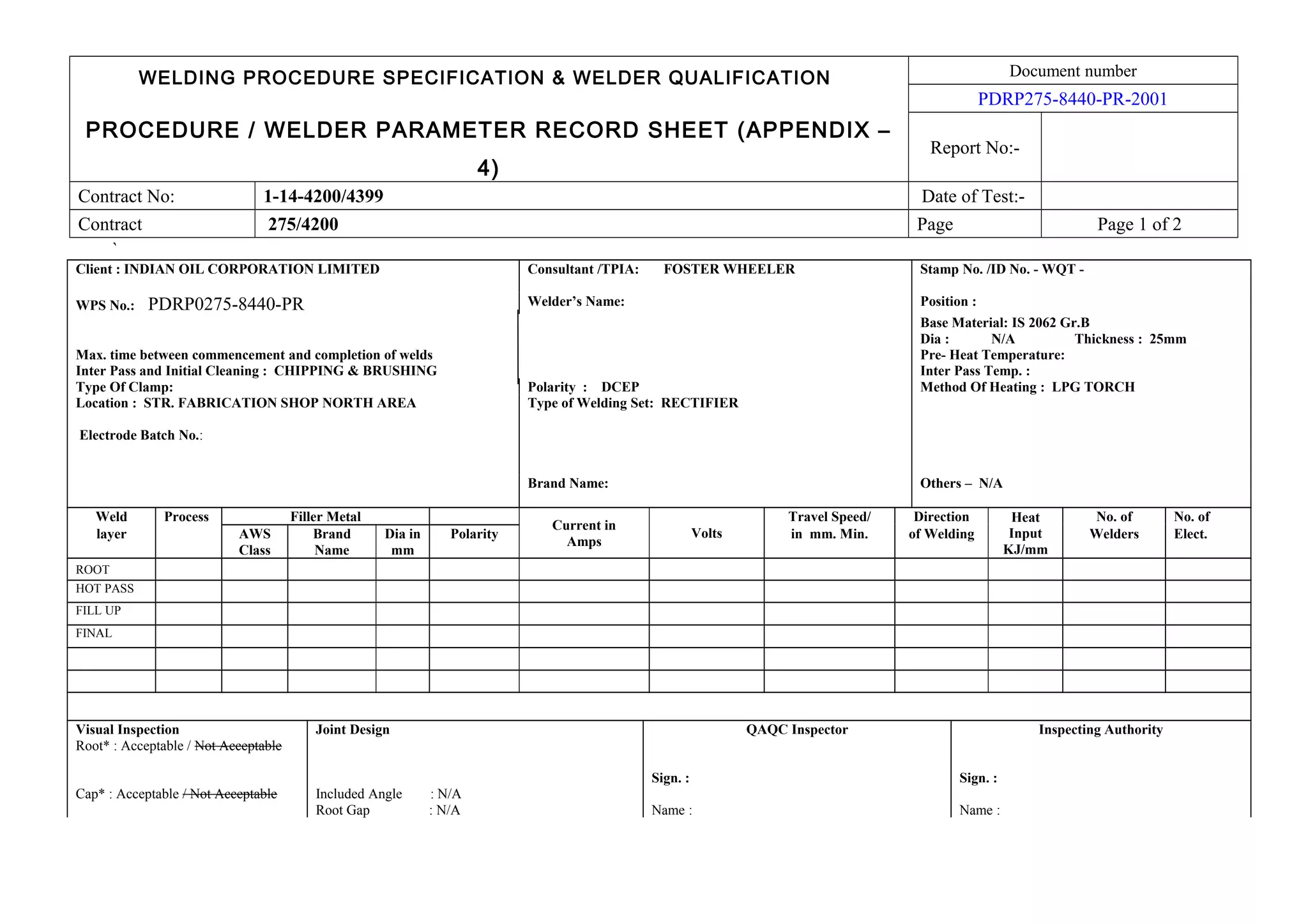

This document provides details of a welding procedure specification and welder qualification test, including the contract and document numbers, client, materials being welded, welding parameters for the root, hot, fill and final passes, and a visual inspection report. It lists the welding process, filler metal type and size, current, voltage, travel speed, heat input, and number of welders and electrodes used. The joint design, root and cap inspections, and approvals of the quality assurance coordinator and inspecting authority are also included.