Shrinkage

- 1. Shrinkage

- 2. Name : MAZADUL HASAN SHESHIR ID: 2010000400008 Batch: 13th Batch (Session 2009-2013) Department: Wet Processing Technology Email: mazadulhasan@yahoo.com (FB) Blog: www. Textilelab.blogspot.com Southeast University,Bangladesh Department of Textile Engineering PREPARED BY ©right

- 3. Shrinkage Definition : A dimensional change resulting in a decrease in the length or width of a specimen subjected to specified conditions is known shrinkage. Reduction in length and width of fabric induced by conditioning, wetting, steaming, chemical treatment, wet processing as in laundering, in chemical practice and in literature the following terms have been used to describe the shrinkage which occurs in testing procedure: 1. Relaxation shrinkage, 2. Felting shrinkage, 3. Compressive shrinkage, 4. Residual shrinkage. Shrinkage

- 4. Shrinkage: Shrinkage is the process in which a fabric becomes smaller than its original size, usually through the process of laundry. Cotton fabric suffers from two main disadvantages of shrinking and creasing during subsequent washing. There are two types of shrinkage occurs during washing 1) Length wise 2) Width wise Shrinkage

- 5. Cause: Due to high tension during preparation of fabric which result in excess stretch in yarn. This type of shrinkage is known as London shrinkage. Due to swelling of fibers for fiber structure. Glass plate Shrinkage

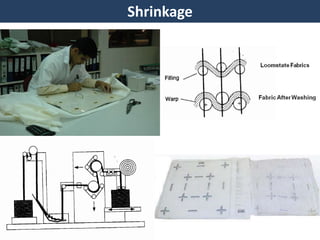

- 6. Illustration of Shrinkage on Woven Fabric Caused by Fiber and Yarn Swelling

- 7. There are Two Kinds of Fabric Shrinkage: 1. Relaxation Shrinkage 2. Progressive Shrinkage Relaxation Shrinkage This occurs because the fibers and yarns are under tension when the fabrics are made. Later when the fabric is wet in a tensionless condition, relaxation occurs. Progressive Shrinkage This occurs each time a fabric is laundered. Unlike relaxation shrinkage which occurs only once, progressive shrinkage continues and the fabric shrinks a bit more with each laundering. Of the major fibers, only wool and viscose rayon are subject to progressive shrinkage. Shrinkage : Types

- 8. Relaxation shrinkage: During manufactures fabrics and their component yarns are subjeceted to tension under varying conditions of temperature and moisture content, after manufacturing when the fabric is taken from the machine and keep on floor or store room, then the fabric tends to shrink, this type shrinkage is called relaxation shrinkage. Felting shrinkage: In case of wool fibers dimensional changes can be magnified by felting shrinkage. When untreated wool fibers are subjected to mechanical action in the presence of moisture. Compressive shrinkage: A process in which fabric is caused to shrink in length by compression. The process often referred to as controlled compressive shrinkage. Residual shrinkage: after washing the fabric is shrunk. This type of shrinkage is called residual shrinkage. Residual shrinkage is the main factor of garments industry. Shrinkage: Types

- 9. Causes: Shrinkage is mainly due to yarn swelling and the resulting crimp increase during washing in case of cotton fabrics. Yarn swelling percentage is more in polyester cotton blending yarn. Influencing factors: Twist factor: twist factor increases so that shrinkage will be increases. Stitch length: stitch length increases so that shrinkage will be increases. GSM: GSM increases so that shrinkage will be decreases. Elasticity of yarn. Shrinkage : Causes-Influencing factors

- 10. The factors that control shrinkage in fabrics or garments are: • Construction: A tighter fabric construction reduces potential shrinkage • Yarn twist: Optimum twist (based on yarn size) is very important for controlling shrinkage and torque. • Type of Weave or Knit: Pain weave of Jersey knit show more resistance to shrinkage than other types. • Tension During Sewing of Garments: Uneven or too much sewing tension can lead to differential shrinkage causing puckering in the seam areas. • Stability of Fiber and Yarns: Improper stabilization could lead to excessive shrinkage especially in blends where synthetic fiber shrinks differentially than the cellulosic fibers. Shrinkage : Factors

