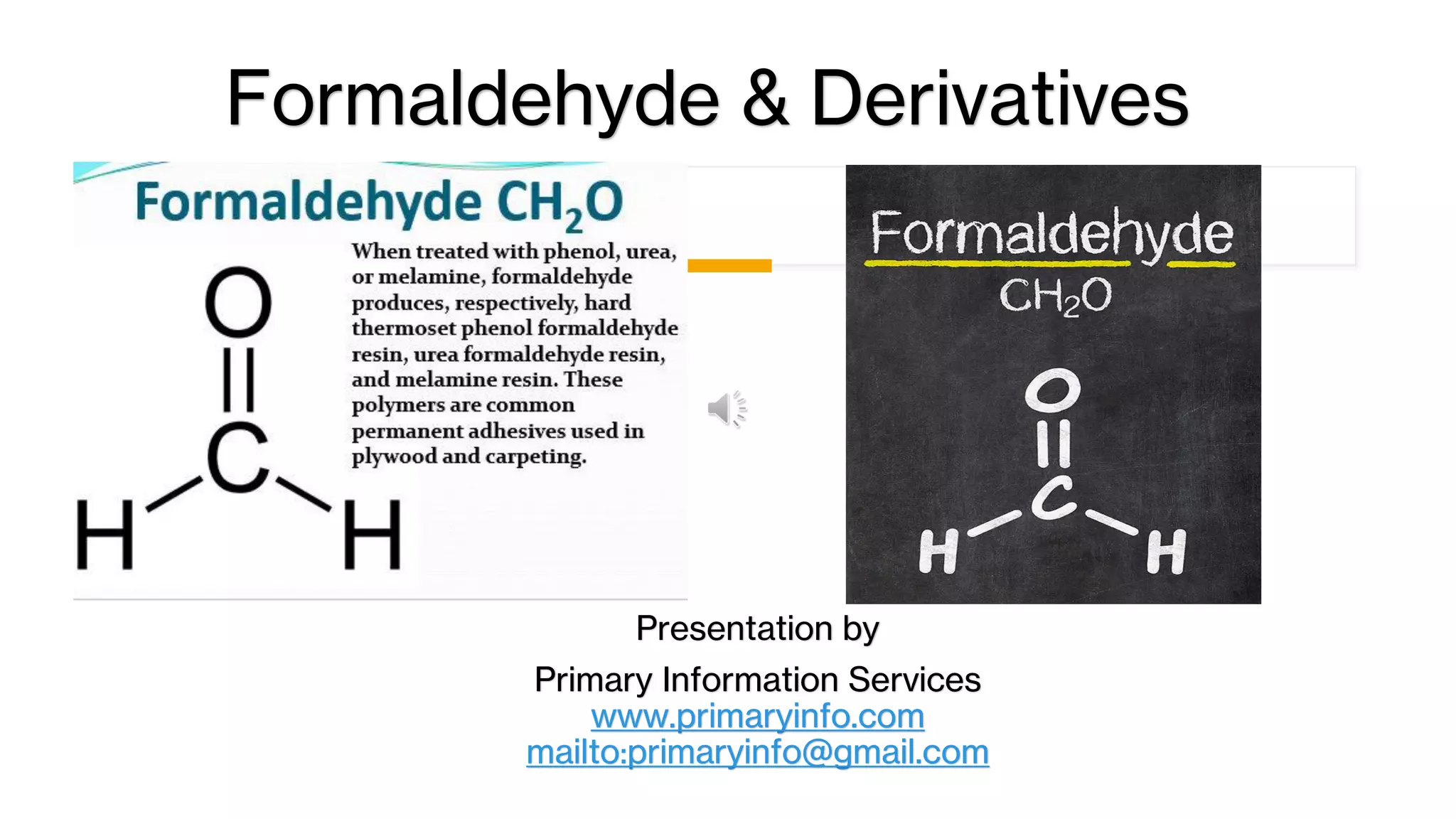

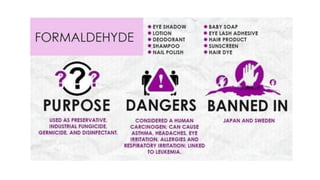

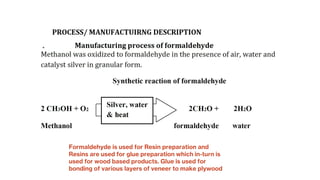

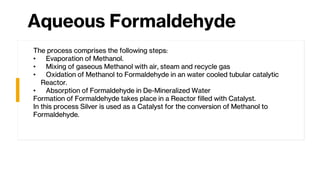

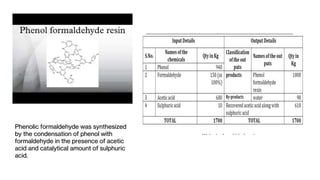

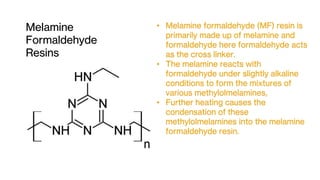

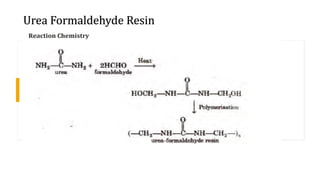

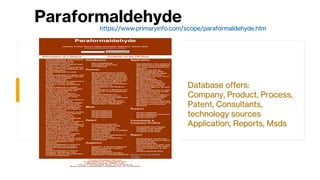

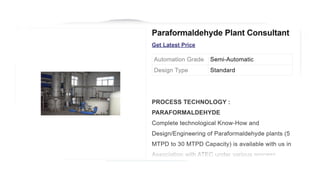

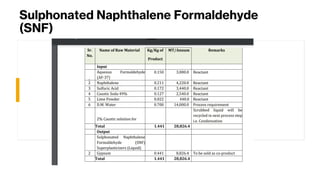

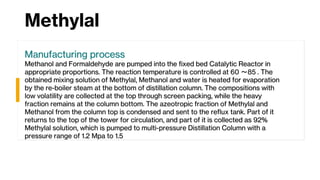

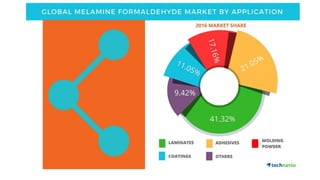

This document provides information on formaldehyde and its derivatives from Primary Information Services. It summarizes various manufacturing processes for formaldehyde and formaldehyde-based resins. It also advertises Primary Information Services' databases covering topics like aqueous formaldehyde production, melamine formaldehyde resins, methylal, dicyandiamide formaldehyde, and more. Contact information is provided for inquiries.