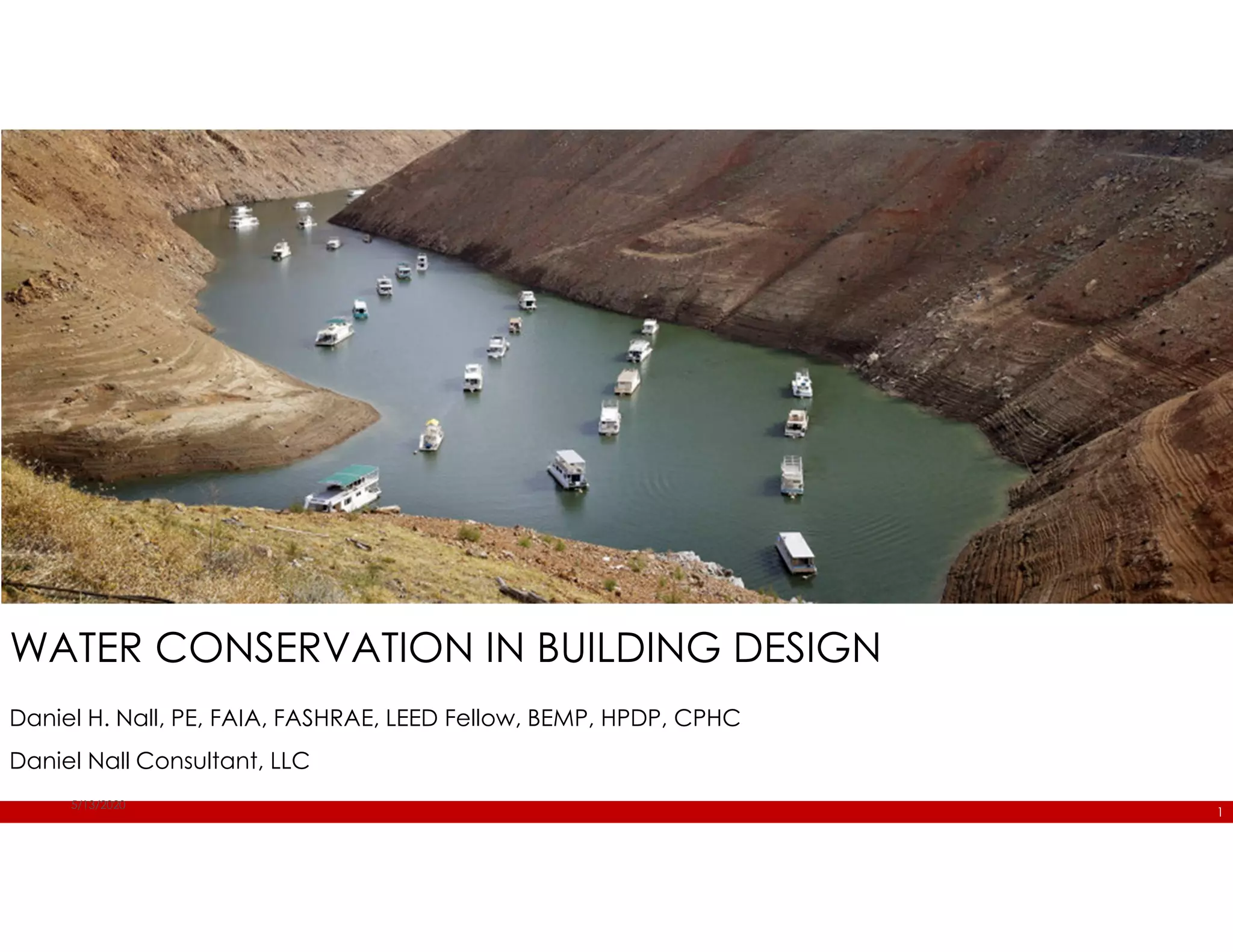