- 11. Shrinkage control is based on the following factors : 1. correct knitted construction is essential 2. excessive tensions should be eliminated during processing (from grey inspection to finishing) 3. untwisting and extraction to below 65% moisture content 4. padding the correct softener on to the fabric 5. spreading with overfeed and pre-drying to approximately 30% moisture content 6. step by step shrinkage reduction. Computer programs have been developed in an attempt to reliably predict the shrinkage and dimensional properties of finished, knitted cotton fabrics using a database of processed fabrics of known construction, processing sequences and performance. This was given the name Starfish – start as you mean to finish! Dry finishing processes are usually restricted to brushing (particularly for fleece fabrics) and cropping. These processes and their associated machinery have been discussed in section. Shrinkage control

- 12. Compressive Shrinkage (Relaxation Method) Used for woven cotton, tubular knit cotton, linen and rayon; the method consists of mechanically compressing the fabric lengthwise by overfeeding onto a large roller with damp blankets. Sanforized is a well known trade mark for fabrics treated by this method. Heat Set (Relaxation Method) Used for fabrics from thermoplastic fibers such as nylon, polyester and acrylic; it is based on the principle that thermoplastic materials will become stabilized in their configuration in which they happen to be when heated to their softening temperature. Finishing that Alter Durability ― Shrinkage Control

- 13. Sponging (Relaxation Method) » Used for woolen and worsted fabrics; it consists of thoroughly wetting the fabric with water or steam and allowing the material to dry slowly in a relaxed tensionless state. This does not make wool washable or shrink-proof; it permits wool to be steam pressed or caught in rain without severe shrinking. Resin Treatments (Relaxation Method) » Used for fabrics of rayon and cotton; it involves impregnating rayon and cotton with resins and then curing which stabilizes the fabric and thus reduces its tendency to distort. Resins also provide crease resistance. It is preferable to hand wash resin treated rayon fabrics. Finishing that Alter Durability ― Shrinkage Control

- 14. Rubber Belt Principle Compressive Shrinkage

- 15. Belt Principle for Imparting Mechanical Shrinkage for Knits

- 16. Shrinkage Remover By Morrison

- 17. For open-width knit fabrics based on cavity type overfeeding The Micrex Process Shrinkage Control of Knit Fabrics

- 18. Construction Shrinkage: After a cotton fabric is constructed on a knitting machine or weaving loom, it has inherent characteristics based solely on the yarn construction variables used.These characteristics or conditions are referred to as the greige delivered state and can be tested for various specifications including shrinkage. The type of shrinkage measured at this point is defined as construction shrinkage. Construction shrinkage is defined as the amount of dimensional change in a fabric based solely on the construction variables used to create the fabric. It is measured after fabrication but before subsequent processes. Construction Shrinkage

- 19. Processing Shrinkage: All processing steps in a dyeing and finishing plant and in an apparel manufacturing operation affect the dimensions of a product. Some techniques have more impact than others. These steps create processing shrinkage, which can be defined as the dimensional change that a process adds to or removes from the construction shrinkage of a fabric, and thereby changes the residual shrinkage accordingly. Length and width dimensions are both affected, and the fabrics may either be stretched or consolidated. Most often, the length is stretched and the width is reduced during wet processing. Some of this shrinkage is composed of elastic shrinkage and can be easily recovered while some of the change in dimensions may not be recovered, because the elastic limits of the fabric as constructed have been exceeded. Processing Shrinkage

