The document provides an overview of enclosure thermal management, detailing the necessity for controlling temperature within industrial enclosures housing electrical components to prevent overheating and condensation. It discusses heating and cooling mechanisms, emphasizing convection, and outlines considerations for selecting heaters, including calculations for required heating power based on enclosure size and environmental conditions. Various methods for cooling enclosures, including natural, forced, and closed-loop systems, are also described, along with products suitable for each method.

![Sizing an Air Conditioner (continued)

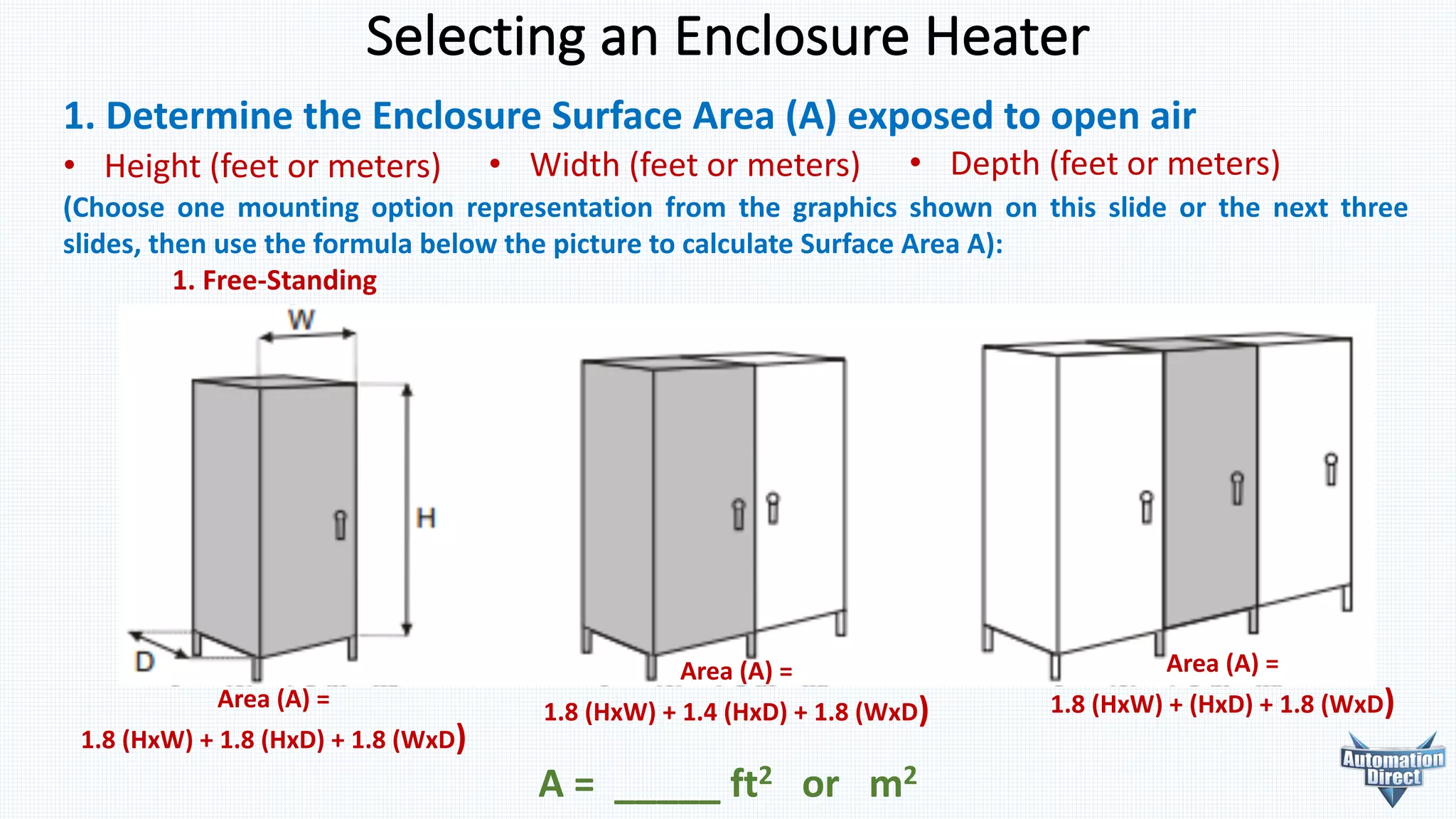

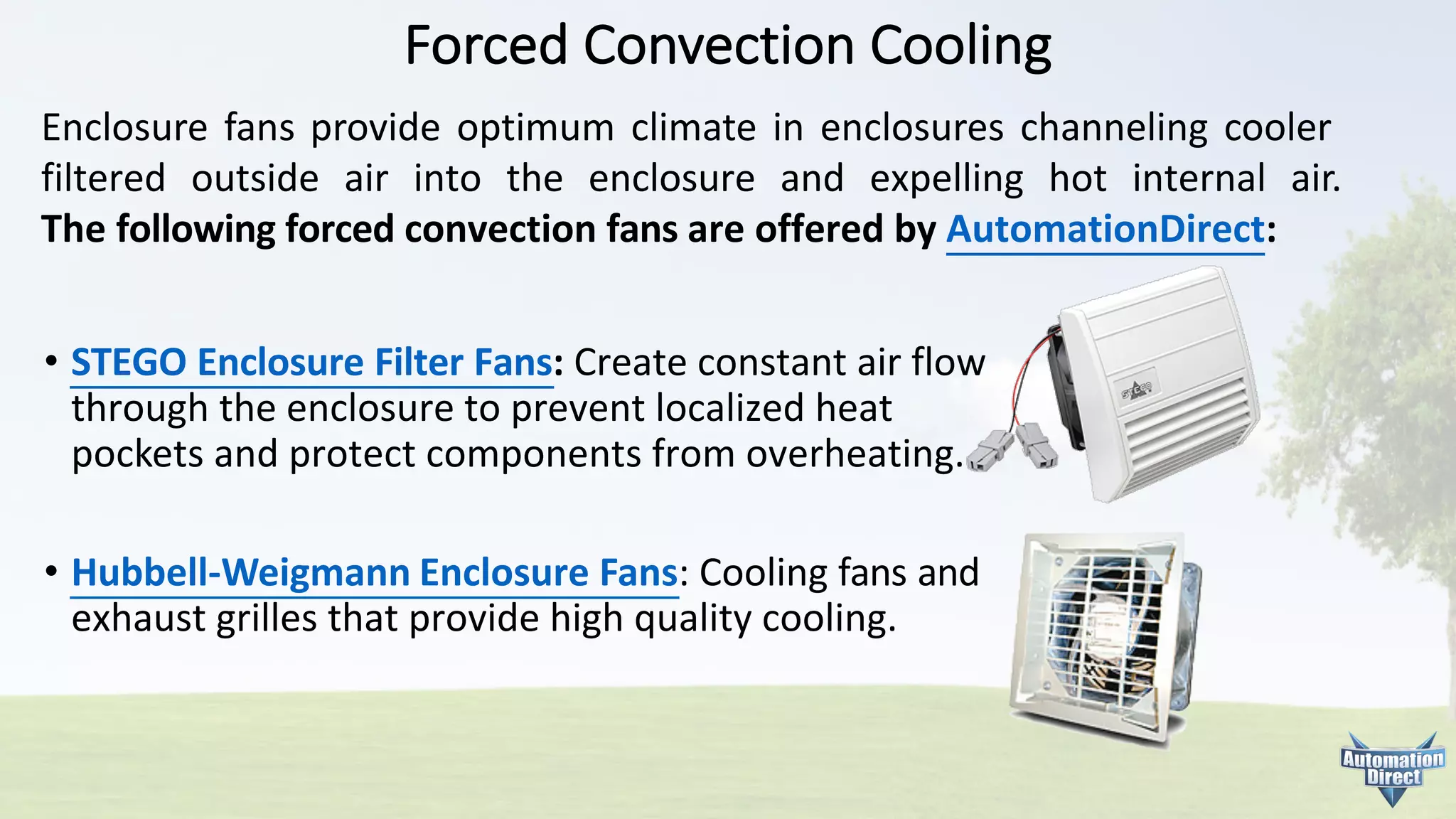

Note: 1.25 is an industry standard constant for metal enclosures;

for plastic enclosures use 0.62.

