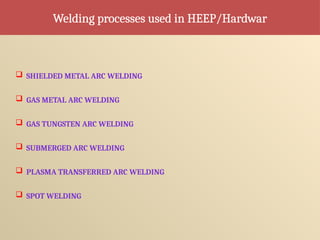

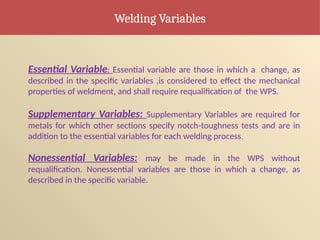

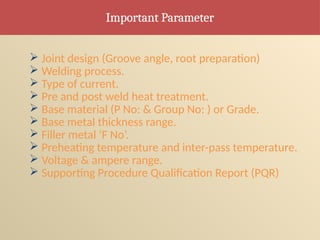

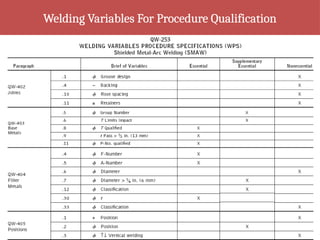

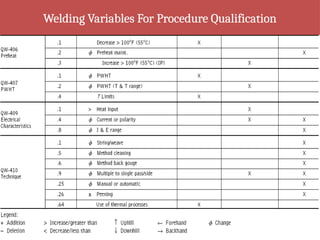

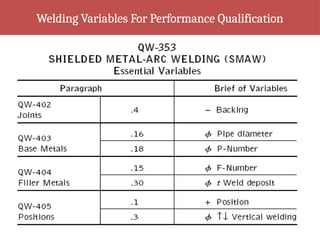

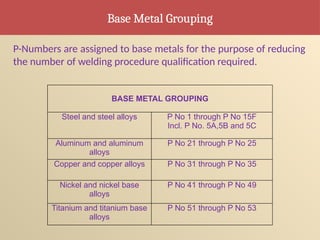

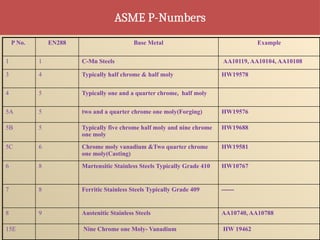

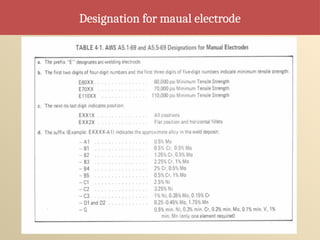

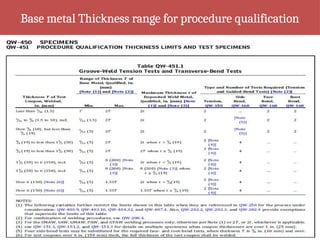

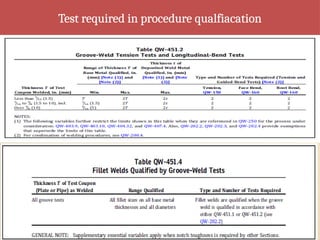

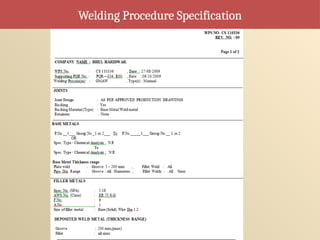

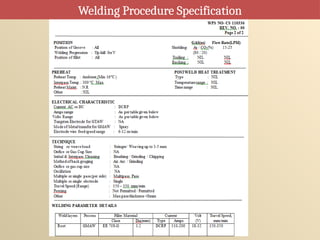

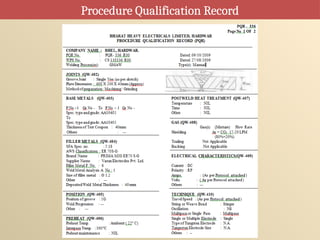

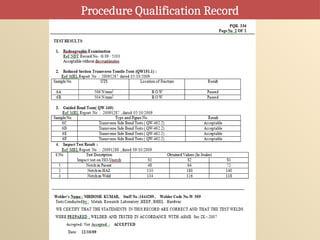

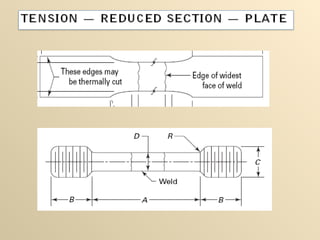

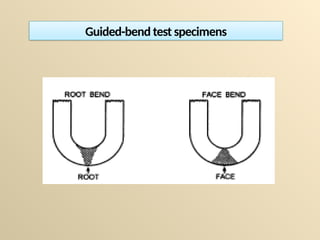

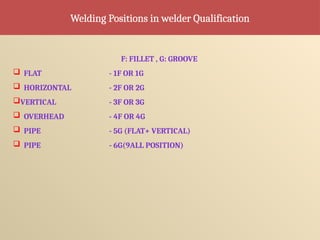

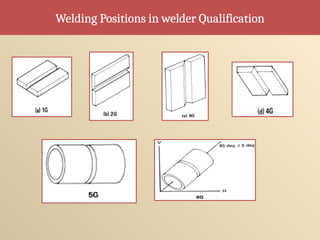

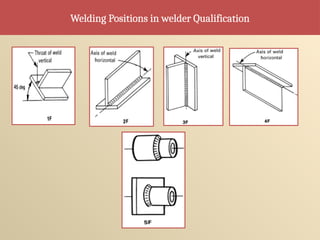

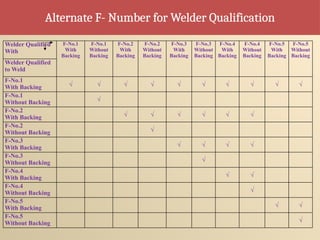

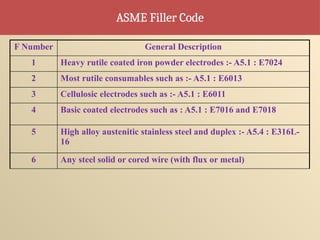

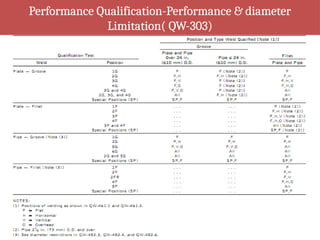

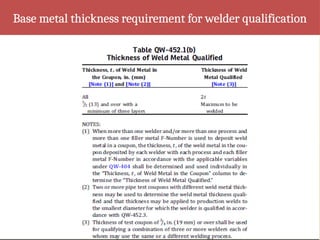

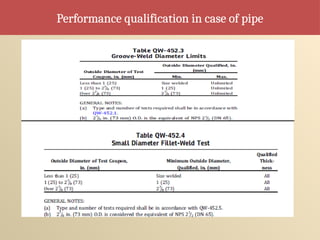

The document outlines the processes and qualifications related to welding engineering, specifically focusing on the development of welding procedures and welder qualifications based on shop requirements. It details various welding processes, essential and supplementary variables, and p-number groupings for different base metals to standardize procedure qualifications. Additionally, it covers welder performance qualifications through specific welding positions and filler metal classifications.