- 20. Drying Shrinkage: Drying shrinkage is defined as dimensional change in a fabric when “deswelling” of fiber, yarn, and construction occurs in the drying step. The structure shrinks upon itself as a result of the physics of drying. This swelling and deswelling phenomena along with mechanical action is used in the AATCC Test Method 135-03. The test uses a washing machine to wet out (swell) the fiber/fabric under tensionless conditions and a tumble dryer to apply energy in the form of mechanical tumbling with heat to deswell and fully relax the fabric/garment. Tumble drying without restrictions (tension) is a form of mechanical compression and allows for maximum “drying shrinkage” to take place. The importance of the swelling mechanism is significant. As the fabric wets out without tension, swelling of the fibers and subsequently the yarns and the fabric results. Upon swelling, the crimp in the yarn loops increases. In effect, the loops in the knitted structure try to assume their lowest energy state that is a more round configuration, which is the lowest energy state for the yarn and therefore for the fabric. The rounding of the loop results in a shortening of the loop and therefore relaxation and dimensional change. Drying Shrinkage

- 21. Elastic Shrinkage: Elastic shrinkage is defined as a change in dimensions of a fabric as a result of the ability of the fabric to freely relax from tensions experienced during construction and other processing. In the case of cotton greige knit goods, tensions in forming the knitted loop, from the takedown and from spreader mechanisms on a knitting machine, are examples of stresses that may induce elastic shrinkage, which becomes a part of the construction shrinkage. The stress in transporting of fabric in bleaching and dyeing machines as well as finishing operations will also induce elastic shrinkage. Normally, the recovery from elastic stresses (realization of elastic shrinkage) is fairly spontaneous when these stresses are relieved, especially in a dry medium. It should be realized that because of these stresses during processing, the delivered dimensions that were measured for the greige fabrics are no longer applicable. The residual shrinkage has changed. In fact, the stresses involved may exceed the elastic limit and will prevent the finished fabrics from relaxing or bulking as much as the greige fabrics. Therefore, not only will the residual shrinkage be different, but also the relaxed dimensions of the processed fabrics will be different from the greige fabrics. Relaxed dimensions are defined as the state at which a fabric is fully relaxed and will not shrink further as a result of washing and tumble drying.Relaxed dimensions are also referred to as the reference state. Elastic Shrinkage

- 22. In today’s modern finishing plants, methods are used to attempt to overcome processing shrinkage and reduce construction shrinkage. These methods include relaxation drying, compaction, and/or chemical processes.Relaxation drying and compaction are examples of consolidation shrinkage. The former occurs naturally by deswelling of the cotton fiber/yarn assembly while applying unrestricted agitation with no tensions in the length or width. The latter is a dry mechanical effect gained by forcing the fabric structure to compact upon itself. The more processes of this type the mill can effectively apply along with linear forces removed from the processing, then the lower and more consistent the amount of shrinkage. Just as greige and finished dimensions can be measured, the dyer/finisher can also measure the effect of each processing step on fabric shrinkage. Benchmarks for measuring dimensional change can be applied on the greige goods and measured at each point along the processing route. By using this technique of process monitoring, the finisher may realize and correct for any avoidable distortion problems that may occur along the processing route. For example, if the extraction step is shown to stretch the fabric in the length by significant amounts, then the finisher can adjust the machinery to lower the forces applied in this process to thereby reduce the distortion and lower shrinkage.The initial reaction of most management teams is that they cannot afford to do this type of monitoring in their plant; however, in-plant process evaluation costs are offset by the money they save by reducing reworks for shrinkage and also by eliminating from consideration those constructions for processing that cannot meet customer specifications due to their unsuitability to the processing equipment in place. An example of the effect of processing tensions is discussed later in this bulletin.

