CV of QC Welding Inspector

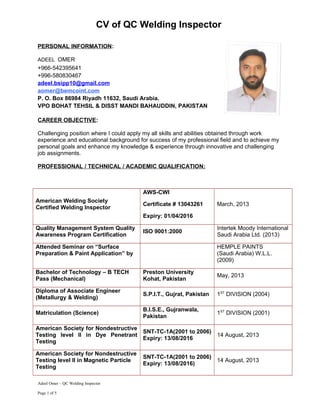

- 1. CV of QC Welding Inspector PERSONAL INFORMATION: ADEEL OMER +966-542395641 +996-580830467 adeel.bsipp10@gmail.com aomer@bemcoint.com P. O. Box 86984 Riyadh 11632, Saudi Arabia. VPO BOHAT TEHSIL & DISST MANDI BAHAUDDIN, PAKISTAN CAREER OBJECTIVE: Challenging position where I could apply my all skills and abilities obtained through work experience and educational background for success of my professional field and to achieve my personal goals and enhance my knowledge & experience through innovative and challenging job assignments. PROFESSIONAL / TECHNICAL / ACADEMIC QUALIFICATION: American Welding Society Certified Welding Inspector AWS-CWI Certificate # 13043261 Expiry: 01/04/2016 March, 2013 Quality Management System Quality Awareness Program Certification ISO 9001:2000 Intertek Moody International Saudi Arabia Ltd. (2013) Attended Seminar on “Surface Preparation & Paint Application” by HEMPLE PAINTS (Saudi Arabia) W.L.L. (2009) Bachelor of Technology – B TECH Pass (Mechanical) Preston University Kohat, Pakistan May, 2013 Diploma of Associate Engineer (Metallurgy & Welding) S.P.I.T., Gujrat, Pakistan 1ST DIVISION (2004) Matriculation (Science) B.I.S.E., Gujranwala, Pakistan 1ST DIVISION (2001) American Society for Nondestructive Testing level II in Dye Penetrant Testing SNT-TC-1A(2001 to 2006) Expiry: 13/08/2016 14 August, 2013 American Society for Nondestructive Testing level II in Magnetic Particle Testing SNT-TC-1A(2001 to 2006) Expiry: 13/08/2016) 14 August, 2013 Adeel Omer – QC Welding Inspector Page 1 of 5

- 2. American Society for Nondestructive Testing level II in Radiographic Testing SNT-TC-1A(2001 to 2006) Expiry: 13/08/2016 14 August, 2013 CODES FAMILIARITY: Well versed with codes such as ASME Sec II part A & C, ASME Sec. V, ASME Sec. VIII, ASME Sec. IX, ASME B31.1, ASME B31.3, API 650, API 1104, API 620, API 653, AWS D1.1 COMPUTER SKILLS: Well versed with following applications: Microsoft Word, Microsoft Excel AutoCAD Application Microsoft Power Point MS Office PROFESSIONAL EXPERIENCE: Company : Arabian Bemco Contracting Company Project : Combine Cycle Power Plant PP-10 Riyadh, KSA Position : QC Welding Inspector Duration : March 2012 to Present DUTIES & RESPONSIBILITIES: 1. Review the Project scope of work and look after the construction activities as per applicable standards and specifications. 2. Monitoring the Piping and Structural work as per drawings. 3. Update the welders Qualification and records. 4. Preparing the welding Summary sheets. 5. To maintain welders / welding operators continuity log and weekly/monthly/yearly repair rate. 6. Interpreting Codes / Standards / Specifications related to assigned jobs. 7. To prepare and certification of Welding Procedure Specification (WPS) and conduct procedure Qualification test. 8. To maintain welders / welding operators continuity log. 9. To Assign QC Welding Inspectors to their respective jobs. 10. Preparation of test packages including all reports. 11. Conduct Training for Welders / Welding Operators. 12. To prepare punch listing and coordination and involvement of required all non- destructive testing required as per standards and project specifications. 13. To review the MTRs of welding Consumables according to ASME Code and review the Lab test reports of Procedure Qualification, Welder Qualification, Production test plate and welding Consumables. 14. To raise CARs against non-conformances. 15. To ensure welding works are performed as per approved WPS and only qualified welders performed welding works. Adeel Omer – QC Welding Inspector Page 2 of 5