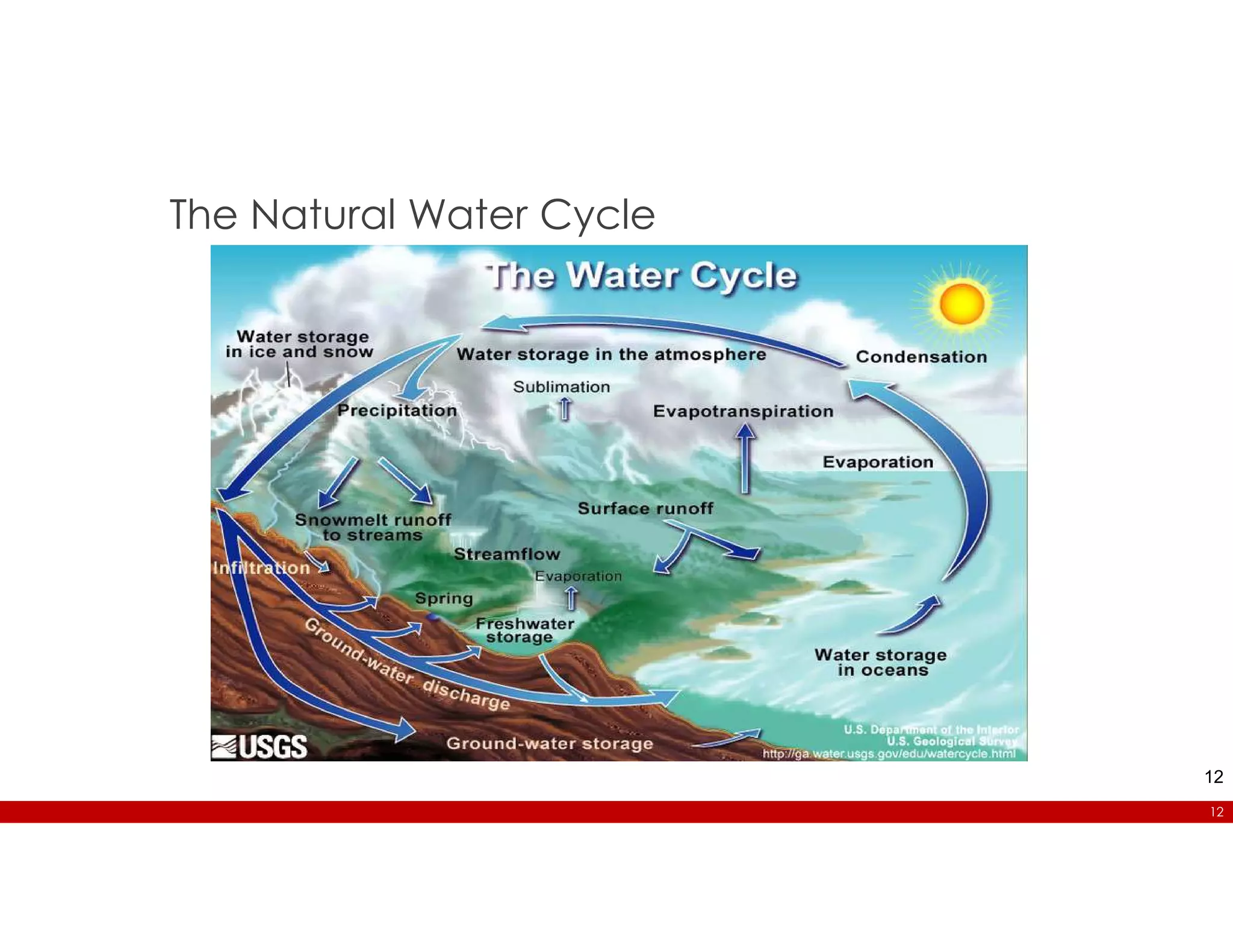

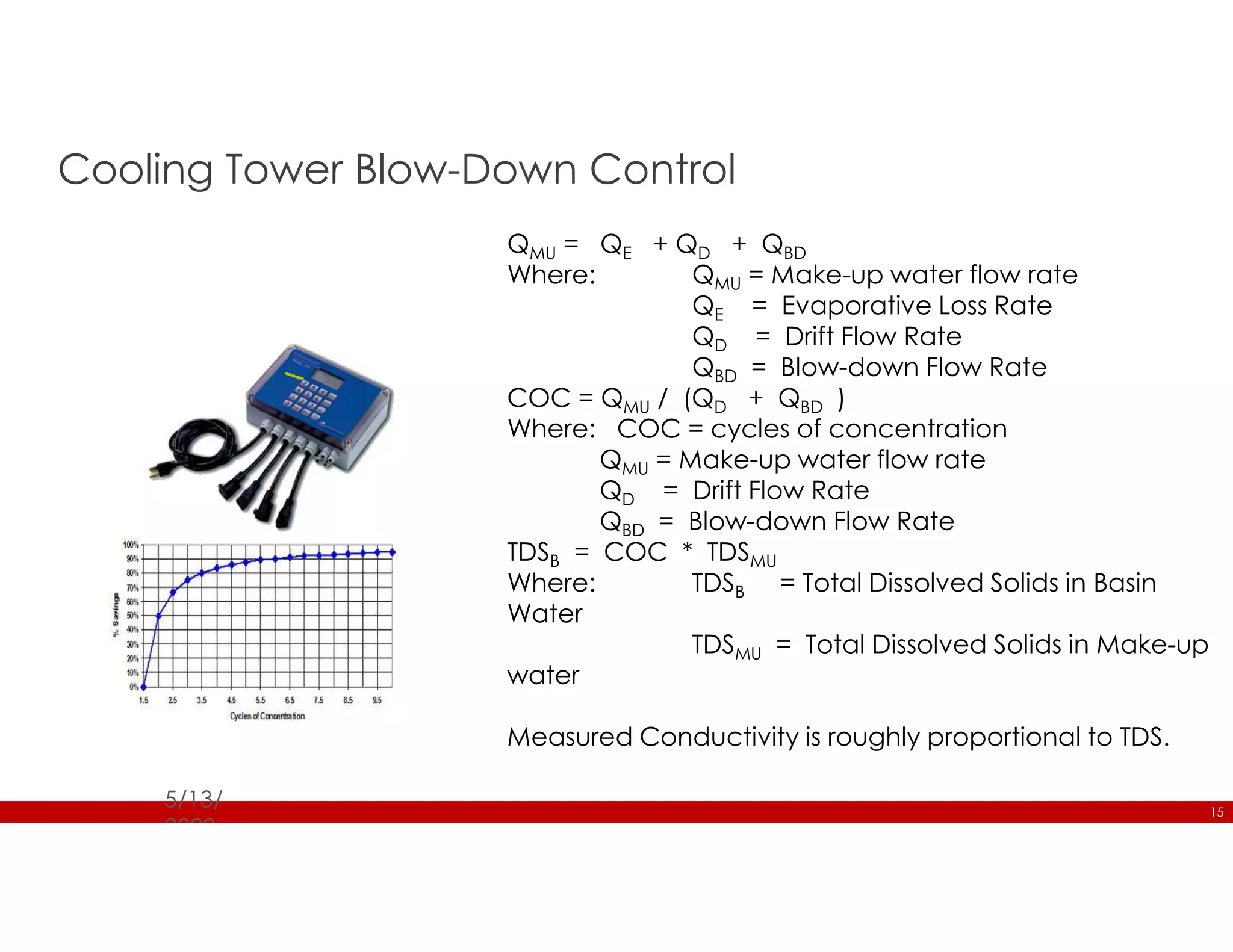