- 23. Measurement of Fabric Shrinkage & Dimensional Stability

- 24. Shrinkage test: Testing time: After dryer or before compacting. Equipment used: Shrinkage board ,shrinkage scale, measurement tape, scissor, washing machine, detergent. Lengthwise shrinkage = (-ve) %. Lengthwise extension = (+ve) %. Test method : ISO 6330:2000. Shrinkage tolerance: ±5%. The fabric is cut according to the shrinkage board. Then the fabric is washed by washing m/c with PCLF for 60 min. at 40. Then the shrinkage% is determined by the shrinkage scale. Shrinkage Test:

- 25. Determination of dimensional change in washing and drying: International Standard ISO 5077 First edition- 1984-12-01 Principle: The specimen is conditioned in the specified standard atmosphere and measured before subjection to the appropriate washing and drying procedure. After drying and conditioning and measuring of the specimen, the changes in dimensions are calculated. Apparatus and reagents: Specified in ISO 3759 and in ISO 6330. Atmospheric Condition: The atmospheric conditions required for pre- conditioning and testing are specified in ISO 139. Shrinkage Test: Determination of dimensional change in washing and drying

- 26. Test specimens: 1. The selection, dimensions, marking and measuring of test specimens are specified in ISO 3759. 2. The number of specimens to be tested is determined by the precision of the results required. In this test method, it is suggested that four specimens of each sample be tested and these specimens be washed in two separate wash loads with two specimens per wash load. 3. In certain circumstances, it may be desirable not to test four specimen may be used. . Shrinkage Test: Test specimens

- 27. Working Procedure: The sample which is done shrinkage test, spread on table. Then a glass template put on sample fabric which is square size. There are six mark on glass template and distance between two mark is 35 cm. Marking the sample fabric by unchangeable marker. Then sample is sewn by hand sewing machine. Sample is ready for washing. Simple wash the fabric at 60˚c temp for 90 min. after washing the fabric is taken out. Dry the sample as per any of the method. It can either be Line Dry or Flat Dry or Tumble Dry. To find the dimensional change read the Shrinkage/Stretch on 3 points on the Wrap side and 3 points on Weft Side. Get the mean value of wrap-wise and weft wise readings to get the Accurate Shrinkage or Stretch. Working Procedure: Shrinkage Test

- 28. Procedure: 1. Determine the original length and width dimensions, as appropriate after the specimens have been pre –conditioned, conditioned and measured according to the procedure specified in ISO 3759 2. Wash and dry the specimens according to one of the procedures specified in ISO 6330, as agreed between the interested parties. 3. After washing and drying, condition and measure the specimens and calculate the dimensional change of the specimens according to the procedure specified in ISO 3759 Working Procedure: Shrinkage Test

- 29. Shrinkage Template & Scale is used for finding accurate Shrinkage in fabric and Garments. 1. Shrinkage Template & Scale also measures the dimensional changes in fabrics after laundering, dry cleaning etc. 2. Template and shrinkage scale made up of transparent polymer plate to apply standard pressure on test specimen.

- 30. Features of Shrinkage Template & Scale: 1. To determine directly the % dimensional change (shrinkage) in all types of fabrics. 2. Fine calibrated Shrinkage Template with 18" x 18" & 10" x 10" benchmarks length-wise & width-wise. 3. Two fine tipped black & yellow fabric markers are supplied for accurate marking on light & dark color fabrics. 4. Calibrated scale to evaluate shrinkage & stretch directly Up to 15%.

- 31. How Shrinkage Template & Scale works? 1. The marking template should be placed on the specimen to be tested, making sure that the fabric is in flat position before marking.

- 32. How Shrinkage Template & Scale works?

- 33. How Shrinkage Template & Scale works? 1. Hold the template firm, and carefully mark the fabric through the eight slots of the template, to ensure that it does not move

- 34. Washing : Now put the fabric in the washing machine or Dry Cleaning. Dry the sample as per any of the method. It can either be Line Dry or Flat Dry or Tumble Dry. Drying : Dry the sample as per any of the method. It can either be Line Dry or Flat Dry or Tumble Dry. Washing process: Method : ISO 6330 Detergent: suitable detergent (0.5%) on the weight of 1.8kg sample. Sample size: 62cm×62cm Marking area: 50cm×50cm Time: 45min Temperature: 400C Machine RPM: 1100

