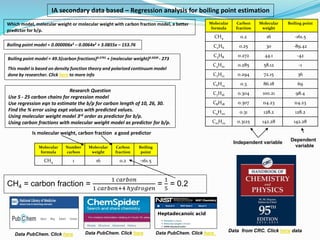

IA data based, boiling point estimation using molecular model vs carbon fraction with molecular weight model

- 1. Which model, molecular weight or molecular weight with carbon fraction model, a better predictor for b/p. Independent variable Dependent variable Data from CRC. Click here data IA secondary data based – Regression analysis for boiling point estimation Boiling point model = 49.5(carbon fractions)0.2791 + (molecular weight)0.5039 - 273 This model is based on density function theory and polarized continuum model done by researcher. Click here to more info Research Question Use 5 - 25 carbon chains for regression model Use regression eqn to estimate the b/p for carbon length of 10, 26, 30. Find the % error using expt values with predicted values. Using molecular weight model 3rd order as predictor for b/p. Using carbon fractions with molecular weight model as predictor for b/p. Molecular formula Carbon fraction Molecular weight Boiling point CH4 0.2 16 -161.5 C2H6 0.25 30 -89.42 C3H8 0.272 44.1 -42 C4H10 0.285 58.12 -1 C5H12 0.294 72.15 36 C6H14 0.3 86.18 69 C7H16 0.304 100.21 98.4 C8H18 0.307 114.23 114.23 C9H20 0.31 128.2 128.2 C10H22 0.3125 142.28 142.28 Data PubChem. Click here Data PubChem. Click here Data PubChem. Click here Boiling point model = 0.000006x3 – 0.0064x2 + 3.0855x – 153.76 Molecular formula Number carbon Molecular weight Carbon fraction Boiling point CH4 1 16 0.2 -161.5 CH4 = carbon fraction = 1 𝑐𝑎𝑟𝑏𝑜𝑛 1 𝑐𝑎𝑟𝑏𝑜𝑛+4 ℎ𝑦𝑑𝑟𝑜𝑔𝑒𝑛 = 1 5 = 0.2 Is molecular weight, carbon fraction a good predictor

- 2. Class Functional group/name Examples alkene C = C Alkenyl ethene alkyne C ≡ C Alkynyl ethyne alcohol OH Hydroxyl ethanol ether C – O - C Ether methoxymethane ketone O ‖ C – C - C Carbonyl propanone aldehyde CHO Aldehyde ethanal Carboxylic acid COOH Carboxyl ethanoic acid ester O ‖ C – O -R Ester ethyl ethanoate amide O ‖ C – NH2 Amide propanamide amine NH2 Amine ethanamine nitrile C ≡ N Nitrile propanenitrile Class Functional gp Suffix Example Formula Alkane C - C - ane ethane CnH2n+2 Homologous Series carbon IUPAC name Structure formula Molecular formula Boiling point 1 Methane CH4 CH4 Gas 2 Ethane CH3CH3 C2H6 Gas 3 Propane CH3CH2CH3 C3H8 Gas 4 Butane CH3(CH2)2CH3 C4H10 Gas 5 Pentane CH3(CH2)3CH3 C5H12 Liquid 6 Hexane CH3(CH2)4CH3 C6H14 Liquid Physical properties • Increase RMM / molecular size •RMM increase ↑ - Van Der Waals forces stronger ↑ ↓ Melting /boiling point increases ↑ (Increasing polarisability ↑) London dispersion forces/temporary dipole ↑ 1 2 3 4 5 6 7 8 9 10 number carbons – RMM ↑ 150 100 50 0 -50 -100 -150 -200 b/p increase ↑ boiling point room temp gas liquid Homologous Series number Carbons / RMM ↑ 1 2 3 4 5 6 7 8 9 10 boiling point boiling point increase with increase carbon atoms alcohol alkane alkene alkyne London dispersion force (temporary dipole) H2 bonding carboxylic acid > alkane/alkene/alkyne alcohol carboxylic acid