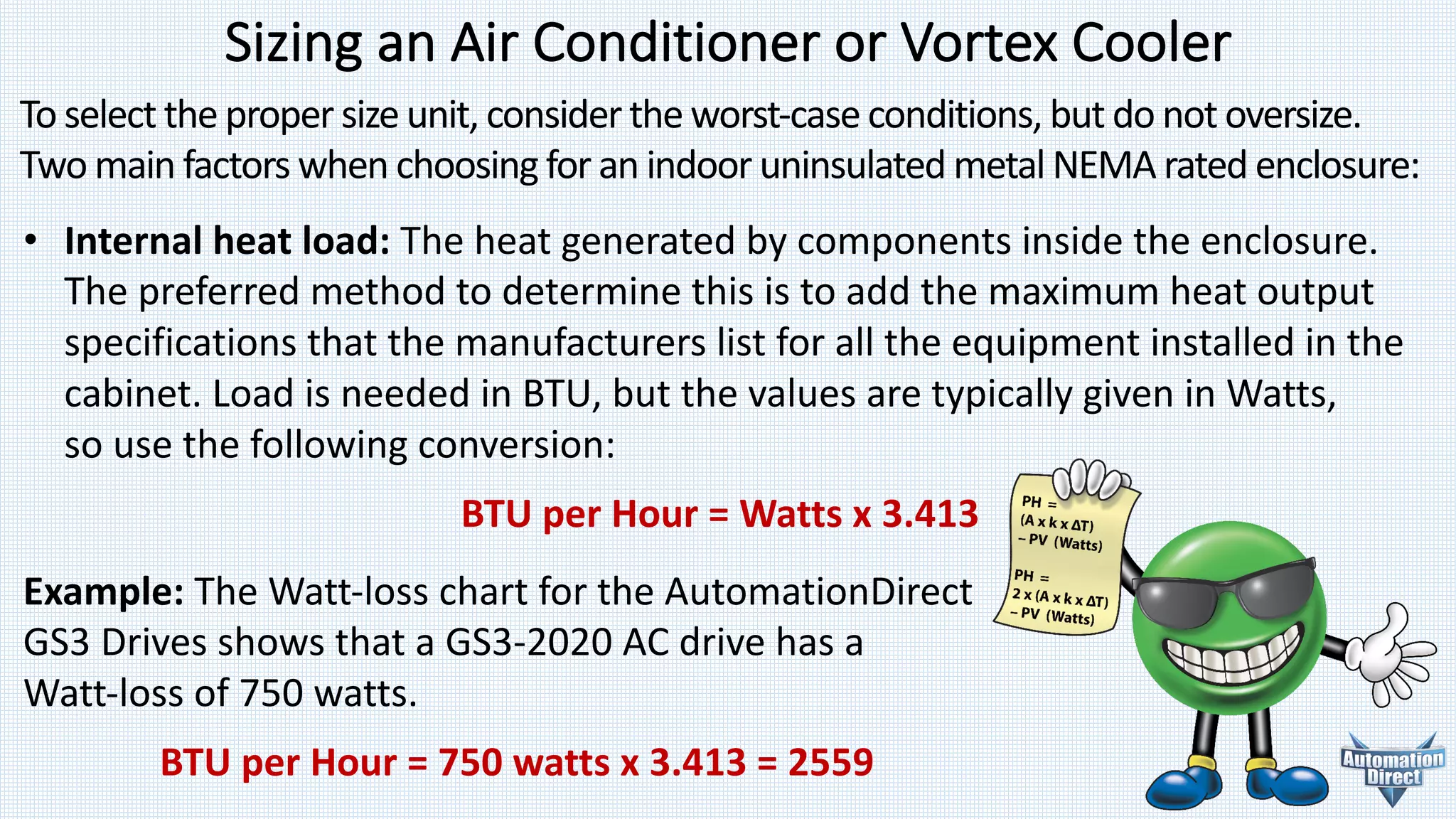

• Heat Load Transfer: The heat lost (negative heat load transfer) or gained

(positive heat load transfer) through the enclosure walls with the surrounding

ambient air. Calculate using the following formula:

Heat load transfer (BTU/H) =

1.25 x surface area (sq. ft. ) x (max. outside ambient air (°F) –

max. allowable internal enclosure temperature air (°F)) Surface Area (sq. ft.) =

2 [(H x W) + (H x D) + (W x D)] / 144 sq. inches

Cooling capacity (BTU/H) = Internal Heat Load ± Heat Load Transfer

Once you determine the Internal Heat Load and the Heat

Load Transfer, you can choose the proper size unit

by calculating the needed cooling capacity.](https://image.slidesharecdn.com/enclosureclimatecontrolslideshare020817-170210112819/75/Enclosure-Thermal-Management-Product-Types-and-Selection-Overview-48-2048.jpg)

