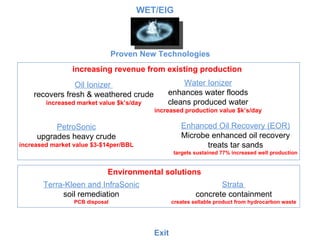

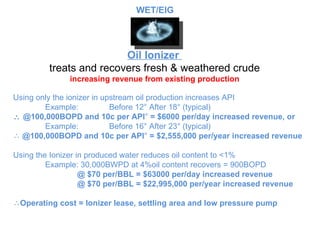

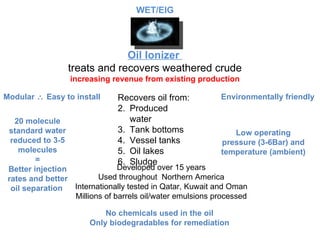

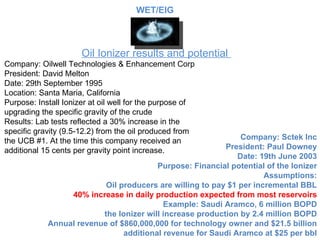

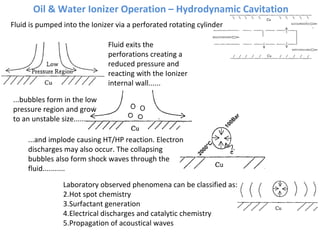

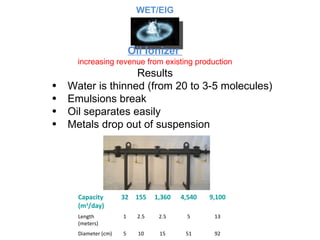

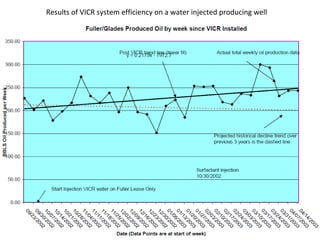

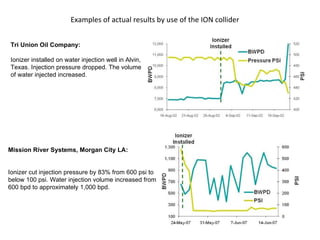

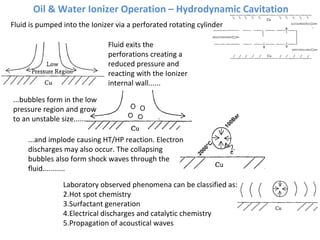

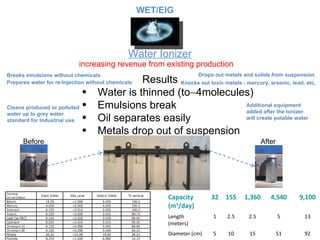

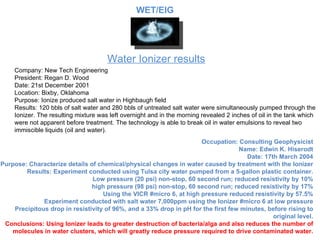

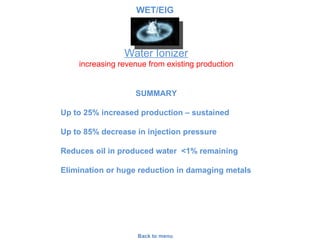

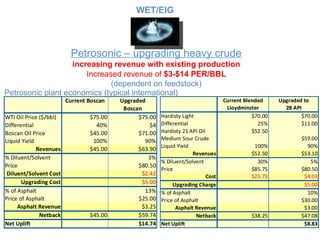

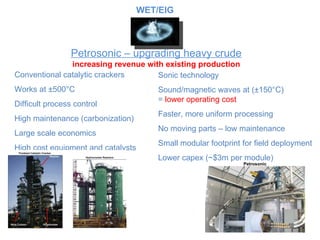

The document introduces several technologies for increasing revenue from existing oil and gas production, including an Oil Ionizer and Water Ionizer. The Oil Ionizer recovers oil from produced water and upgrades crude oil quality, increasing revenue by thousands per day. The Water Ionizer enhances water floods by cleaning produced water, reducing injection pressures and increasing production values and revenue by thousands per day. Field tests and examples from companies show ionization increasing well production by 25-77% and reducing costs by treating and reusing water.