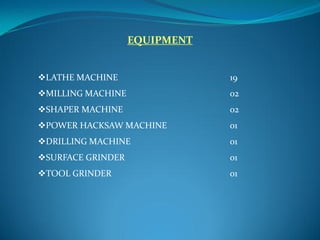

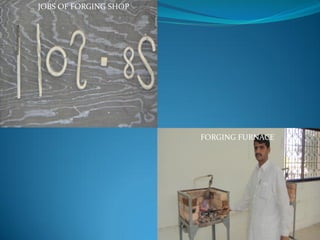

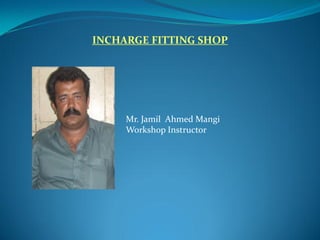

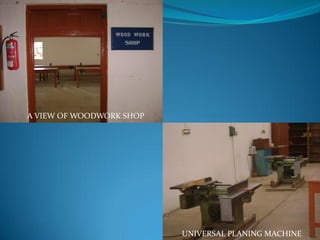

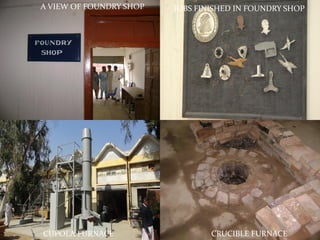

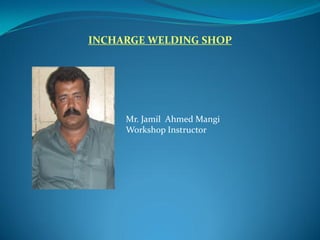

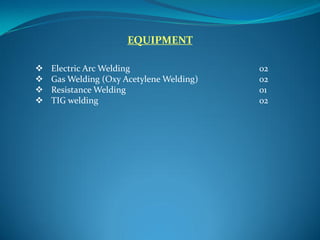

This document provides an overview of the Mechanical Engineering Workshop which includes several shops: machine shop, CNC shop, forging shop, fitting shop, wood work shop, foundry shop, and welding shop. It describes the purpose and key equipment of each shop area. The machine shop contains various lathes, mills, shapers, and other metalworking machines. The CNC shop utilizes computer-controlled machines for complex manufacturing. Staff and their roles are also outlined for the overall workshop and its individual sections.