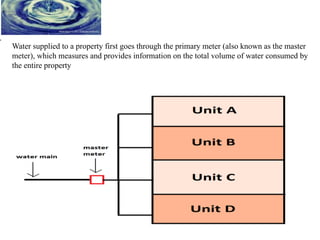

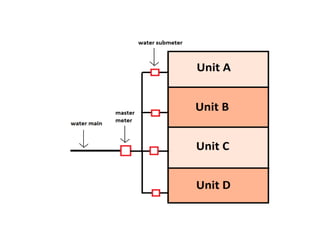

Water sub metering allows property owners and managers to measure water consumption within individual units or fixtures on a property. A sub-meter is installed downstream of the primary meter to measure water usage for specific areas. Sub-metering provides data on individual unit consumption, enabling landlords to charge tenants based on actual usage and identify water conservation opportunities. It can help reduce overall water usage when tenants are accountable for their own consumption.