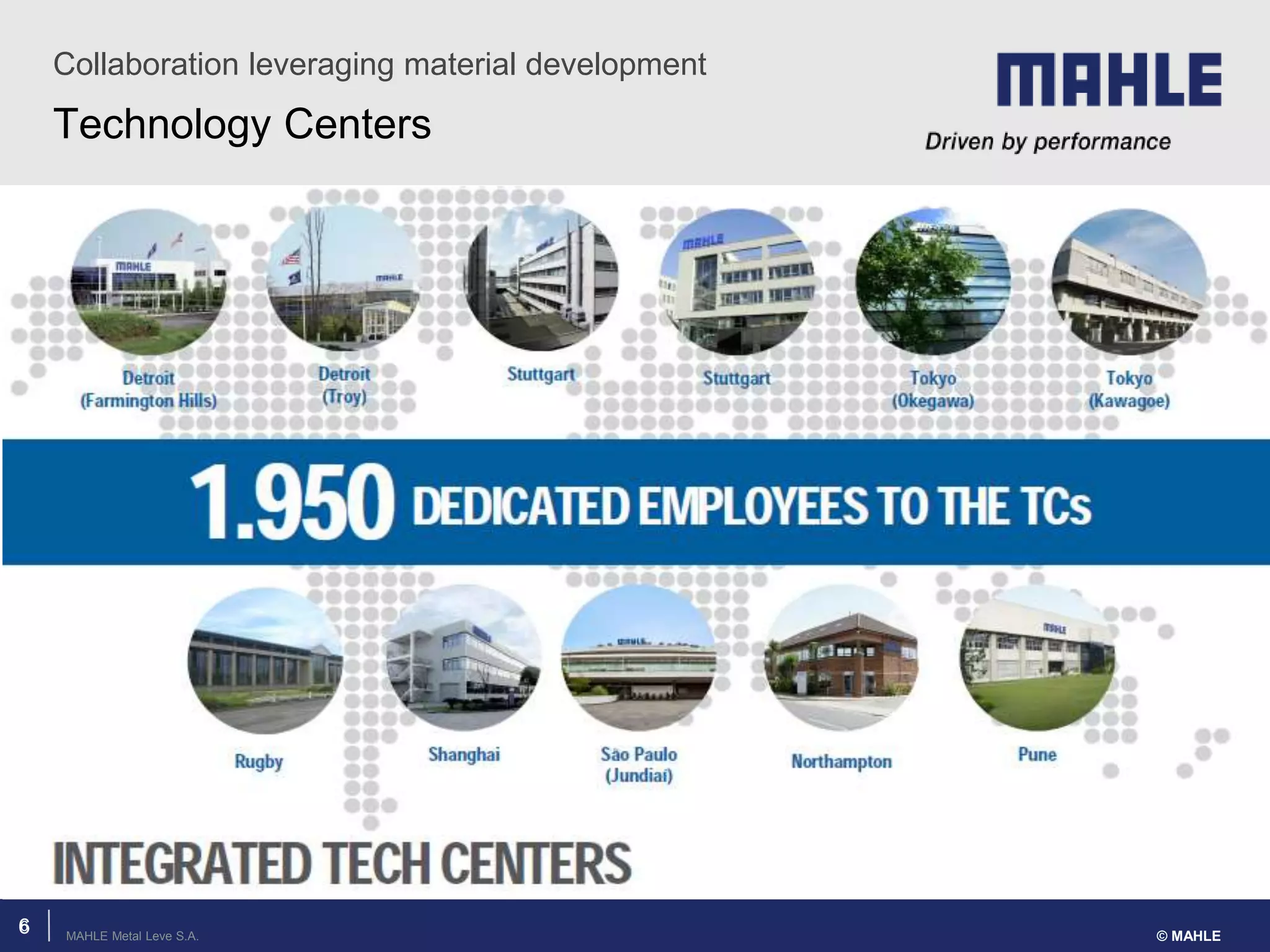

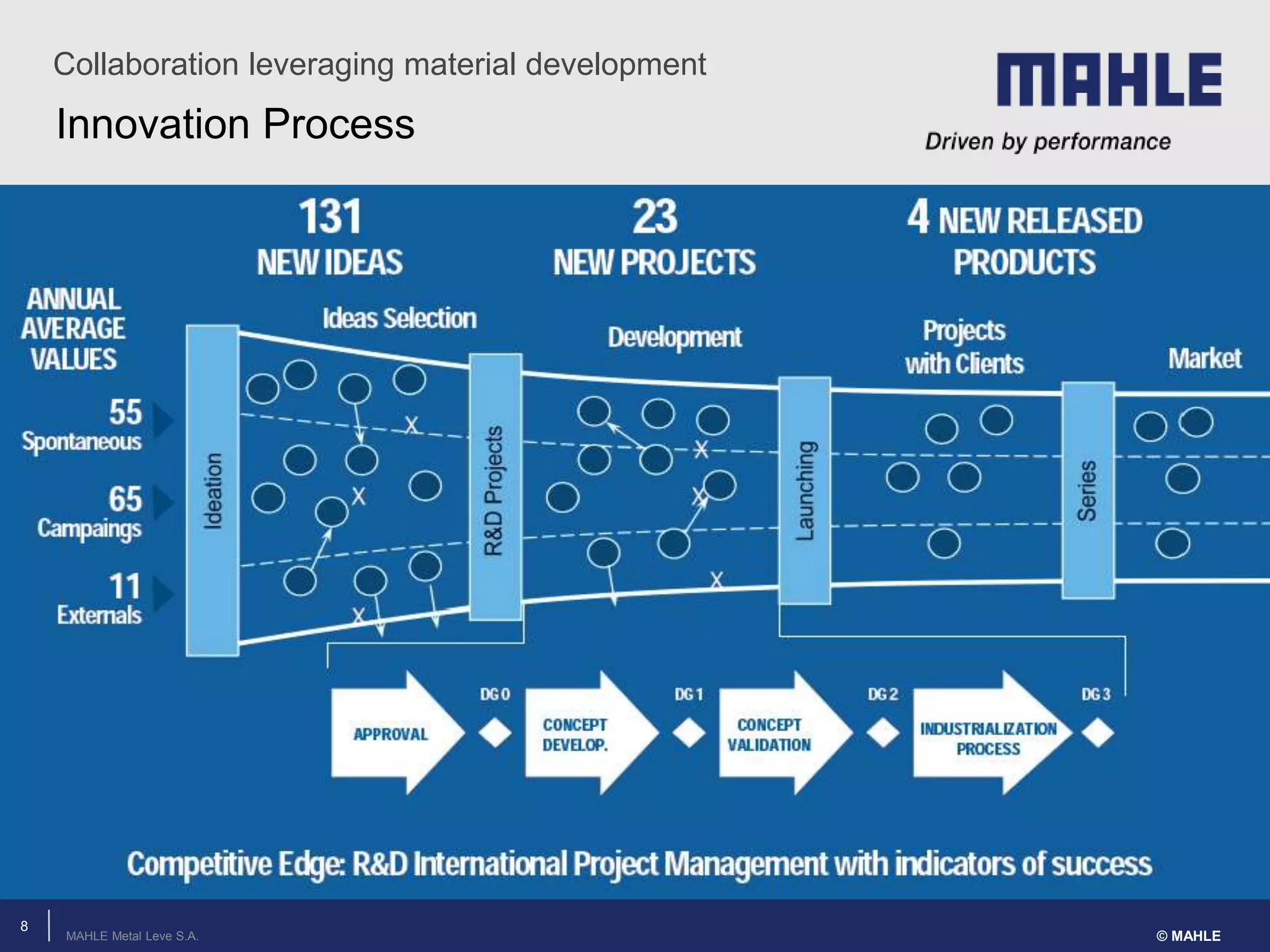

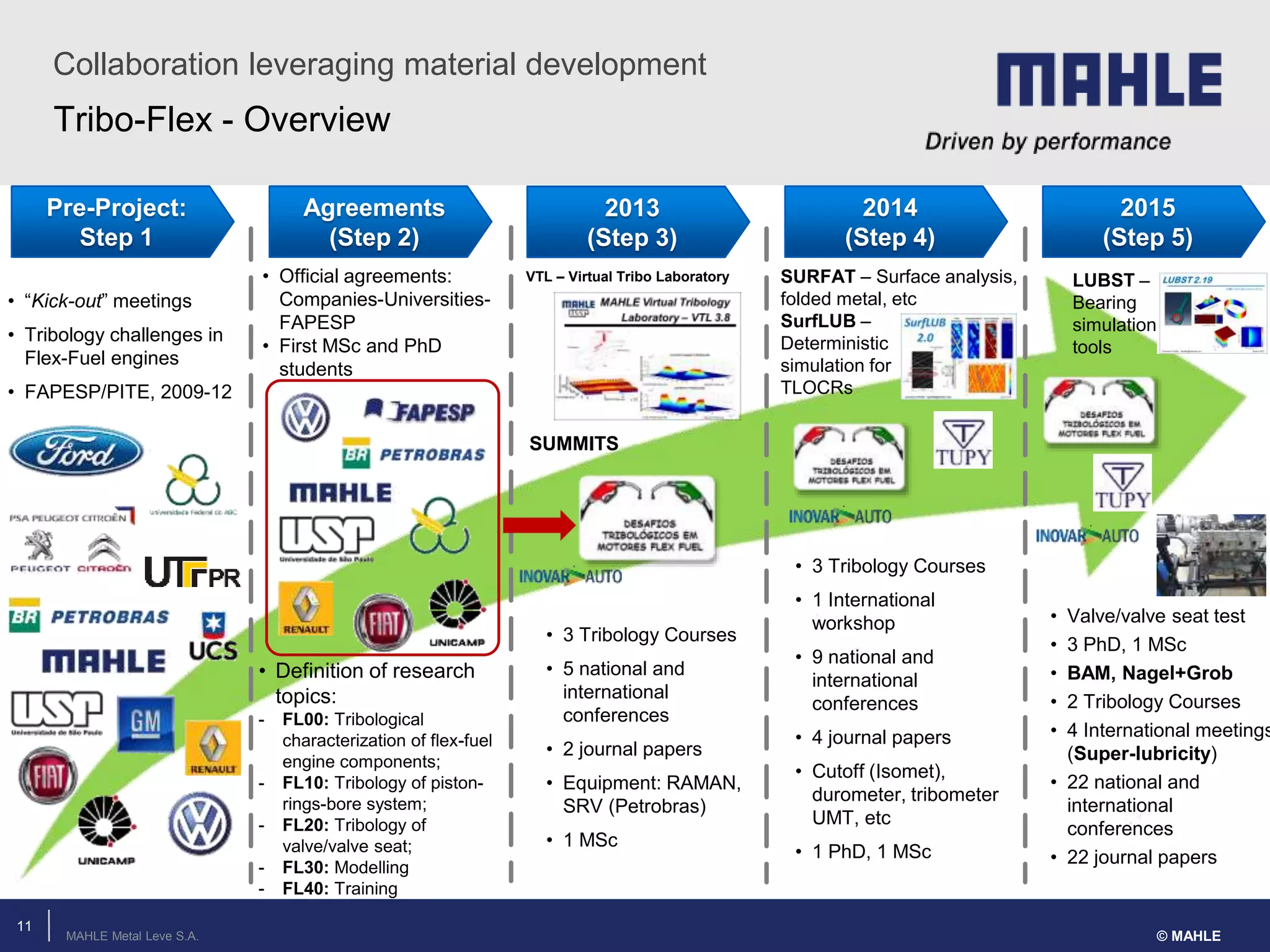