- 35. To find the dimensional change read the Shrinkage/Stretch on 3 points on the Wrap side and 3 points on Weft Side. Calculation for shrinkage percentage:

- 36. Shrinkage is determined as; Shrinkage % = (length of fabric before wash)-(length of fabric after wash))/ (length of fabric after wash) *100 Example, length of fabric before wash = 35 cm length of fabric after wash = 33 cm Now, Shrinkage % = {(35-33)/ 33} * 100 = 6% Here, Shrinkage is 6%. Normally shrinkage is acceptable less than 5%. But it can be change in case of buyer requirement. Calculation for shrinkage percentage:

- 37. Calculation for shrinkage percentage: Shrinkage percentage = (Lo-L1) ×100/Lo Where, Lo = the distance between the datum line before washing and L1 = the distance between datum lines after washing. Calculation for shrinkage percentage:

- 38. Expression of results: 1. Calculate the mean changes in dimensions in both the length and width directions accordance with the arrangement in ISO 3759 as follows: 1. Express the average dimensional changes to the nearest 0.5%. 2. State whether the dimension has decreased (shrinkage) by means of a minus sign (-) or increased (extension) by means of a plus sign (+). Expression of results:

- 39. Get the mean value of wrap-wise and weft wise readings to get the Accurate Shrinkage or Stretch. Shrinkage Test result

- 40. As already noted, shrinkage is a serious problem with knitted fabrics. Even a target shrinkage of 5% maximum in both length and width directions is difficult to achieve. Slit (open-width) fabrics are stentered with overfeed and without undue stretching, then often Sanforised to reduce potential shrinkage. Both open-width and tubular fabrics are dried on what is effectively a continuous open-width ‘tumbler’ dryer in which the fabric passes through the machine in a relaxed state on a continuous belt and air is blown from jets through the fabric. Both types of fabric can then be subjected to compacting in which the fabric is overfed and steamed. It is claimed that tubular, mercerised and compacted knitted fabric can have a shrinkage as low as 1%. Remedies : Shrinkage

- 41. Shrinkage Tolerance of Different Fabric: Fabric Type Length (%) Width (%) S/J -5.50 -5.50 Lycra S/J -6.00 -6.00 Single Lacoste -7.00 -7.00 Lycra Single Lacoste -7.00 -7.00 1X1 Rib -7.00 -7.00 Lycra 1X1 Rib -7.00 -7.00 2X2 Rib -8.00 -8.00 Lycra 2X2 Rib -8.00 -8.00 Interlock -7.00 -7.00 Terry Fleece -5.00 -5.00

- 42. FOR 100% COTTON PLAIN SINGLE JERSEY Effect of GSM on Shrinkage (Tumble Dry): Sample No. Shrinkage 120 GSM 130 GSM 140 GSM 160 GSM 180 GSM Length wise Width wise Length wise Width wise Length wise Width wise Length wise Width wise Length wise Width wise 01 -6.5% -5% -4.4% -5% -3.62 -1.96 -3.32 -2.18 -2.18 -2.08 02 -4.51% -4.16% -3.74 -2.09 -3.7 -0.96 -3.17 -2.5 -2.72 -2.13 03 -5.74 -2.41 -4.15 -4.9 -3.43 -6.06 -3.37 -2.33 -2.74 -2.17 04 -4.44 -3.92 -4.22 -3.37 -3.18 -4.12 -2.94 -2.29 -1.17 -2.19 05 -4.7 -6.12 -3.75 -0.99 -3.56 -4 -3.15 -2.2 -0.72 -2.03

- 43. Fig: Effect of GSM on Shrinkage in lengthwise (Tumble Dry)

- 44. METHODS FOR REDUCING SHRINKAGE Now that shrinkage has been defined, the factors that have an impact on performance will be looked at in detail. There are many factors that relate to shrinkage. These include the fiber, the yarn size and type, construction variables, wet processes, finishing procedures, apparel manufacturing techniques, and garment care methods. Cellulosic fibers are not as easily stabilized as are thermoplastic synthetics, because they cannot be heatset to attain stability. Also, synthetic fibers do not exhibit the swelling/deswelling scenario that cotton exhibits. However, the comfort and overall appeal of cotton has resulted in greater demand by the consumer and by usage in the textile industry. Therefore, the relaxation of fabrics made with cotton fibers requires either mechanical and/or chemical means for stabilization.