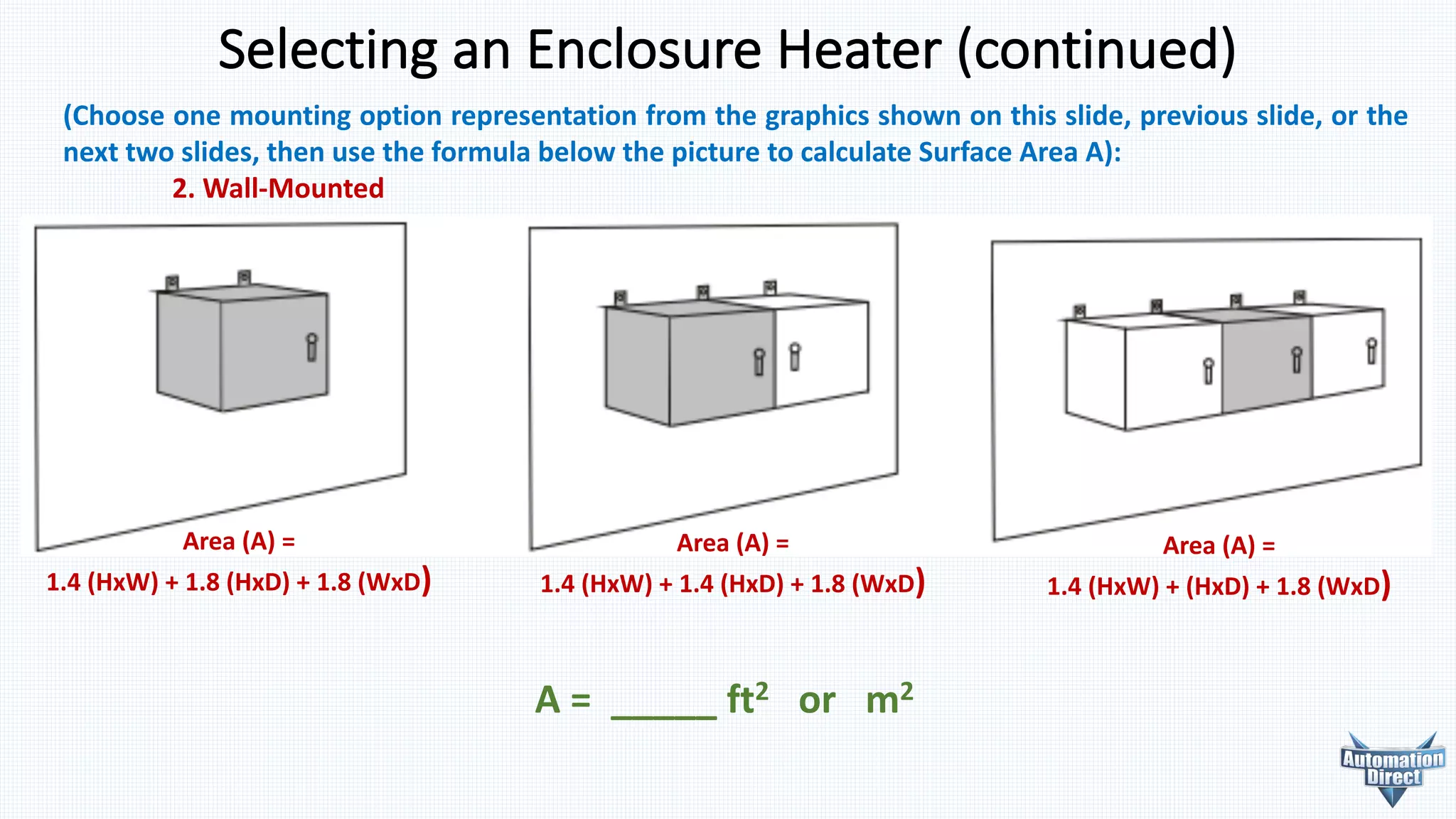

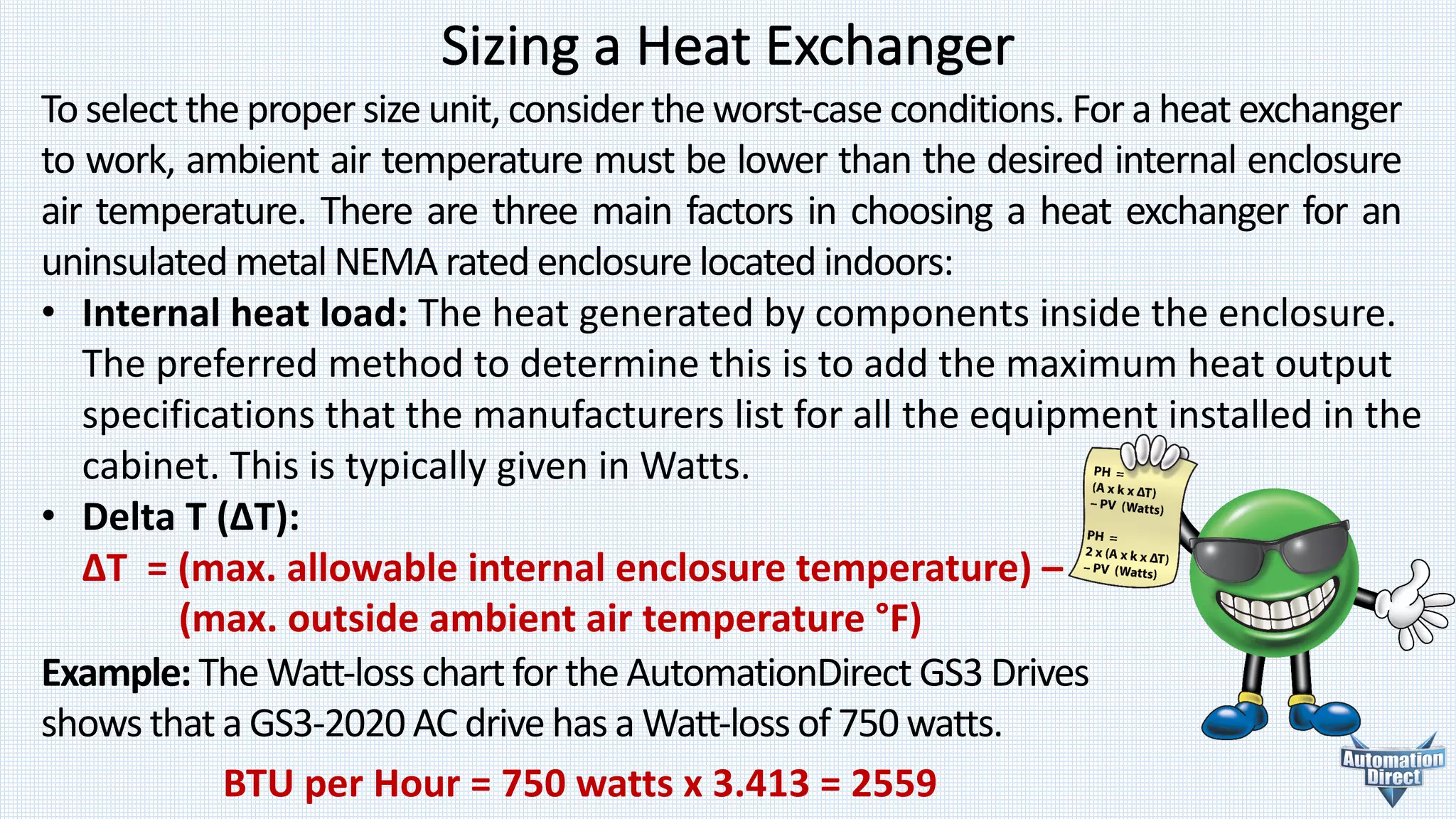

![Sizing a Heat Exchanger (continued)

Note: Only include exposed surfaces.

Heat Load Transfer (W/°F) = 0.22 W/°F sq. Ft. x Surface Area

Note: Use 0.22 Watts/°F sq. ft. for painted stainless and non-

metallic enclosures. Use 0.10 Watts/°F sq. ft. for stainless

steel and bare aluminum enclosures.

Once you determine the Internal Heat Load and theHeat Load

Transfer and the Delta T, you can choose the proper size unit

by calculating the needed cooling capacity.

• Heat Load Transfer: The heat lost (negative heat load transfer) or gained

(positive heat load transfer) through the enclosure walls with the surrounding

ambient air. Calculate using the following formula:

Surface Area (sq. ft.) = 2 [(H x W) + (H x D) + (W x D)] / 144 sq. inches

Cooling capacity (W/°F) = Internal Heat Load / ΔT - Heat Load Transfer](https://image.slidesharecdn.com/enclosureclimatecontrolslideshare020817-170210112819/75/Enclosure-Thermal-Management-Product-Types-and-Selection-Overview-53-2048.jpg)