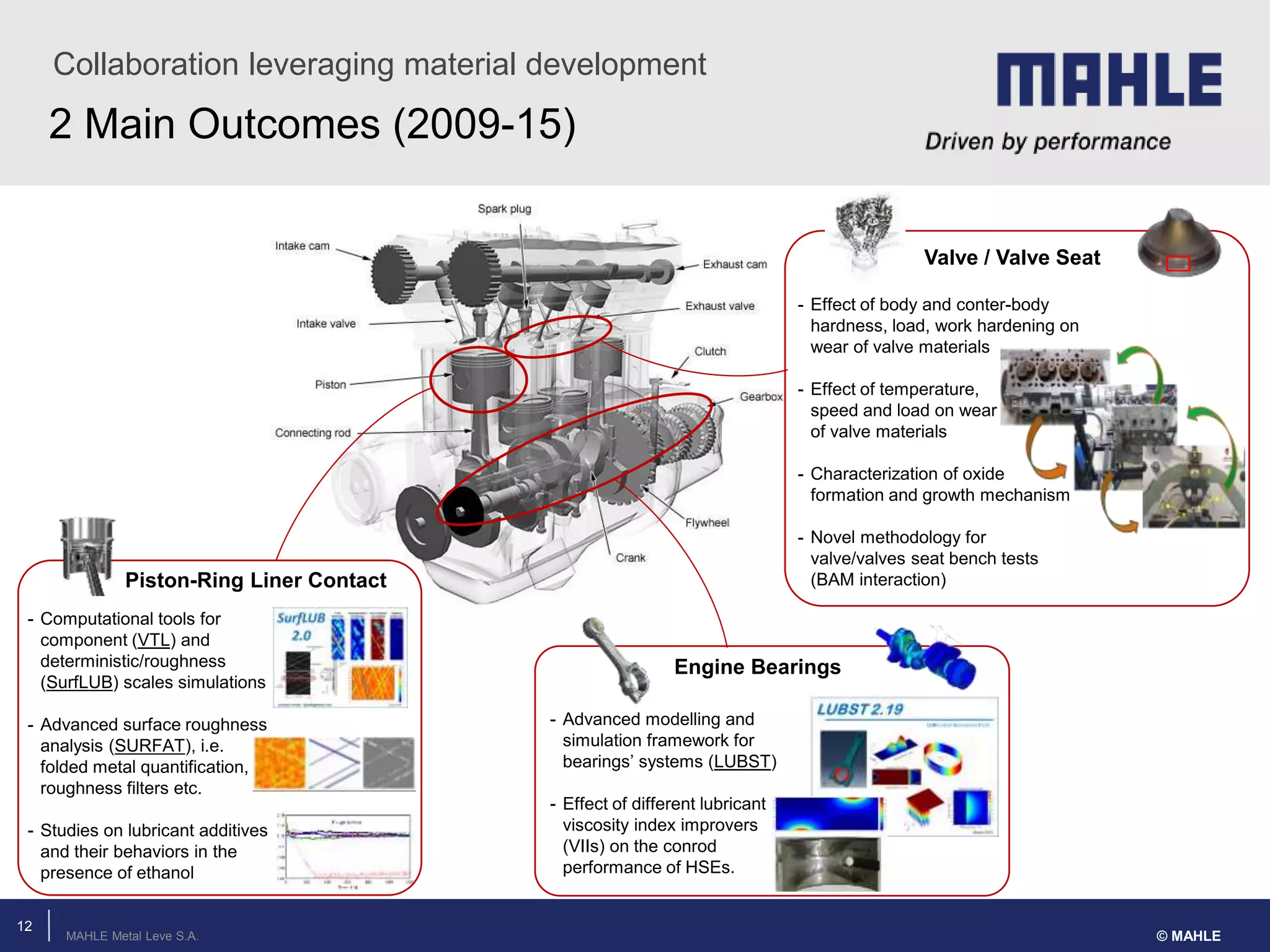

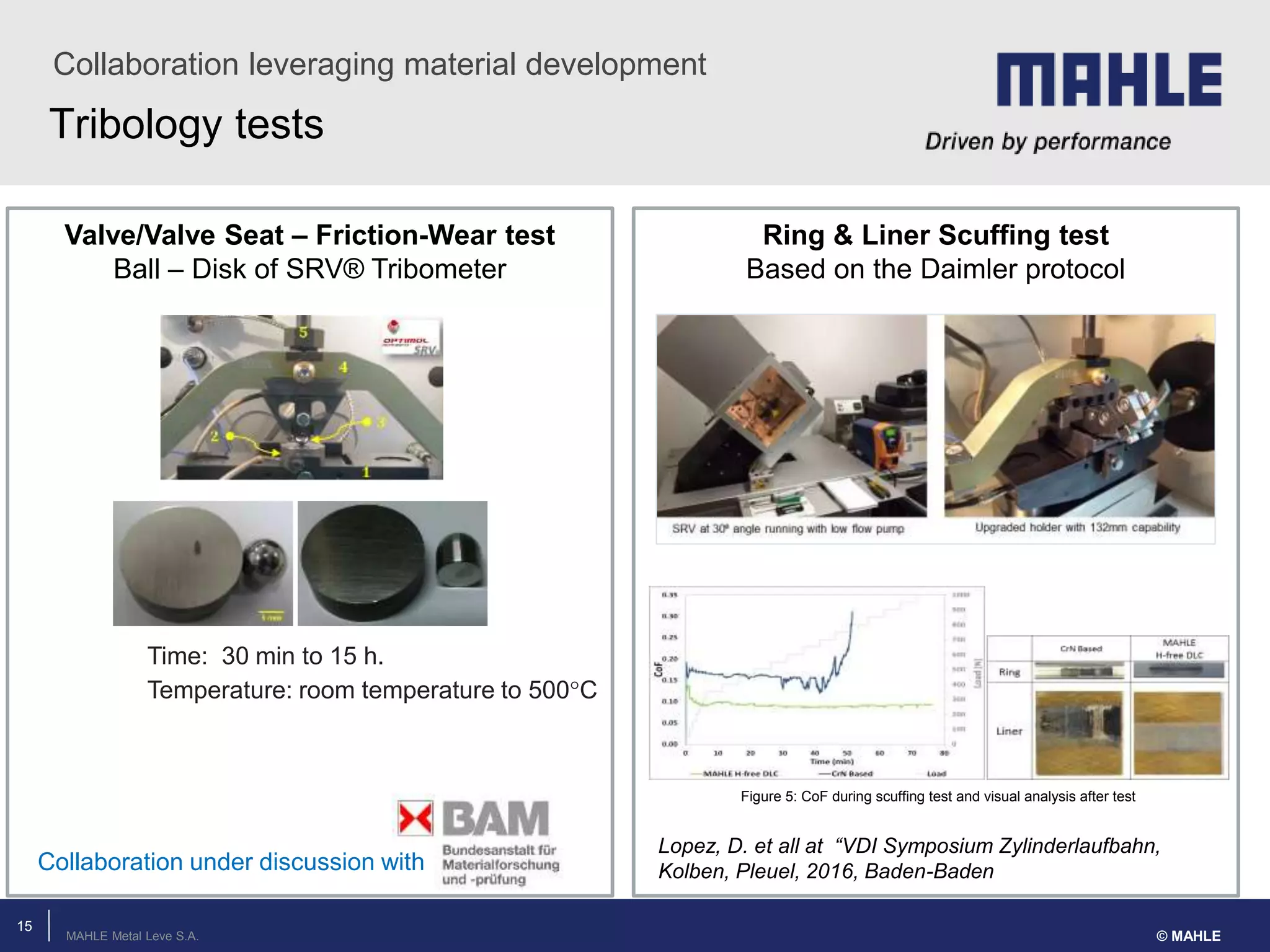