- 45. METHODS FOR REDUCING SHRINKAGE Yarns, of course, are made with fibers and exhibit the same characteristics as the fiber. Yet the manner these fibers are oriented in a yarn will affect certain properties of the fabric including shrinkage. Cotton singles yarns of high twist will usually yield higher shrinkage values than yarns of lower twist levels and will certainly yield greater skewing or torqueing. Rotor spun yarns do not typically yield significant different length shrinkage values than ring spun yarns, but are usually wider and certainly exhibit less fabric and garment torque. Plied yarns of either type usually yield very little skewing tendencies, but do not impact shrinkage. Different constructions can have significantly different shrinkage characteristics. For example, the performance of a single pique is certainly different from that of a jersey or interlock made from the same yarns and should be processed in a different manner. For example, the “tuck” stitches in a pique tend to make the fabric wider and less extensible than single jersey. Typically, pique fabrics have much higher length shrinkage than width shrinkage.

- 46. METHODS FOR REDUCING SHRINKAGE Wet processing procedures generally exhibit stress on a fabric. Continuous processes during dyeing and preparation for drying usually stretch the length and pull down or reduce the width, sometimes beyond their elastic limit thereby changing the relaxed dimensions. Finishing procedures may reduce or increase the dimensional stability of the fabric. If relaxation dryers, compactors, and/or crosslinking agents are used, then the residual shrinkage after wet processing can be reduced. Apparel manufacturing processes often increase the level of shrinkage in a fabric. The laying down of the layers for cutting and the physical manipulation of the panels in sewing are examples of where shrinkage values can be increased. In fact, garments comprised of different fabric constructions may have some panels relax with handling in cut-and-sew while other panels may grow. Garment care labeling and laundering practices will have a direct influence on shrinkage performance. If the label calls for line or flat drying, then mostly elastic shrinkage will affect performance. However, if tumble drying is suggested, then all available residual shrinkage will be realized.

- 47. METHODS FOR REDUCING SHRINKAGE The best chance to achieve low shrinkage in cotton knitted fabrics is to totally engineer the product from fiber selection through all processing steps. The parameters for success can be outlined as follows: 1. Proper product specifications and fabrication. 2. Low tensions during wet processing (dyeing and extraction). 3. Relaxation drying. 4. Finishing with compaction and/or crosslinking agents. 5. Low tension packaging for apparel manufacturing.

- 48. Low Tension Wet Processing Each step in wet processing applies some stress to a knitted fabric. Some processes require that the fabric be pulled continuously through a range or cycled through a vessel in order to get a desired effect. Jet dyeing machines, becks, bleaching ranges, and pad and beam processing units all pull on the fabric in the length direction during the process. Equipment manufactured today applies less stress on the fabric than did those of only ten years ago; however, it is common for these machines to stretch fabrics in the length. At the same time, some soft flow and overflow jet dyeing machines actually either do not stretch the fabric or may even relax the goods in the length. Unless it is restrained, the width of a knit fabric will relax upon wetting out in all these vessels as a result of the tensions on the fabric in the length. In this respect, a knit fabric acts like an accordion. The extraction process is the single greatest area of concern for length distortion in wet processing for knit fabrics. Strides have been made in recent years to reduce the amount of fabric stretch in extraction; however, length stretch of 10% and higher is commonplace. Low Tension Wet Processing

