This document summarizes the requirements and procedures for a welder qualification test (WQT) at Doosan Heavy Industries & Construction. The summary includes:

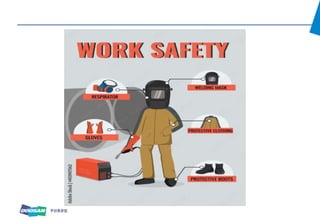

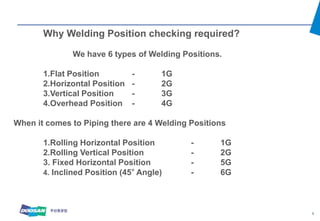

1. The WQT will test the welder's ability in various areas like power supply, welding machine, cables, holders, safety equipment, welding processes, materials, and positions.

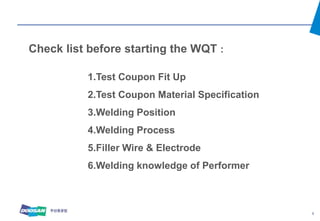

2. Proper preparation is required including fitting the test coupon, verifying material specifications, selecting the correct filler wire/electrode based on material, and checking welding parameters.

3. The performer's welding knowledge will be assessed through an interview to ensure they understand the welding process, parameters, materials, and safety requirements.