Report

Share

Download to read offline

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Similar to Darcy weisbach formula

Similar to Darcy weisbach formula (20)

Effect of Height and Surface Roughness of a Broad Crested Weir on the Dischar...

Effect of Height and Surface Roughness of a Broad Crested Weir on the Dischar...

lab 4 requermenrt.pdfMECH202 – Fluid Mechanics – 2015 Lab .docx

lab 4 requermenrt.pdfMECH202 – Fluid Mechanics – 2015 Lab .docx

Studying Effect Inclination of cutoff on the percolation Length under Aprons ...

Studying Effect Inclination of cutoff on the percolation Length under Aprons ...

3 ijaems jun-2015-17-comparative pressure drop in laminar and turbulent flows

3 ijaems jun-2015-17-comparative pressure drop in laminar and turbulent flows

3 ijaems jun-2015-17-comparative pressure drop in laminar and turbulent flows

3 ijaems jun-2015-17-comparative pressure drop in laminar and turbulent flows

Recently uploaded

Recently uploaded (20)

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

Elevate Developer Efficiency & build GenAI Application with Amazon Q

Elevate Developer Efficiency & build GenAI Application with Amazon Q

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

WSO2 Micro Integrator for Enterprise Integration in a Decentralized, Microser...

WSO2 Micro Integrator for Enterprise Integration in a Decentralized, Microser...

AWS Community Day CPH - Three problems of Terraform

AWS Community Day CPH - Three problems of Terraform

Introduction to Multilingual Retrieval Augmented Generation (RAG)

Introduction to Multilingual Retrieval Augmented Generation (RAG)

Navigating Identity and Access Management in the Modern Enterprise

Navigating Identity and Access Management in the Modern Enterprise

TrustArc Webinar - Unified Trust Center for Privacy, Security, Compliance, an...

TrustArc Webinar - Unified Trust Center for Privacy, Security, Compliance, an...

Choreo: Empowering the Future of Enterprise Software Engineering

Choreo: Empowering the Future of Enterprise Software Engineering

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

Navigating the Deluge_ Dubai Floods and the Resilience of Dubai International...

Navigating the Deluge_ Dubai Floods and the Resilience of Dubai International...

Why Teams call analytics are critical to your entire business

Why Teams call analytics are critical to your entire business

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Decarbonising Commercial Real Estate: The Role of Operational Performance