- 49. Relaxation Drying Relaxation dryers are available in conveyor belt systems, suction drum units, combinations of both, and continuous tumblers. All systems make use of mechanical action during drying to provide the energy to yield lower shrinkage. In order for a knit fabric to shrink during drying, certain criteria must take place. The methods used to shrink the fabric must be able to overcome the static friction that exists within the loops of the knitted structure. Key factors for relaxation drying should include: 1. Releasing of all tensions from the fabric, especially its own weight and that of any water it might contain at the entry of and in the dryer. 2. The use of softeners to aid fabric structure mobility by reducing the static friction at yarn intersections. 3. Mechanical action either by air flow and belt vibration. 4. Sufficient and uniform mechanical action to overpower all static friction within the structure but at levels low enough to prevent stretching. 5. A uniform air flow in intensity, varied in direction, but not offsetting in application. 6. Necessity to either spread the fabrics with overfeed at the entry of the dryer or to spread at a station just before the dryer. 7. Maintaining sufficient overfeed in all drying zones to allow for complete mobility in the fabric length during deswelling. 8. Tension free precision plaiting of the fabric for apparel manufacturing or for the next processing step.

- 50. Compaction During compaction, static friction is overcome by physical force. Compaction is the use of compressive forces to shorten the fabric to reduce the length shrinkage. This is achieved by heated roll and shoe compactors or compressive belt systems to force the length of the loop in a knit to become not only shorter, but also more round in configuration thereby resulting in lower length shrinkage values. This process is a consolidation process resulting in “consolidation shrinkage.” Softener selection has a big impact on the efficiency of the compactor. The use of improper softeners can prevent the compaction force from being effective by causing slippage between fabric surfaces and machine components in the shrinking zone. Softeners may also reduce the static friction so much that the yarn loops may easily compact, but then lose the compaction during subsequent processing. Corrugation or wrinkling of the surface because of improper loop movement during compaction can be a big problem to finishers. This is a defect usually associated with over-compaction, but it can also be caused by improper or non-uniform softener application as well as improper moisture content at the compactor.

- 51. Chemical Finishing Chemical crosslinking has been the most used method for stabilizing cotton knit apparel fabrics especially those finished in open-width form. Compaction methods have also been effective but have been mainly used on underwear fabrics and most tubular goods. The advent of wet processes that impose lower tensions on fabric, such as the evolution of relaxation dryers and the improvement of compaction machinery including open-width, have combined to reduce the need for or level of chemical finishing.However, the desire for very low shrinkage without the corresponding increase in bulk experienced with compaction of a knit structure has led to the continued use of crosslinking agents for cotton products. Chemical crosslinking affects the swelling of cotton and reduces shrinkage by altering the normal shrinking (swelling/deswelling) phenomena. In fact, a well-designed crosslinking system will permanently alter the shrinkage thereby altering the relaxed dimensions. Other benefits of a chemical finish would be a better appearance as related to wrinkling after washing and tumble drying, less tendency to pill or form surface fuzz from repeated laundering, and improved color retention for some dyestuffs. The disadvantages are losses of strength and shorter wear life.

- 52. The importance of understanding shrinkage and it causes is key to its control. In summary, a partnership between a mill and an apparel firm is a necessity for success in the marketplace. This is true whether the product is a national or store brand at retail. Mutual planning and engineering of a product is the only recipe for success. In order to meet product specifications, the correct yarn, machine set-up, and dyeing and finishing processes must be chosen. Arbitrary specifications and improper choices of processing routes are a guarantee for failure in the battle to control shrinkage for cotton fabrics. CONCLUSIONS

- 53. Reference : A GUIDE TO IMPROVED SHRINKAGE PERFORMANCE OF COTTON FABRICS ISP 1009 © 2004 Cotton Incorporated. All rights reserved; America’s Cotton Producers and Importers. Class lectures of Textile Physics and Textile Testing and quality Control , Southeast university, Fall - 2013 .