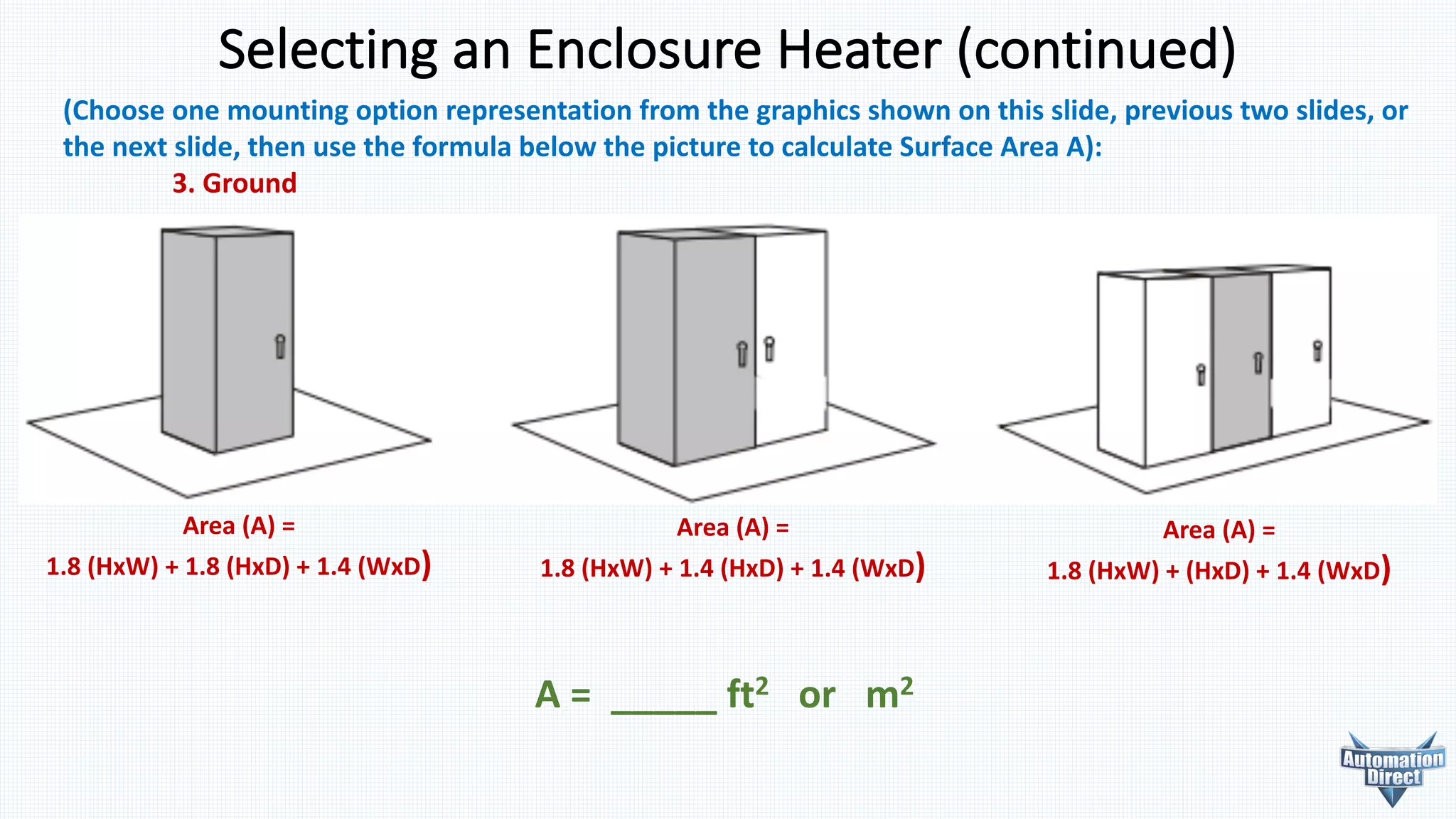

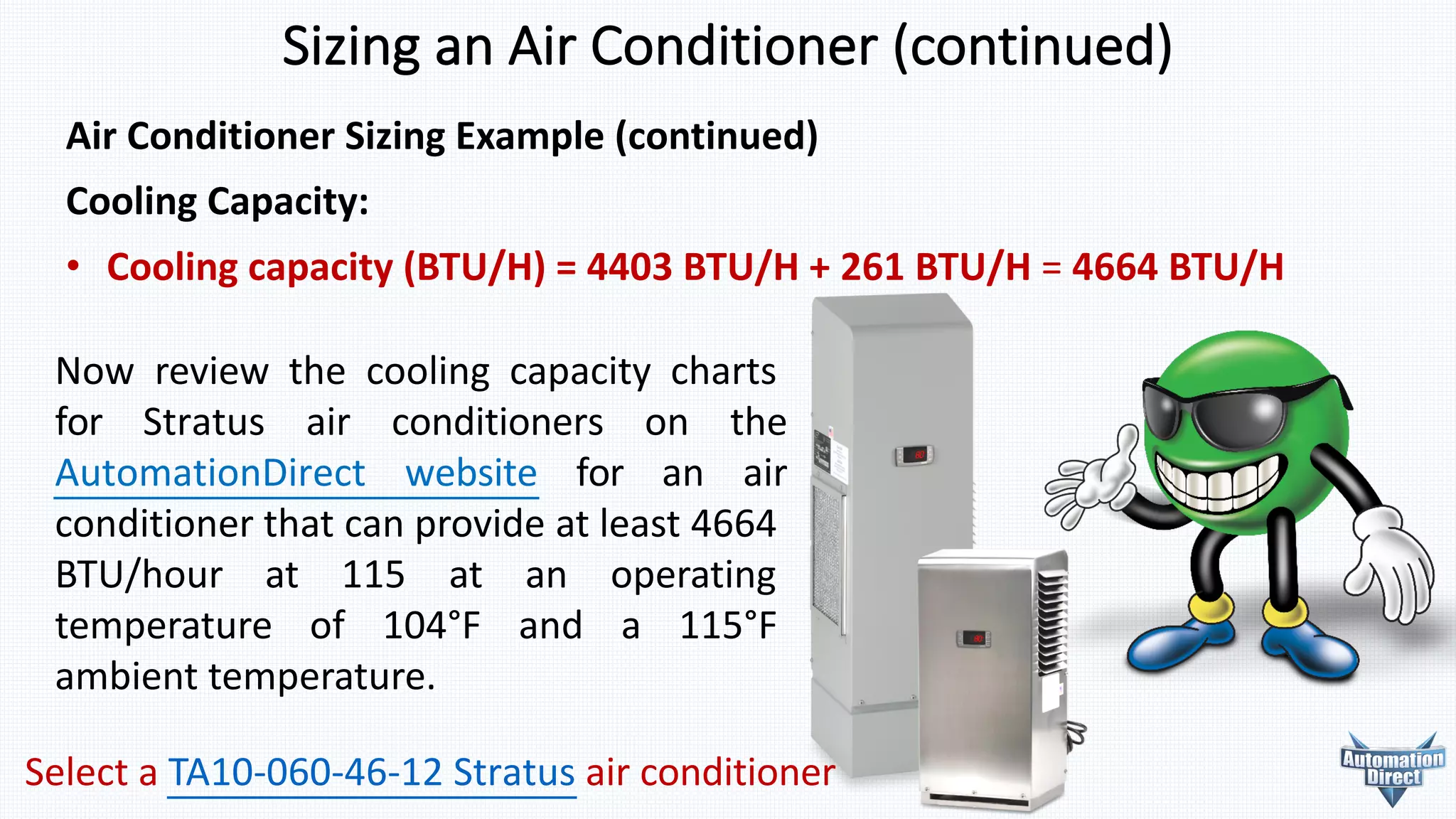

![Surface Area (ft.2) = 2 [ (30 x 24) + (30 x 12) + (24 x 12) ] / 144 sq. inches = 19 ft.2

Heat load transfer = 0.22 x 19 ft.2 = 4.2 Watts/°F

Selecting a Heat Exchanger (continued)

Heat Exchanger Selection Example

A NEMA 12 Hubbell Wiegmann N12302412 enclosure (30ʺ high x 24ʺ wide x 12ʺ

deep) contains a GS3-4010 AC drive (10 HP 460 volt) that has a maximum allowable

operating temperature of 104°F and is located in a warehouse that has a maximum

outside ambient air temperature of 90°F. Power to be dissipated is stated in the

specificationsoftheGS3-4010andisfoundtobe345Watts.

Internal Heat Load = 345 Watts

Delta T (ΔT ) = 104°F – 90°F = 14°F

Heat load transfer:](https://image.slidesharecdn.com/enclosureclimatecontrolslideshare020817-170210112819/75/Enclosure-Thermal-Management-Product-Types-and-Selection-Overview-54-2048.jpg)