Decarbonising Commercial Real Estate: The Role of Operational Performance

WSO2's API Vision: Unifying Control, Empowering Developers

WSO2's API Vision: Unifying Control, Empowering Developers

The Zero-ETL Approach: Enhancing Data Agility and Insight

The Zero-ETL Approach: Enhancing Data Agility and Insight

Darcy weisbach formula

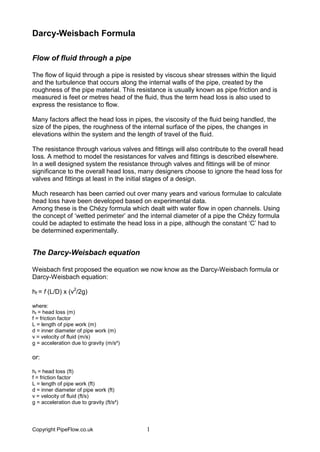

- 1. Copyright PipeFlow.co.uk 1 Darcy-Weisbach Formula Flow of fluid through a pipe The flow of liquid through a pipe is resisted by viscous shear stresses within the liquid and the turbulence that occurs along the internal walls of the pipe, created by the roughness of the pipe material. This resistance is usually known as pipe friction and is measured is feet or metres head of the fluid, thus the term head loss is also used to express the resistance to flow. Many factors affect the head loss in pipes, the viscosity of the fluid being handled, the size of the pipes, the roughness of the internal surface of the pipes, the changes in elevations within the system and the length of travel of the fluid. The resistance through various valves and fittings will also contribute to the overall head loss. A method to model the resistances for valves and fittings is described elsewhere. In a well designed system the resistance through valves and fittings will be of minor significance to the overall head loss, many designers choose to ignore the head loss for valves and fittings at least in the initial stages of a design. Much research has been carried out over many years and various formulae to calculate head loss have been developed based on experimental data. Among these is the Chézy formula which dealt with water flow in open channels. Using the concept of ‘wetted perimeter’ and the internal diameter of a pipe the Chézy formula could be adapted to estimate the head loss in a pipe, although the constant ‘C’ had to be determined experimentally. The Darcy-Weisbach equation Weisbach first proposed the equation we now know as the Darcy-Weisbach formula or Darcy-Weisbach equation: hf = f (L/D) x (v2 /2g) where: hf = head loss (m) f = friction factor L = length of pipe work (m) d = inner diameter of pipe work (m) v = velocity of fluid (m/s) g = acceleration due to gravity (m/s²) or: hf = head loss (ft) f = friction factor L = length of pipe work (ft) d = inner diameter of pipe work (ft) v = velocity of fluid (ft/s) g = acceleration due to gravity (ft/s²)

- 2. Copyright PipeFlow.co.uk 2 However the establishment of the friction factors was still an unresolved issue which needed further work. Friction Factors Fanning did much experimentation to provide data for friction factors, however the head loss calculation using the Fanning Friction factors has to be applied using the hydraulic radius equation (not the pipe diameter). The hydraulic radius calculation involves dividing the cross sectional area of flow by the wetted perimeter. For a round pipe with full flow the hydraulic radius is equal to ¼ of the pipe diameter, so the head loss equation becomes: hf = f f(L/Rh) x (v2 /2g) where Rh = hydraulic radius, f f = Fanning friction factor Darcy introduced the concept of relative roughness, where the ratio of the internal roughness of a pipe to the internal diameter of a pipe, will affect the friction factor for turbulent flow. In a relatively smoother pipe the turbulence along the pipe walls has less overall effect, hence a lower friction factor is applied. The work of many others including Poiseuille, Hagen, Reynolds, Prandtl, Colebrook and White have contributed to the development of formulae for calculation of friction factors and head loss due to friction. The Darcy Friction factor (which is 4 times greater than the Fanning Friction factor) used with Weisbach equation has now become the standard head loss equation for calculating head loss in pipes where the flow is turbulent. Initially the Darcy-Weisbach equation was difficult apply, since no electronic calculators were available and many calculations had to be carried out by hand. The Colebrook-White equation which provides a mathematical method for calculation of the friction factor (for pipes that are neither totally smooth nor wholly rough) has the friction factor term f on both sides of the formula and is difficult to solve without trial and error (i.e. mathematical iteration is normally required to find f). fD e f Re 35.9 log214.1/1 10 for Re > 4000 where: f = friction factor e = internal roughness of the pipe D = inner diameter of pipe work Due to the difficulty of solving the Colebrook-White equation to find f, the use of the empirical ‘Hazen-Williams’ formulae for flow of water at 60º F (15.5º C) has persisted for many years. To use the Hazen-Williams formula a head loss coefficient must be used. Unfortunately the value of the head loss coefficient can vary from around 80 up to 130 and beyond and this can make the ‘Hazen-Williams’ formulae unsuitable for accurate prediction of head loss. The Moody Chart

- 3. Copyright PipeFlow.co.uk 3 In 1944 LF Moody plotted the data from the Colebrook equation and this chart which is now known as ‘The Moody Chart’ or sometimes the Friction Factor Chart, enables a user to plot the Reynolds number and the Relative Roughness of the pipe and to establish a reasonably accurate value of the friction factor for turbulent flow conditions. The Moody Chart encouraged the use of the Darcy-Weisbach friction factor and this quickly became the method of choice for hydraulic engineers. Many forms of head loss calculator were developed to assist with the calculations, amongst these a round slide rule offered calculations for flow in pipes on one side and flow in open channels on the reverse side. The development of the personnel computer from the 1980’s onwards reduced the time needed to perform the friction factor and head loss calculations, which in turn has widened the use of the Darcy-Weisbach formula to the point that all other formula are now largely unused.