- 3. 16. Maintain calibration record of welding machines, electrode backing ovens and all inspection tools and equipments. 17. To communicate welding procedures, preheat, interpass temperature and all other necessary documents to welding supervisors and welders/welding operators. 18. To supervise preheat & PWHT activities of Alloy Steel piping (P11, P22, P91 etc) 19. Fit-up inspection of piping as per approve drawings 20. Welding inspection of piping 21. To conduct line check for piping 22. Hydrostatic & Pneumatic test of piping 23. Flushing and reinstate of piping & punch listing 24. Co-ordination with Customer Inspector, Sec representatives and ASME Authorized Inspector. Company : BEMCO Steel Industries, Riyadh, KSA Project : PP-9, PP-10, Qurayyah, Qurrayat Position : Sr. Welding Inspector Duration : October 2006 to March 2012 MAJOUR PROJECTS in BEMCO Steel Industries: 1. Combine Cycle Power Plant # 10 Riyadh (7EA GE Turbine with 40 Turbines & 40 HRSG, 8 Floating Roof & 10 Fixed Roof Tanks ) DUTIES & RESPONSIBILITIES: 1. To prepare and certification of Welding Procedure Specification (WPS) and conduct procedure Qualification test. 2. To maintain welders / welding operators continuity log. 3. Qualification of welders / welding operators in accordance with ASME Sec IX & AWS D1.1 4. Prequalification of welders / welding operators. 5. To indent the required Welding Consumables list for at least a month according to projects to be fabricated. 6. To prepare the Weld Map and Weld Matrix for the ASME Coded Pressure Vessels 7. Preparation of test packages including all reports. 8. To witness the hydrostatic test as per requirements of standards and specification. 9. To prepare punch listing and coordination and involvement of required all non- destructive testing required as per standards and project specifications. 10. To review the MTRs of welding Consumables according to ASME Code and review the Lab test reports of Procedure Qualification, Welder Qualification, Production test plate and welding Consumables. 11. To raise CARs against non-conformances. 12. To ensure welding works are performed as per approved WPS and only qualified welders performed welding works. 13. Maintain Consumables Issuance record. 14. Maintain calibration record of welding machines, electrode backing ovens and all inspection tools and equipments. 15. To deploy the welders on the job as per their qualification with each process and thickness range. 16. To communicate welding procedures, preheat, interpass temperature and all other necessary documents to welding supervisors and welders/welding operators. 17. To supervise preheat & PWHT activities of Alloy Steel piping (P11, P22, P91 etc) Adeel Omer – QC Welding Inspector Page 3 of 5

- 4. 18. Fit-up inspection of piping as per approve drawings 19. Welding inspection of piping 20. To conduct line check for piping 21. Hydrostatic & Pneumatic test of piping 22. Flushing and reinstate of piping & punch listing 23. Reviewing of Shop Drawings, Customer Specifications and Procedures. 24. Interpreting Codes / Standards / Specifications related to assigned jobs. 25. Co-ordination with Customer Inspector, ASME Authorized Inspector. 26. Coordinating with ASME auditors for the final audit to review ASME mark stamps. MAJOUR PROJECTS in BEMCO Steel Industries: 2. Combine Cycle Power Plant # 09 Riyadh (7EA GE Turbine with 32 Turbines & 16 HRSG) 3. Qurayyah Combine Cycle Power Plant (9EA GE Turbine with 15 Turbines & 15 HRSG) 4. Qurrayat Open Cycle Power Plant. Company : DDFC Pvt. Ltd. Lahore PAKISTAN Project : Fabrication Shop (PPL, Chemical Industries, Packages Ltd Etc.) Position : QC Welding Inspector Duration : July 2004 to September 2006 DUTIES & RESPONSIBILITIES: 1. Visual inspections of Welding of all parts of ASME Pressure Vessels, Boilers and steel structure. 2. Performing all Dye Penetrant Test, Interpret their result and prepare reports of them of all parts of Boilers and Pressure vessels. 3. To conduct Welder / Welding Operator’s Qualification test in accordance with ASME Section IX. 4. To maintain welders / welding operators continuity log. 5. Prequalification of welders / welding operators. 6. To ensure welding works are performed as per approved WPS and only qualified welders performed welding works. 7. Interpreting Codes / Standards / Specifications related to assigned jobs. 8. Material identification inspections of pressure parts and keeping their records. 9. Fit up of Assemblies Inspections. 10. Visual & Dimensional inspection of ASME coded pressure vessels as per code applicable code of construction and other Specifications at different stages to ensure the quality of job. 11. Reviewing of MTRs or Laboratory Test Reports according to applicable specifications. 12. To perform the final dimensional inspection of coded jobs. 13. Hydrostatic/Pneumatic/Water fill Test inspections. 14. Co-ordination with Client Inspector, ASME Authorized Inspector, Third party inspectors to implement their hold points. 15. To prepare Manufacturing Data Reports. 16. Maintain record of all documents related to the ASME coded jobs. 17. Inspection of sand blasting to surface SA-3, SA 2.5, SA 2 etc. 18. Surface preparation and protective coatings inspections. Adeel Omer – QC Welding Inspector Page 4 of 5