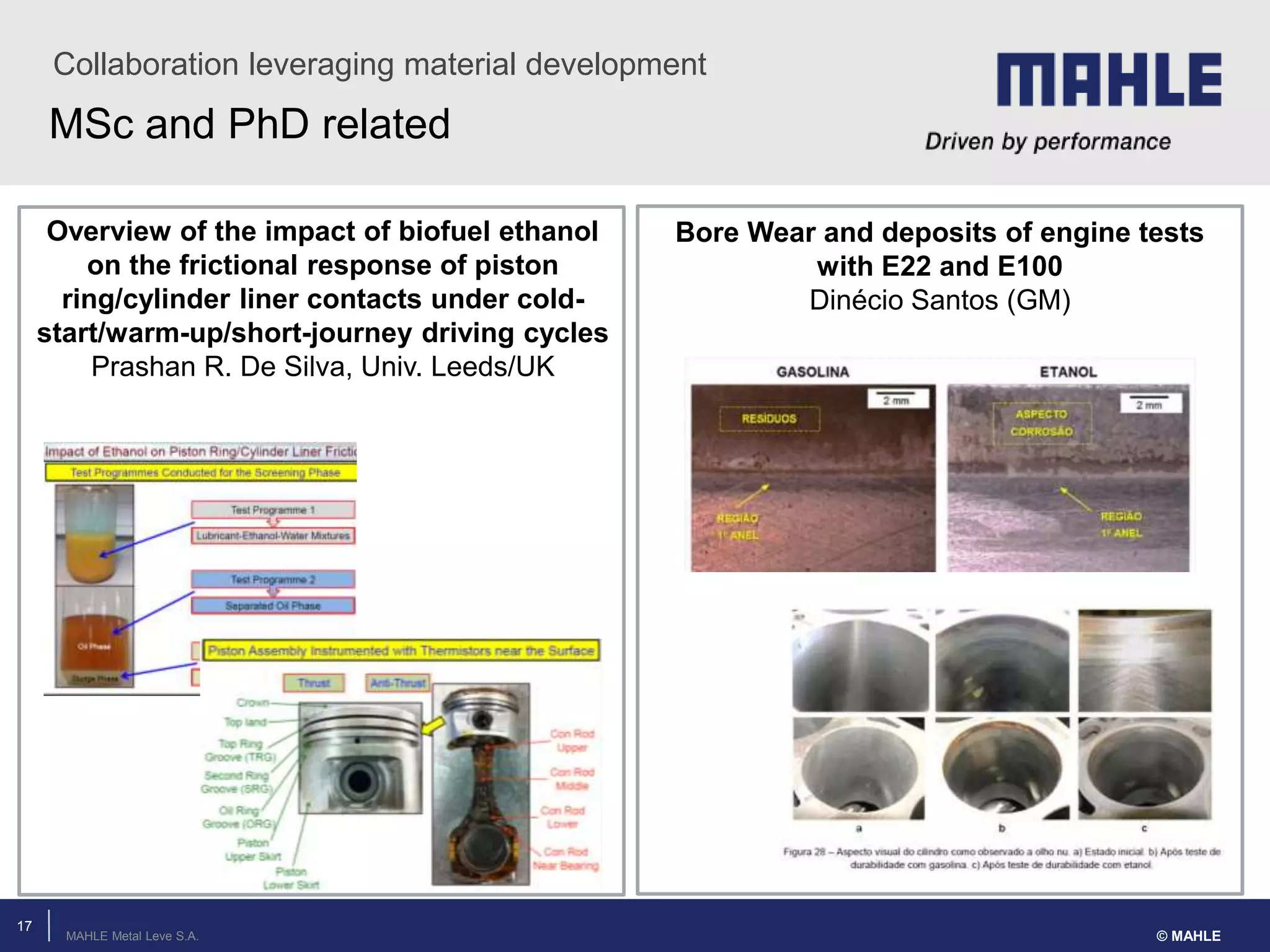

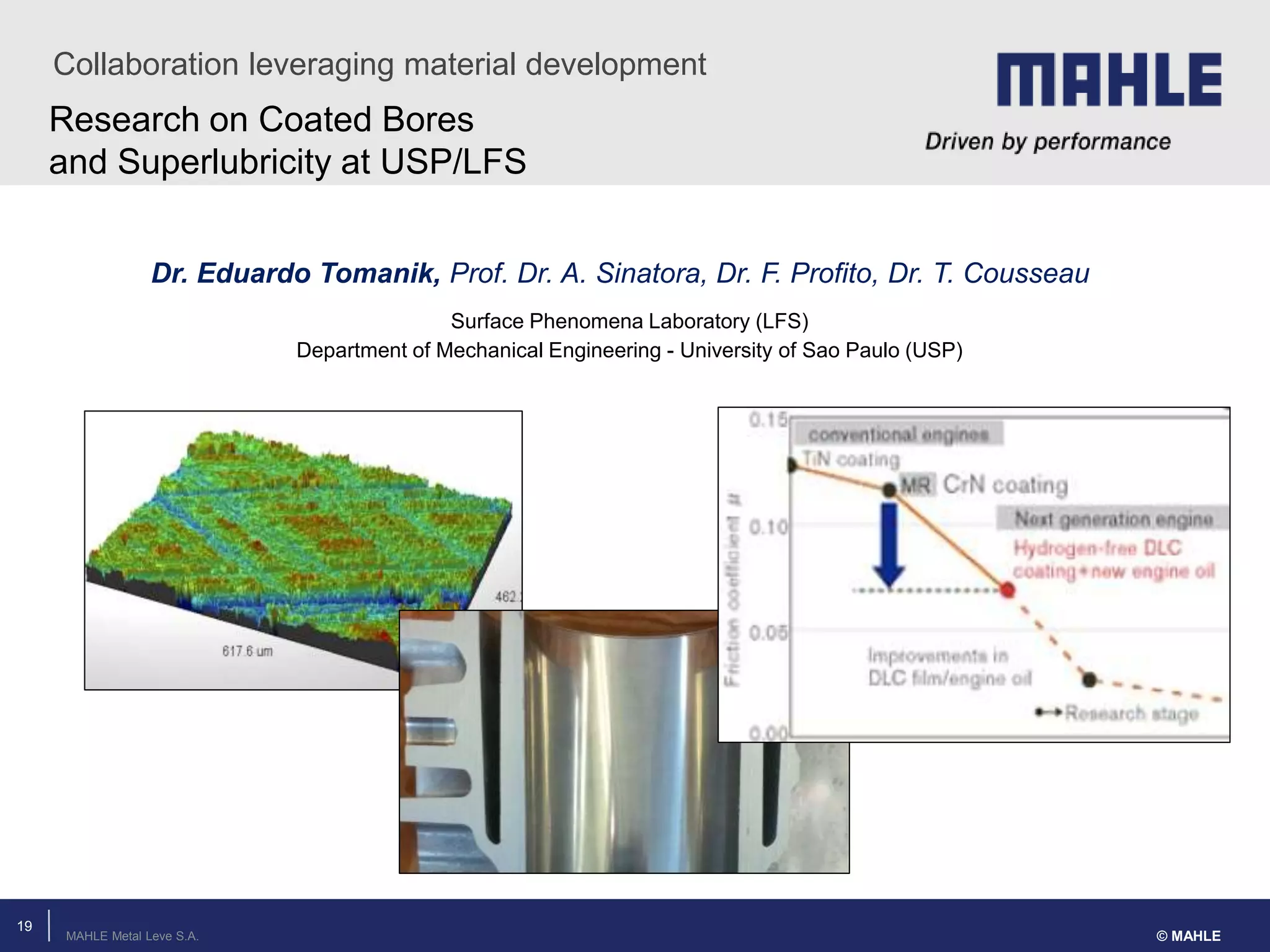

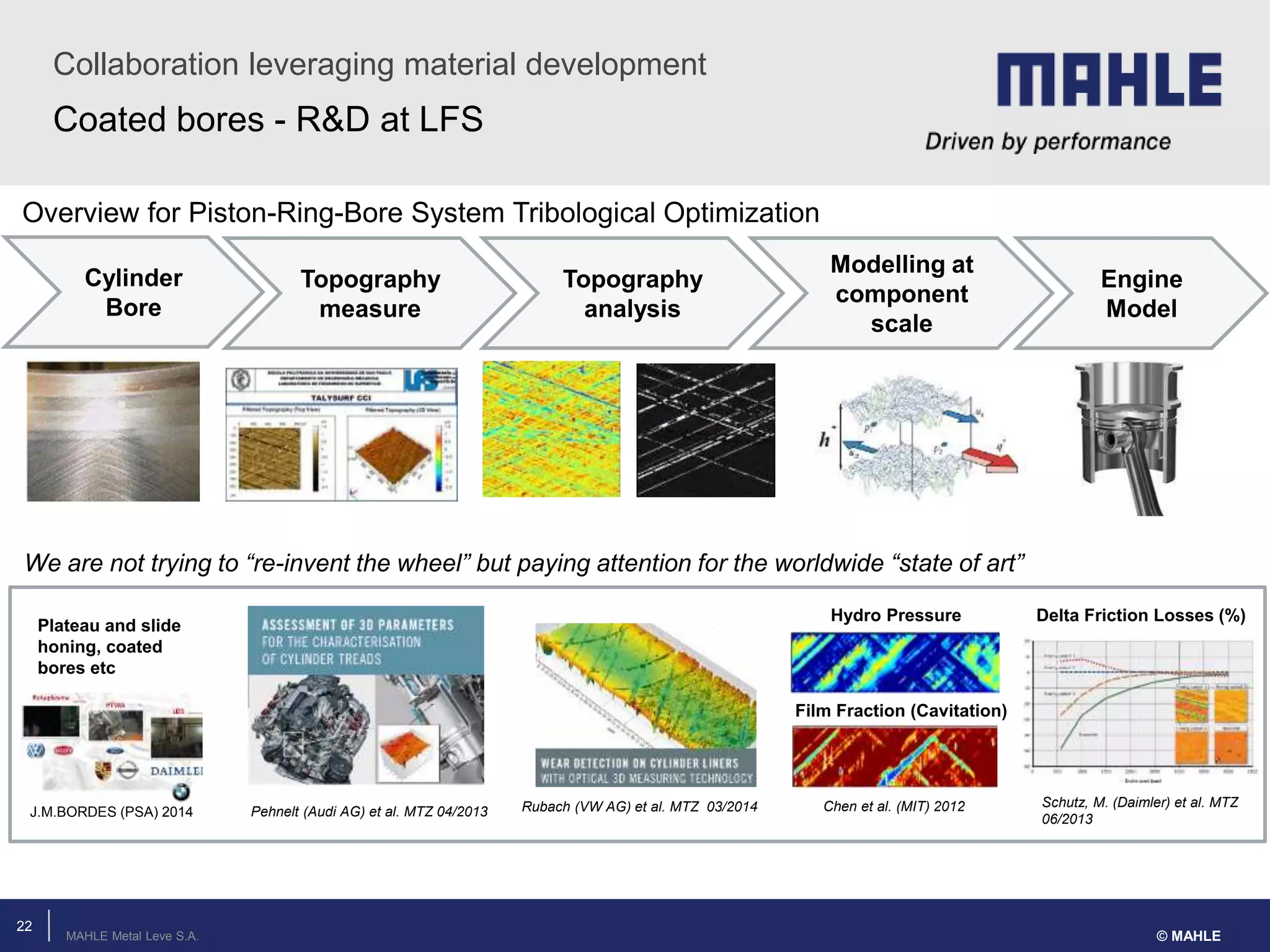