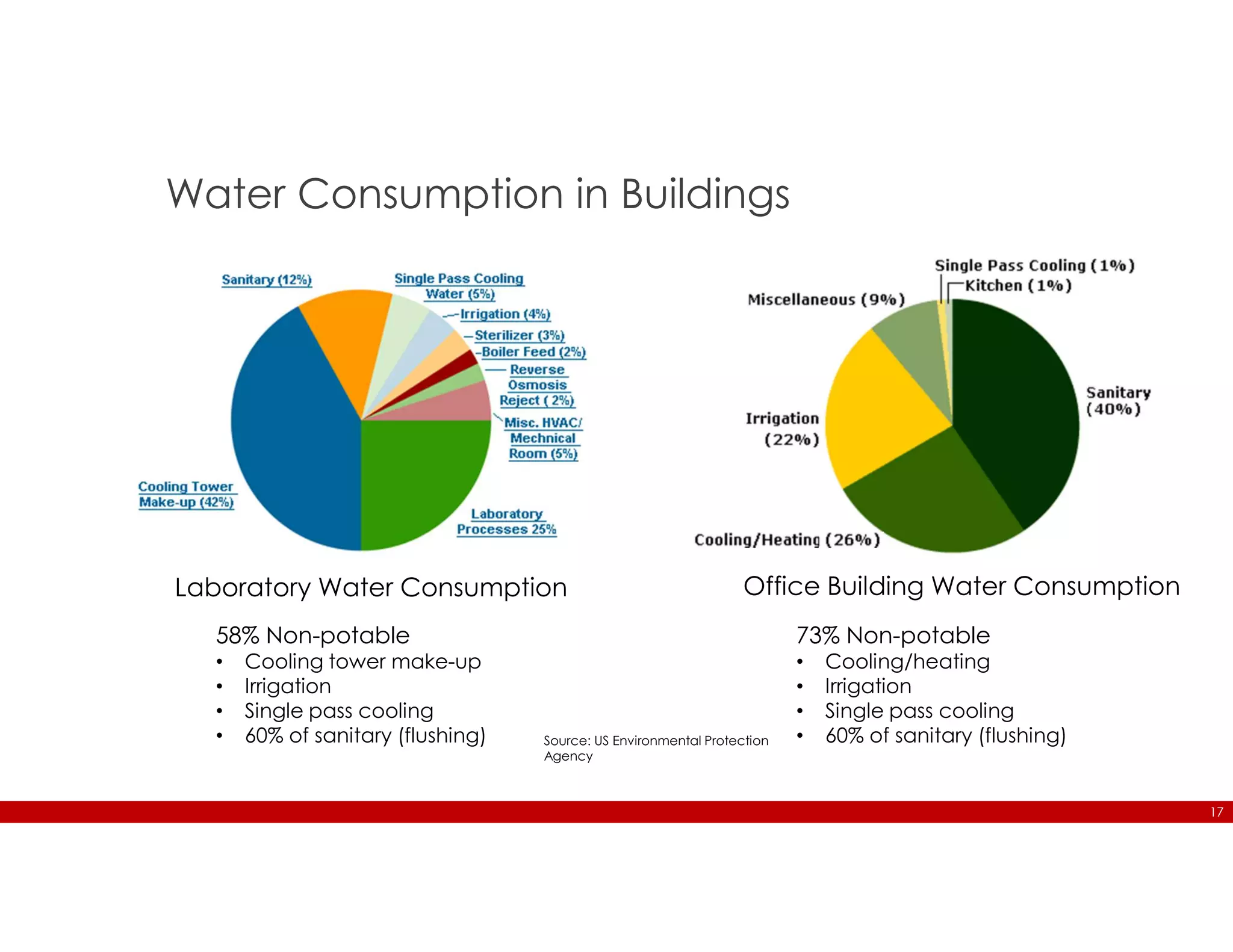

