density of PEM Fuel Cell Performence

- 12. Methodology Commercial Modelling was Employed to Create the Entire Single Flow Channel PEM Fuel Cell In COSMOL Multiphysics Software,Equivalent Modules were Chosento Undergo the Necessary Analysis on the Successful Modelled PEMFC Assembly. Interpretation of COSMOL Multiphysics Software Analysis andResults Comparison of COSMOL Multiphysics Software Analysis andResults

- 13. Design Straight Flow Channel PEMFC 0.5 mm Taper Flow Channel PEMFC 0.25 mm Taper Flow Channel PEMFC 0.75 mm Taper Flow Channel PEMFC

- 14. Design Parameters Length (mm) Width (mm) Height (mm) Stright Flow Channel 20 1 1 0.25 mm Tapper Flow Channel 20 1 0.75 0.50 mm Tapper Flow Channel 20 1 0.5 0.75 mm Tapper Flow Channel 20 1 0.25 Parameters Dimensions (mm) Rib width 0.9 Gas Diffusion Layer Width 0.4 Membrane Thickness 0.01 Catalyst Layer Thickness 0.05

- 15. Analysis Parameters GDL porosity GDLpermeability GDL electric conductivity Gas mass fraction at anode Cathode inlet H2O mass fraction : 0.4 : 1.18×10-11m2 : 222 S/m : 0.743 : 0.023 Cathode inlet oxygen mass fraction : 0.228 Anode inlet flow velocity Cathode inlet flow velocity Anode viscosity Cathode viscosity Hydrogen molar mass Nitrogen molar mass Water molar mass Oxygen molar mass Cell temperature Pressure Cell voltages Oxygen reference concentration Hydrogen reference concentration : 0.2 m/s : 0.5 m/s : 1.19×10-5 Pa.s : 2.46×10-5Pa.s : 0.002 kg/mol : 0.028 kg/mol : 0.018 kg/mol : 0.032 kg/mol : 323 K : 101×103 Pa : 0.20 V to 0.90V : 40.88 mol/m3 : 40.88 mol/m3

- 16. Results and Discussions Concentration of Hydrogen at Anode Side of the Fuel Cell for Straight Flow Channel at Cell Voltage 0.4 V Concentration of Oxygen at Cathode Side of the Fuel Cell for Straight Flow Channel at Cell Voltage 0.4 V Minimum = 35.545 mol/m3 Maximum = 36.2 mol/m3 Minimum = 1.5019 mol/m3 Maximum = 7.6203 mol/m3

- 17. Minimum = 1.3913 mol/m3 Maximum = 2.0458 mol/m3 Minimum = 3.3466 mol/m3 Maximum = 12.346 mol/m3 Water Concentration at Anode Side of the Fuel Cell for Straight Flow Channel at Cell Voltage 0.4 V Cathode Water Concentration at Cathode Side of the Fuel Cell for Straight Flow Channel at Cell Voltage 0.35 V

- 18. Minimum = 36.195 mol/m3 Maximum = 36.201 mol/m3 Minimum = 7.5475 mol/m3 Maximum = 7.6207 mol/m3 Concentration of Hydrogen at Anode Side of the Fuel Cell for 0.25 mmTaper Flow Channel at Cell Voltage 0.85 V Concentration of Oxygen at Cathode Side of the Fuel Cell for 0.25 mmTaper Flow Channel at Cell Voltage 0.85 V

- 19. Minimum = 1.3913 mol/m3 Maximum = 1.3965 mol/m3 Minimum = 1.3667 mol/m3 Maximum = 1.4034 mol/m3 Water Concentration of at Anode Side for 0.25 mm Taper Flow Channel at Cell Voltage 0.85 V Cathode Side Water Concentration for 0.25 mm Taper Flow Channel at Cell Voltage 0.9 V

- 20. Minimum = 38.533 A/m2 Maximum = 38.931A/m2 Minimum = 35.655 mol/m3 Maximum = 35.202 mol/m3 Membrane Current Density for 0.25 mm Tapper Flow Channel PEMFC at Cell Voltage 0.9 V Concentration of Hydrogen at Anode Side of the Fuel Cell for 0.5 mmTaper Flow Channel at Cell Voltage 0.4V

- 21. Minimum = 2.4086 mol/m3 Maximum = 7.6226 mol/m3 Minimum = 1.3913 mol/m3 Maximum = 1.9369 mol/m3 Concentration of Oxygen at Cathode Side of the PEMFC For 0.5 mm Taper Flow Channel at Cell Voltage 0.4 V Water Concentration at Anode Side for 0.5 mm Taper Flow Channel for Cell Voltage 0.85 V

- 22. Minimum = 1.367 mol/m3 Maximum = 9.7232 mol/m3 Minimum = 9131.8A/m2 Maximum = 10507A/m2 Cathode Side Water Concentration for 0.5 mm Taper Flow Channel at Cell Voltage 0.4 V Membrane Current Density for 0.5 mm Tapper Flow Channel PEMFC at Cell Voltage 0.4 V

