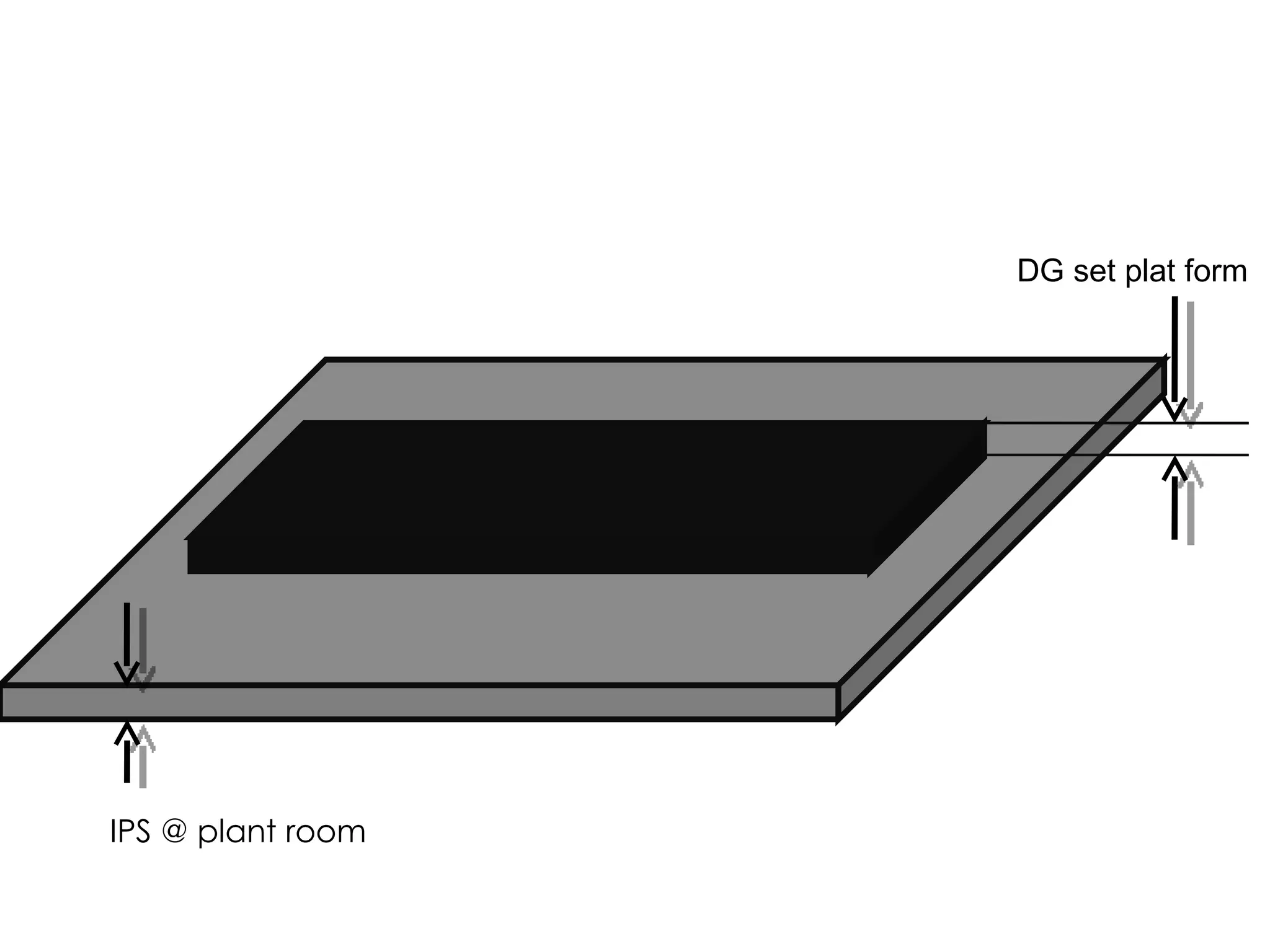

The document outlines the flow of activities required for installing a diesel generator, including preparing the plant room with adequate space and clearances, finalizing locations for the fuel tank and routing of pipes and cables according to consultant drawings, ensuring drainage and fire safety equipment are in place, and conducting civil works like constructing the platform and trenching for the fuel tank, pipes, and cables.