- 5. 19. Overall execution of the job after design till installation. 20. Managing and Review quality records for final handing over dossiers / IDM / MDM. 21. Interpreting Codes / Standards / Specifications related to assigned jobs. 22. Coordinating with ASME authorized inspector to implement Quality Control System to control the fabrication activities. 23. Incoming materials inspection to ensure the conformance to project specifications according to applicable specifications and related procedure. 24. Final inspection of U-Stamped jobs 25. Coordinating with ASME auditors for the final audit to review ASME mark stamps. MAJOUR PROJECTS in DDFC Pvt. Ltd.: 1. LPG/NGL Spherical Storage tank, De-Ethanizer Overhead Drums, Three Phase Production Separators, Air Receiver Vessels, De-Ethanizer Vertical Columns, LPG/NGL Splitter Columns, Low Temperature Expender Suction Drums for LPG/NGL Plant Phase II of Pakistan Petroleum Limited. (ASME “U” Stamped). 2. Low Temperature Separators, Slops Tank, Chilled Water Expansion Tanks, Scrubbers and Water Degassing Boots for LPG/NGL Plant Phase II of Pakistan Petroleum Limited. (ASME “U” Stamped). 3. Three Phase Production Separator for OGDCL, Pakistan. 4. 20 TPH Fired Tube Boiler and Stainless Steel Chemical Storage Tanks for Coca Cola Beverages, Afghanistan. 5. Fired Tube & Waste Heat Recovery Boilers, Economizers, Feed Water Tanks and Distillery Equipments for various national and multinational customers. 6. Stainless Steel Digester Tubes for Packages Private Limited, Pakistan. 7. DAS unit of Waste Water Treatment Plant for BHP Billiton Limited, Pakistan. License PERSONAL DETAILS: NAME: ADEEL OMER FATHER’S NAME: OMER HAYAT PASPORT NO: AF2223512 DRIVING LICENSE: SAUDI ARABIA NATIONALITY: PAKISTANI RELIGION: ISLAM DATE OF BIRTH: 05.06.1985 PERMANENT ADRESS: VPO BOHAT KHAS TEHSIL AND DISTRICT MANDI BAHAUDDIN, PUNJAB, PAKISTAN. E MAIL ADRESS: adeel.bsipp10@gmail.com aomer@bemcoint.com TELEPHONE NO: +966542395641, +966580830467 +92546575075 Certificates will be furnished on demand. (ADEEL OMER) Adeel Omer – QC Welding Inspector Page 5 of 5

- 6. 19. Overall execution of the job after design till installation. 20. Managing and Review quality records for final handing over dossiers / IDM / MDM. 21. Interpreting Codes / Standards / Specifications related to assigned jobs. 22. Coordinating with ASME authorized inspector to implement Quality Control System to control the fabrication activities. 23. Incoming materials inspection to ensure the conformance to project specifications according to applicable specifications and related procedure. 24. Final inspection of U-Stamped jobs 25. Coordinating with ASME auditors for the final audit to review ASME mark stamps. MAJOUR PROJECTS in DDFC Pvt. Ltd.: 1. LPG/NGL Spherical Storage tank, De-Ethanizer Overhead Drums, Three Phase Production Separators, Air Receiver Vessels, De-Ethanizer Vertical Columns, LPG/NGL Splitter Columns, Low Temperature Expender Suction Drums for LPG/NGL Plant Phase II of Pakistan Petroleum Limited. (ASME “U” Stamped). 2. Low Temperature Separators, Slops Tank, Chilled Water Expansion Tanks, Scrubbers and Water Degassing Boots for LPG/NGL Plant Phase II of Pakistan Petroleum Limited. (ASME “U” Stamped). 3. Three Phase Production Separator for OGDCL, Pakistan. 4. 20 TPH Fired Tube Boiler and Stainless Steel Chemical Storage Tanks for Coca Cola Beverages, Afghanistan. 5. Fired Tube & Waste Heat Recovery Boilers, Economizers, Feed Water Tanks and Distillery Equipments for various national and multinational customers. 6. Stainless Steel Digester Tubes for Packages Private Limited, Pakistan. 7. DAS unit of Waste Water Treatment Plant for BHP Billiton Limited, Pakistan. License PERSONAL DETAILS: NAME: ADEEL OMER FATHER’S NAME: OMER HAYAT PASPORT NO: AF2223512 DRIVING LICENSE: SAUDI ARABIA NATIONALITY: PAKISTANI RELIGION: ISLAM DATE OF BIRTH: 05.06.1985 PERMANENT ADRESS: VPO BOHAT KHAS TEHSIL AND DISTRICT MANDI BAHAUDDIN, PUNJAB, PAKISTAN. E MAIL ADRESS: adeel.bsipp10@gmail.com aomer@bemcoint.com TELEPHONE NO: +966542395641, +966580830467 +92546575075 Certificates will be furnished on demand. (ADEEL OMER) Adeel Omer – QC Welding Inspector Page 5 of 5