- 3. Number carbon Molecular weight b/p predicted b/p using model 1 2 3 4 5 72.15 36 6 86.18 69 7 100.21 98.4 8 114.23 125.6 9 128.2 151 10 142.28 174.1 11 156.31 196 12 170.33 216.2 13 184.37 234 14 198.39 253.6 15 212.42 270.6 16 226.41 286.9 17 240.4 302 18 254.5 317 19 268.5 330 20 282.5 343 21 296.6 363 22 310.6 368 23 324.6 379 24 338.6 391 25 352.7 403 IA secondary data based –Regression analysis for boiling point estimation Research Question Use 5 - 25 carbon chains for regression model Use regression eqn to estimate the b/p for carbon length of 10, 26, 30 Find the % error using expt values with predicted values. Using molecular weight model 3rd order as predictor for b/p. Using carbon fraction with molecular weight model, as predictor for b/p. Molecular weight 3rd order as predictor for b/p Number carbon Molecular weight Carbon fraction b/p predicted b/p using model 1 2 3 4 5 72.15 0.294 36 6 86.18 0.3 69 7 100.21 0.304 98.4 8 114.23 0.307 125.6 9 128.2 0.31 151 10 142.28 0.3125 174.1 11 156.31 0.314 196 12 170.33 0.315 216.2 13 184.37 0.317 234 14 198.39 0.318 253.6 15 212.42 0.319 270.6 16 226.41 0.32 286.9 17 240.4 0.3207 302 18 254.5 0.3214 317 19 268.5 0.322 330 20 282.5 0.3225 343 21 296.6 0.323 363 22 310.6 0.3235 368 23 324.6 0.3239 379 24 338.6 0.3243 391 25 352.7 0.3246 403 Carbon fraction and molecular weight as predictor for b/p Independent variable Independent variable Dependent variable Dependent variable

- 4. Predicted b/p for carbon 10 – MW of 142.3 3rd order fit, y = 0.000006x3 – 0.0064x2 + 3.0855x – 153.76 b/p=0.000006(142.3)3 – 0.0064(142.3)2 + 3.0855(142.3) – 153.76 = 173 Research Question Which model, molecular weight model, 3rd order, better predictor for b/p. Which model, molecular weight and carbon fraction model, better predictor for b/p. y = 6E-06x3 - 0.0064x2 + 3.0855x - 153.76 R² = 0.9998 0 50 100 150 200 250 300 350 400 450 0 50 100 150 200 250 300 350 400 b/p molecular weight molecular weight vs b/p Predicted b/p carbon 10 – using model CF – 0.3125, MW – 142.28 y = 49.5(carbon fractions)0.2791 x (molecular weight)0.5039 - 273 b/p=49.5(0.3125)0.2791 x (142.28)0.5039 -273 = 162 Predicted b/p for carbon 26 – MW of 366.7 3rd order fit, y = 0.000006x3 – 0.0064x2 + 3.0855x – 153.76 b/p=0.000006(366.7)3 – 0.0064(366.7)2 + 3.0855(366.7) – 153.76 = 413 Predicted b/p for carbon 30 – MW of 422.8 3rd order fit, y = 0.000006x3 – 0.0064x2 + 3.0855x – 153.76 b/p=0.000006(422.8)3 – 0.0064(422.8)2 + 3.0855(422.8) – 153.76 = 460 Molecular weight 3rd order as estimator for b/p Molecular weight and carbon fraction as predictor for b/p Boiling pt model = 49.5(carbon fractions)0.2791 x (molecular weight)0.5039 -273 This model is based on density function theory and polarized continuum model done by researcher. Click here to more info Number carbon Molecular weight Carbon fraction b/p predicted b/p using model 10 142.28 0.3125 174.1 162 26 366.7 0.325 412 435 30 422.8 0.326 449.7 489 Predicted b/p carbon 26 – using model CF – 0.325, MW – 366.7 y = 49.5(carbon fractions)0.2791 x (molecular weight)0.5039 -273 b/p=49.5(0.325)0.2791 x (366.7)0.5039 - 273 = 435 Predicted b/p carbon 30 – using model CF – 0.326, MW – 422.8 y = 49.5(carbon fractions)0.2791 x (molecular weight)0.5039 -273 b/p=49.5(0.326)0.2791 x (422.8)0.5039 -273 = 489

