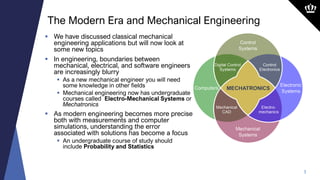

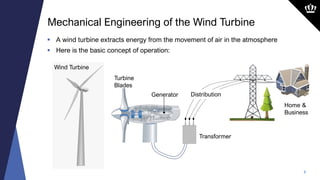

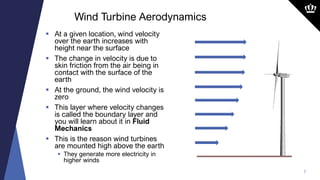

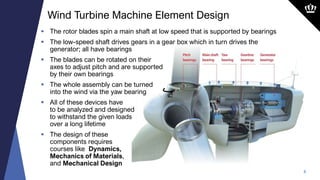

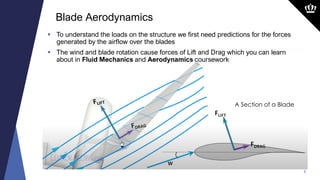

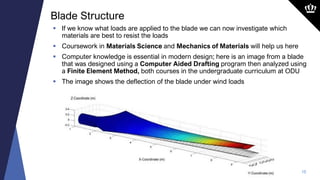

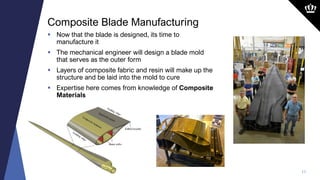

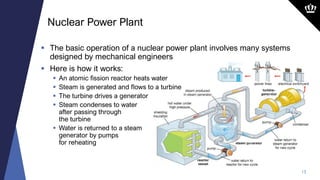

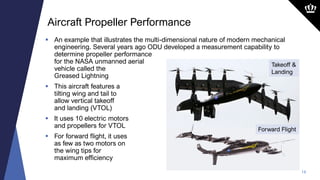

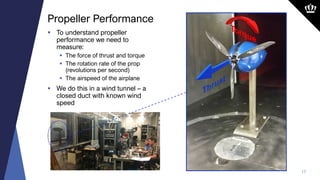

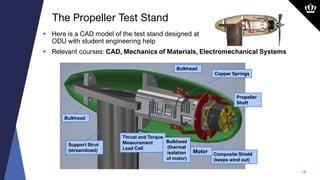

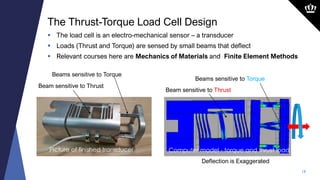

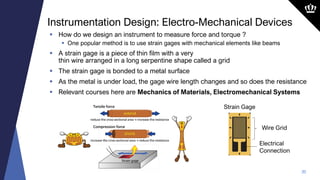

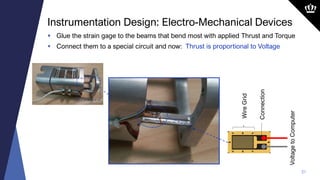

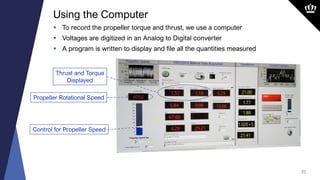

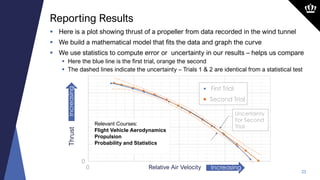

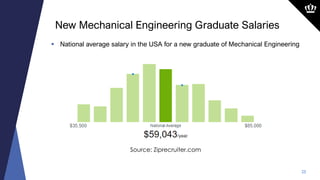

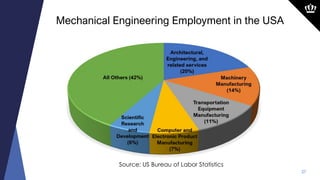

This document provides an introduction to mechanical engineering. It discusses classical definitions of mechanical engineering involving heat, power, and machines. It also discusses how mechanical engineering has evolved to include more modern topics like mechatronics, statistics, and multi-disciplinary fields. Typical jobs for mechanical engineers are also outlined, such as product design, manufacturing, energy production, and systems management. Examples are provided on how mechanical engineers work on wind turbines, nuclear power plants, and measuring aircraft propeller performance to illustrate the breadth of the field.