- 23. Minimum = 35.645 mol/m3 Maximum = 36.201 mol/m3 Minimum = 2.3181 mol/m3 Maximum = 7.6207 mol/m3 Concentration of Hydrogen at Anode Side of the Fuel Cell for 0.75 mm Taper Flow Channel at Cell Voltage 0.4v Concentration of Oxygen at Cathode Side of the PEMFC for 0.75 Mm Taper Flow Channel at Cell Voltage 0.4 V

- 24. Minimum = 1.3913 mol/m3 Maximum = 1.9457 mol/m3 Minimum = 1.3667 mol/m3 Maximum = 9.8646 mol/m3 Water Concentration at Anode Side for 0.75 mm Taper Flow Channel for Cell Voltage 0.4 V Water Concentration of atAnode Side for 0.75 mm Taper Flow Channel for Cell Voltage 0.4 V

- 25. Maximum and Minimum Concentration of Hydrogen Gas atAnode Side for Different Flow Channel Design Configurations Maximum and Minimum Concentration of Oxygen Gas at Cathode Side for Different Flow Channel Design Configurations

- 26. Maximum and Minimum Concentration of Water at Anode Sidefor Different Flow Channel Design Configurations Maximum and Minimum Concentration of Water at Cathode Side for Different Flow Channel Design Configurations

- 27. Polarization Curves for 0 mm, 0.25 mm, 0.5 mm And 0.75 mm Taper Flow Channel PEMFC Maximum Current Density 0.25 mm Taper Flow Channel 2.34936 A/cm2 Minimum Current Density Straight Line Flow Channel 1.56624 A/cm2

- 28. Performance Curves for 0 mm, 0.25 mm, 0.5 mm And 0.75mm Taper Flow Channel PEMFC Maximum Power Density 0.25 mm Taper Flow Channel 0.59310 W/cm2 Minimum Power Density Straight Line Flow Channel 0.39540 W/cm2

- 29. Conclusions • The performance studies on single flow channel Proton Exchange Membrane Fuel Cell (PEMFC) with 0 , 0.25, 0.50 and 0.75 mm taper channel geometries under the different cell potentials (0.20 V to 0.90 V) was successfully conceded by using the COMSOL Multiphysicssoftware. • It is concluded that, single flow channel PEM fuel cell with 0.25 mm taper having a greater current and power density of 2.34936 A/cm2 and 0.59310 W/cm2 for the cell potential of 0.20 V and 0.35 V respectively and 0.25 mm taper flow channel PEM fuel cell exhibits the better performance than other three flow channel geometries. • It is also concluded that the changes made in flow channel geometry having greater influence on the performance of the single flow channel PEM fuelcell.

- 30. References 1. M.Muthukumar, P.Karthikeyan, V.Lakshminarayanan, A.P.Senthil Kumar, M.Vairavel, R.Girimurugan, Performance Studies on PEM Fuel Cell with 2, 3 and 4 Pass Serpentine Flow Field Designs, Applied Mechanics and Materials, 2014, 592-594, pp.1728-1732. 2. P.Karthikeyan, R.J.Vasanth, M.Muthukumar, Experimental Investigation on Uniform and Zigzag Positioned Porous Inserts on the Rib Surface of Cathode Flow Channel for Performance Enhancement in PEMFC, International Journal of Hydrogen Energy, 2015, 40, pp. 4641 – 4648. 3. R.Girimurugan, S.Bharathkumar, V.Dinesh, G.Dinesh, P.Gowtham, Effect of Reactant Gases Velocity Distribution in Single Flow Channel High Temperature PEM Fuel Cell, International Journal of Innovative Research and Creative Technology, 2015, 01 (01), pp.11-14. 4. T.Krishnamoorthi, R.Girimurugan, M.Vairavel, Effects of Cathode Oxygen Concentration for Various Cell Potentials in a Six Pass Serpentine Flow Field Proton Exchange Membrane Fuel Cell – A Numerical Analysis, 2019, 09 (08), pp.224-232.

- 31. 5. S.Mayakannan, V .Rajesh, V.Jeeva Bharathi, M.Muthuraj, R.Girimurugan, Performance Studies on 25×25 cm2 Reactive Area Serpentine Flow Field Proton Exchange Membrane Fuel Cell with Different Cell Potentials, International Journal of Advance Research and Innovative Ideas in Education, 2015, 01 (05), pp.658-662. 6. R.Girimurugan, R.Kishorkumar, E.Manoj, D.Gowsal, P.Jayaprakash, Performance Analysis of PEM Fuel Cell with Six Pass Serpentine Flow Field under Various Operating Voltages, International Journal of Innovative Research and Creative Technology, 2015, 01 (01), pp.100-104. 7. Dr.R.Rajappan, G.Gurunathan, P.Paramadhayalan, S.Purushothaman, R.Girimurugan, Effect of Cell Potentials on Gas Diffusion Layer Velocity with Serpentine Flow Channel in PEM Fuel Cell, 2016, 02 (02), pp.61-65.

- 32. Thank You