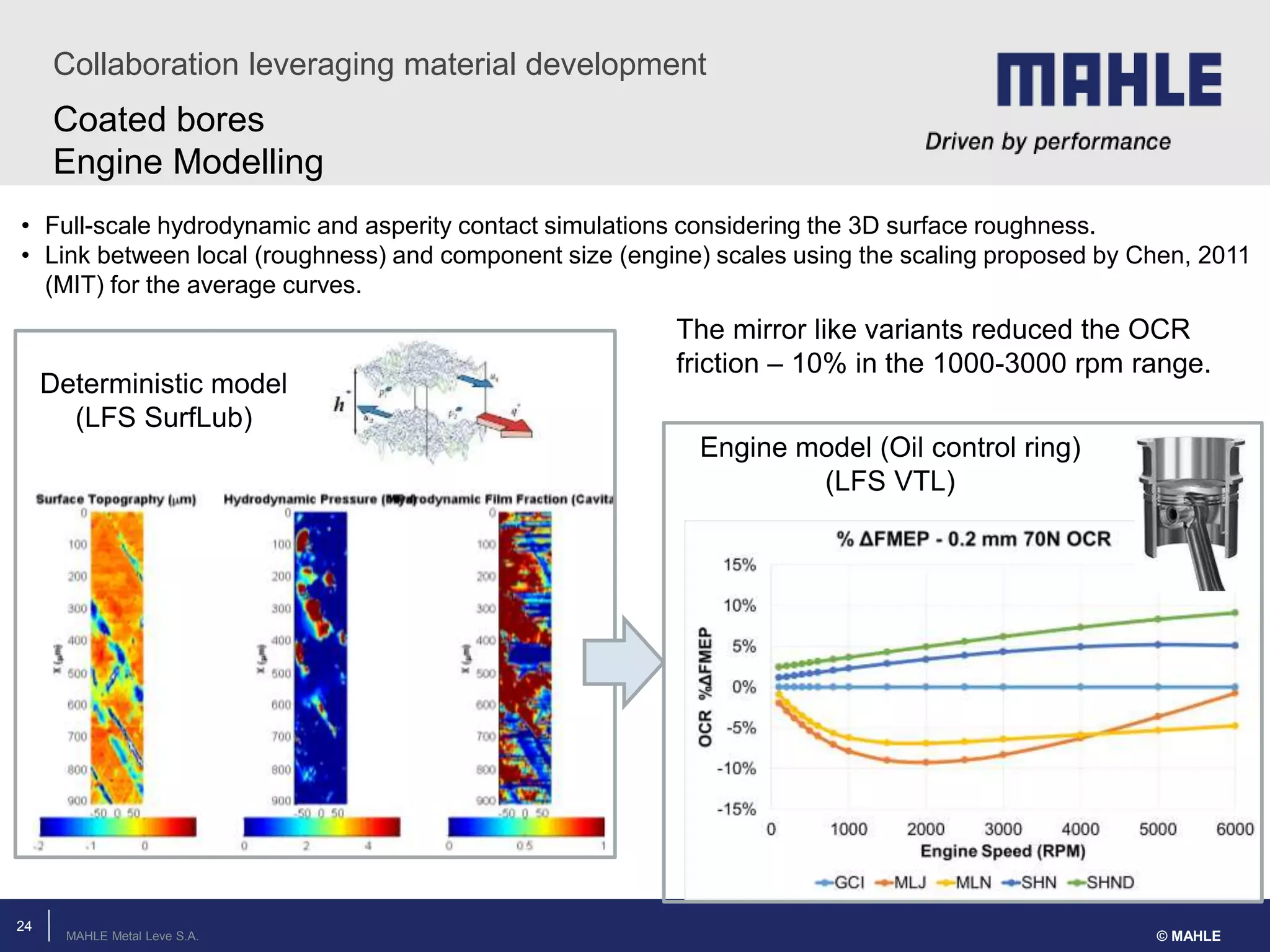

The document discusses Mahle's collaboration in material development, particularly in tribology related to flex-fuel engine components and coated bores. It highlights various research initiatives, their outcomes, and partnerships with universities and companies, emphasizing the importance of collaboration in achieving advancements in technology. Key findings include the impact of lubricants on engine performance and the potential of superlubricity to significantly reduce friction in automotive applications.