- 5. Molecular weight 3rd order as predictor for b/p Molecular weight and carbon fraction model predictor for b/p Number carbon Molecular weight b/p predicted poly fit 3rd order (% error) 1 2 3 4 5 72.15 36 6 86.18 69 7 100.21 98.4 8 114.23 125.6 9 128.2 151 10 142.28 174.1 173 (0.5%) 11 156.31 196 12 170.33 216.2 13 184.37 234 14 198.39 253.6 15 212.42 270.6 16 226.41 286.9 17 240.4 302 18 254.5 317 19 268.5 330 20 282.5 343 21 296.6 363 22 310.6 368 23 324.6 379 24 338.6 391 25 352.7 403 26 366.7 412 413 (0.2%) 27 378.8 422 28 392.7 431 29 406.8 440 30 422.8 449.7 460 (2%) Number carbon Boiling point predicted (% error) 1 2 3 4 5 36 6 69 7 98.4 8 125.6 9 151 10 174.1 162 (7%) 11 196 12 216.2 13 234 14 253.6 15 270.6 16 286.9 17 302 18 317 19 330 20 343 21 363 22 368 23 379 24 391 25 403 26 412 435 (5.5%) 27 422 28 431 29 440 30 449.7 489 (8.7%) % error = (𝑬𝒙𝒑𝒕 𝒗𝒂𝒍𝒖𝒆 −𝑷𝒓𝒆𝒅𝒊𝒄𝒕𝒆𝒅 𝒗𝒂𝒍𝒖𝒆) 𝑬𝒙𝒑𝒕 𝒗𝒂𝒍𝒖𝒆 x 100% % error = (𝟏𝟕𝟒.𝟏 −𝟏𝟕𝟑) 𝟏𝟕𝟒.𝟏 x 100% = 0.5% % error = (𝑬𝒙𝒑𝒕 𝒗𝒂𝒍𝒖𝒆 −𝑷𝒓𝒆𝒅𝒊𝒄𝒕𝒆𝒅 𝒗𝒂𝒍𝒖𝒆) 𝑬𝒙𝒑𝒕 𝒗𝒂𝒍𝒖𝒆 x 100% % error = (𝟏𝟕𝟒.𝟏 −𝟏𝟔𝟐) 𝟏𝟕𝟒.𝟏 x 100% = 7%

- 6. Molecular weight and carbon fraction model is a weaker fit Molecular weight model is a better fit % error, smaller compared to the other model % error increases as molecular weight increases 3rd order fit – % error changes from 0.5% to 0.2% to 2% as carbon chain changes from 10 to 26 to 30 y = 6E-06x3 - 0.0064x2 + 3.0855x - 153.76 R² = 0.9998 0 50 100 150 200 250 300 350 400 450 0 50 100 150 200 250 300 350 400 b/p molecular weight molecular weight vs b/p Number carbon Molecular weight b/p predicted poly fit 3rd order (% error) 10 142.28 174.1 173 (0.5%) 26 366.7 412 413 (0.2%) 30 422.8 449.7 460 (2%) % error, bigger compared to molecular weight model. % error increases as carbon chains increases % error changes from 7% to 5.5% to 8.7% as carbon chain changes from 10 to 26 to 30 Research Question Which model, molecular weight model, 3rd order, better predictor for b/p. Which model, molecular weight and carbon fraction model, better predictor for b/p. Boiling pt model = 49.5(carbon fractions)0.2791 x (molecular weight)0.5039 -273 This model is based on density function theory and polarized continuum model done by researcher. Click here to more info Number carbon Molecular weight Carbon fraction b/p predicted (% error) 10 14228 0.3125 174.1 162 (7%) 26 366.7 0.325 412 435 (5.5%) 30 422.8 0.326 449.7 489 (8.7%)