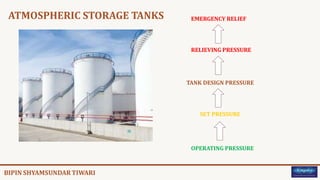

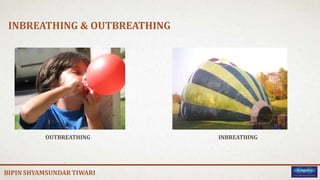

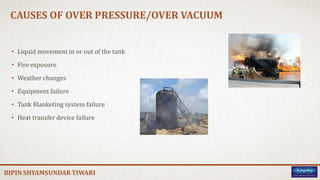

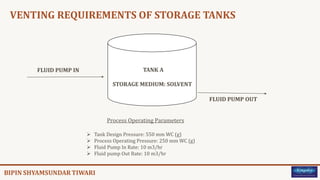

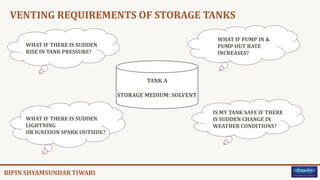

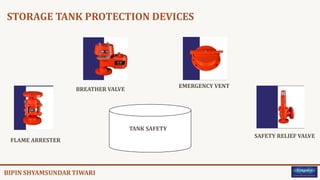

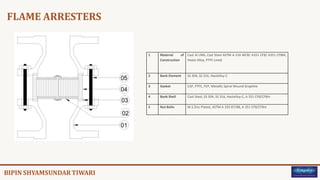

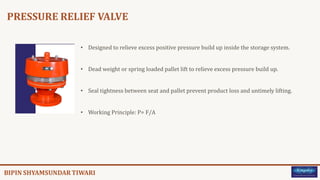

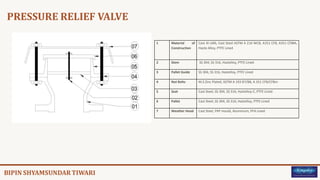

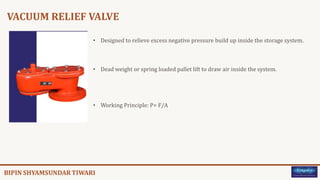

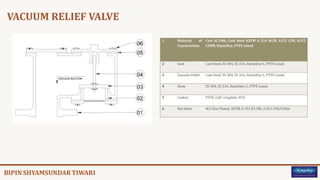

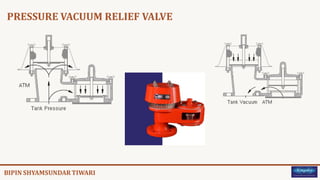

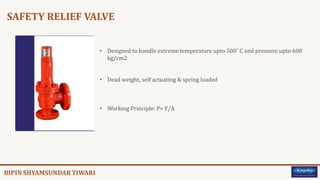

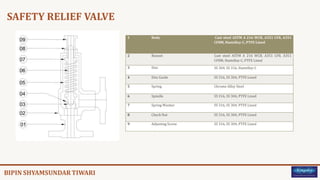

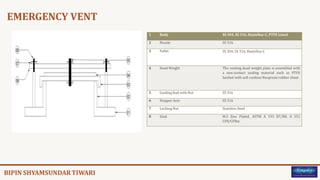

The document outlines the safety requirements and risk management practices for atmospheric storage tanks, emphasizing the importance of venting and various protection devices such as flame arresters, breather valves, and safety relief valves. It details the causes of overpressure and vacuum situations, the functioning of various safety devices, and the materials used in their construction. Additionally, it highlights the importance of maintaining operational parameters and inspecting for potential risks like leakage and corrosion.