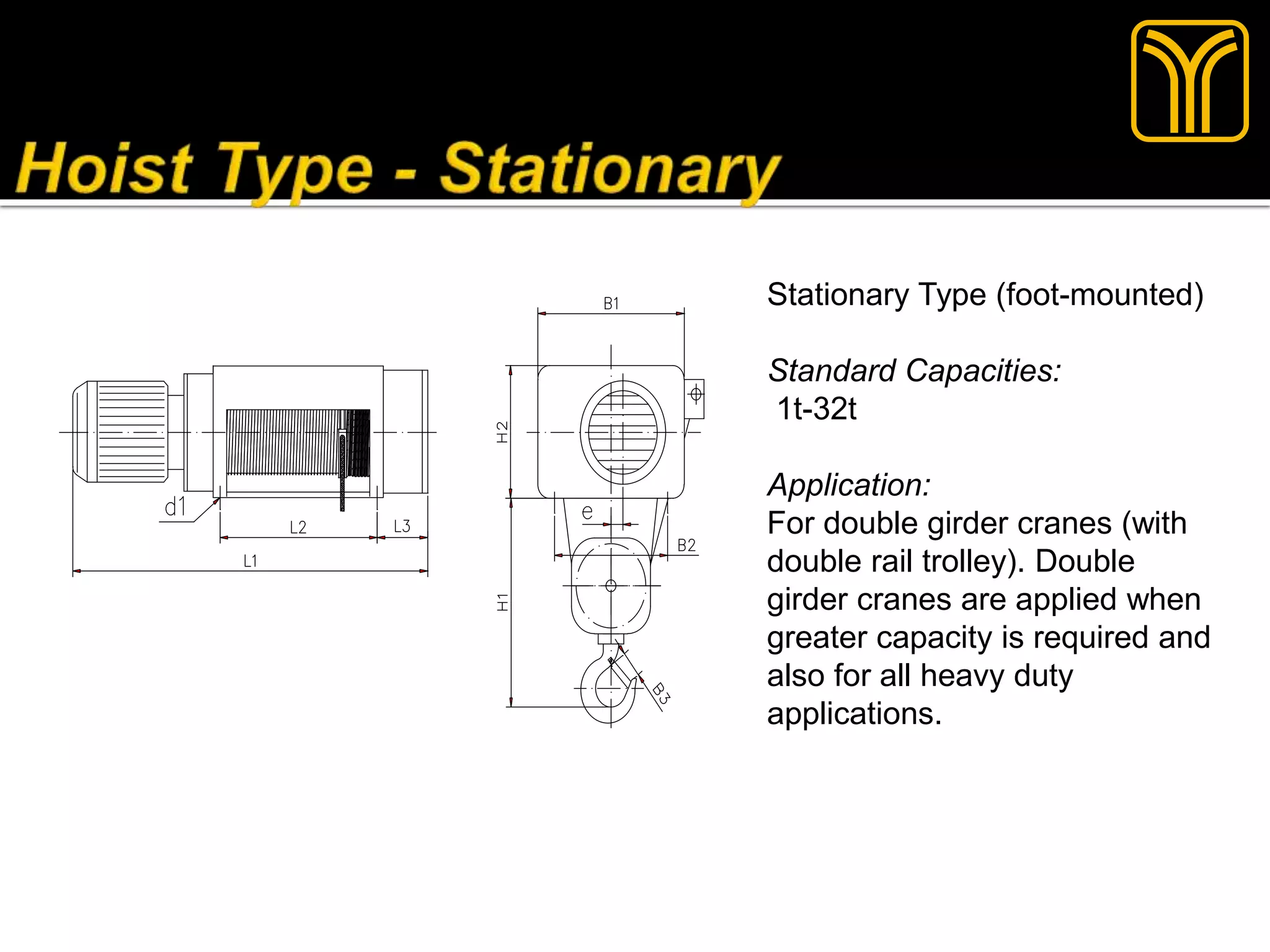

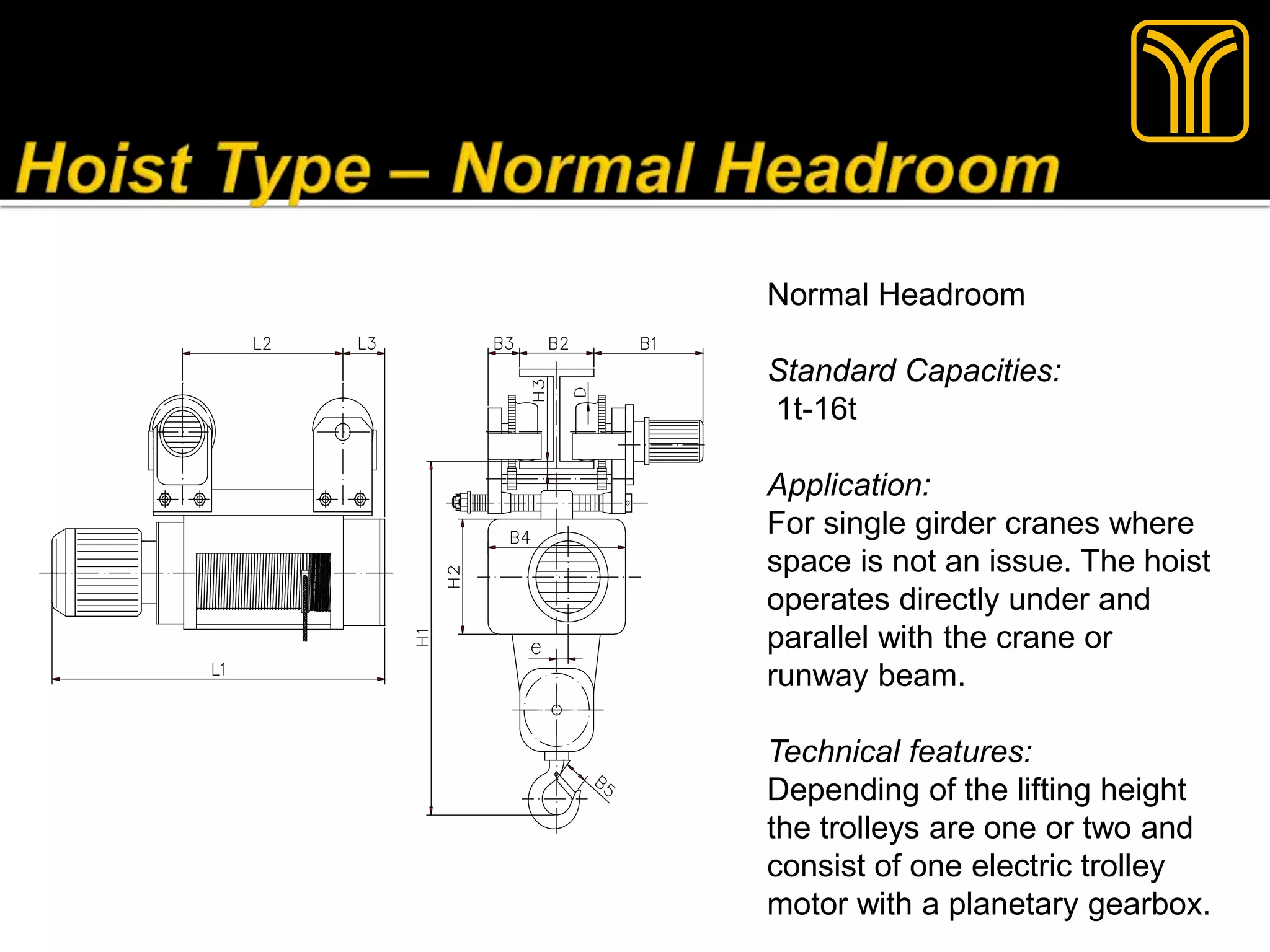

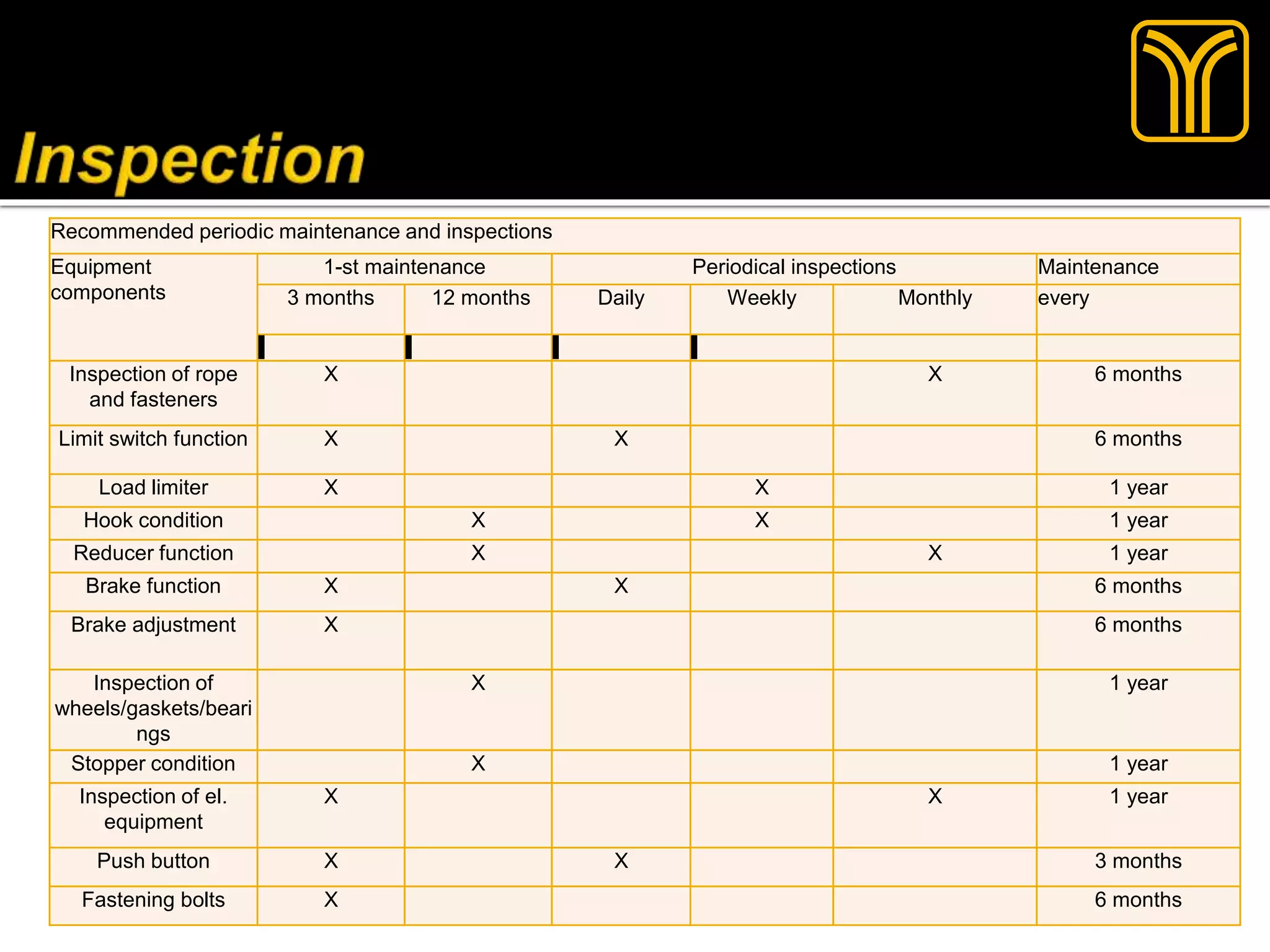

This document discusses electric wire rope hoists and crane components offered by MW Yantra including: hoists from 0.5 to 32 tons capacity in stationary, normal headroom, and low headroom versions. Technical details are provided on double rail trolley models KK10, KK20, and KK32 with capacities from 5 to 32 tons and lifting heights from 6.3 to 25 meters. The document also outlines standard operating conditions, recommended maintenance schedules, and contact information.