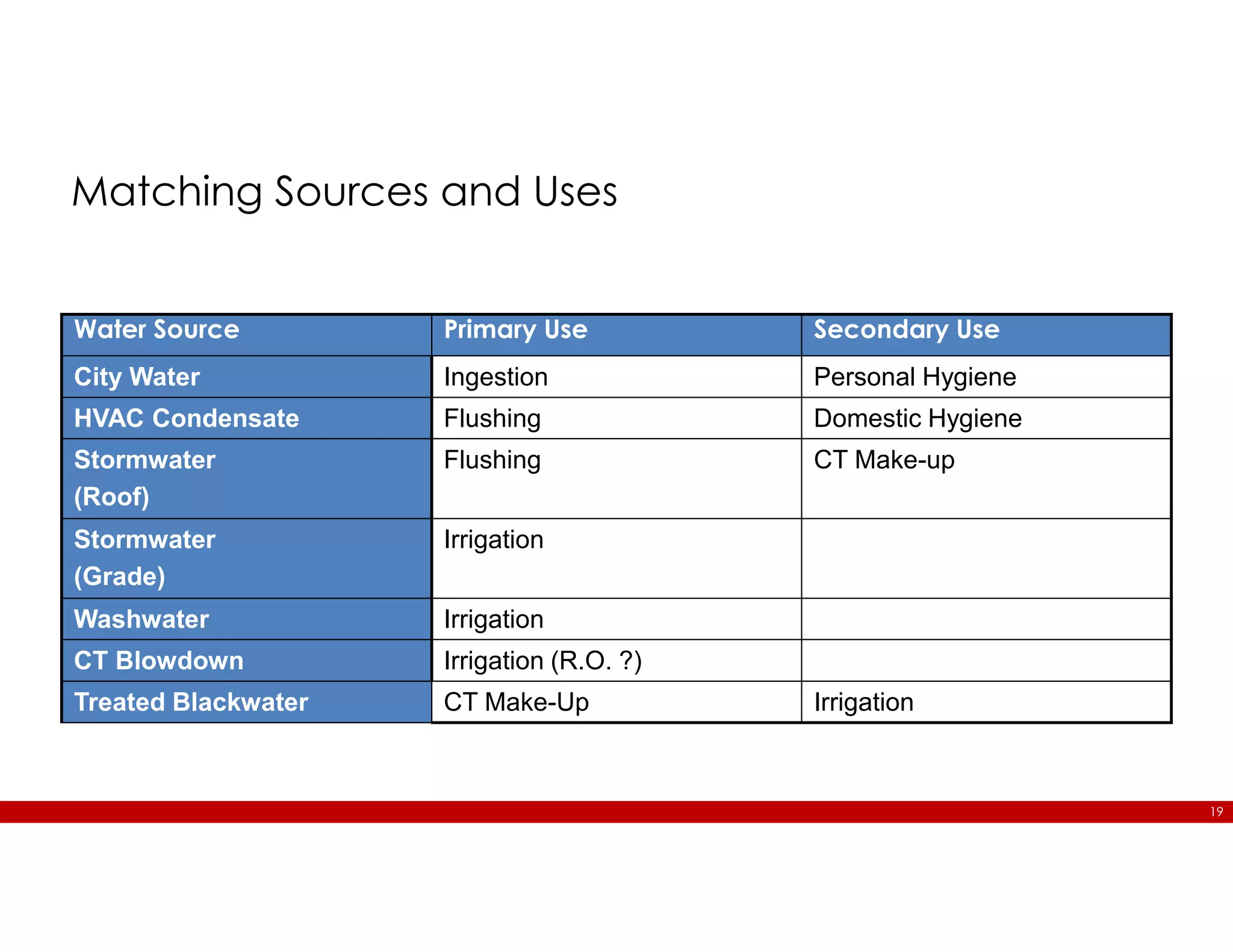

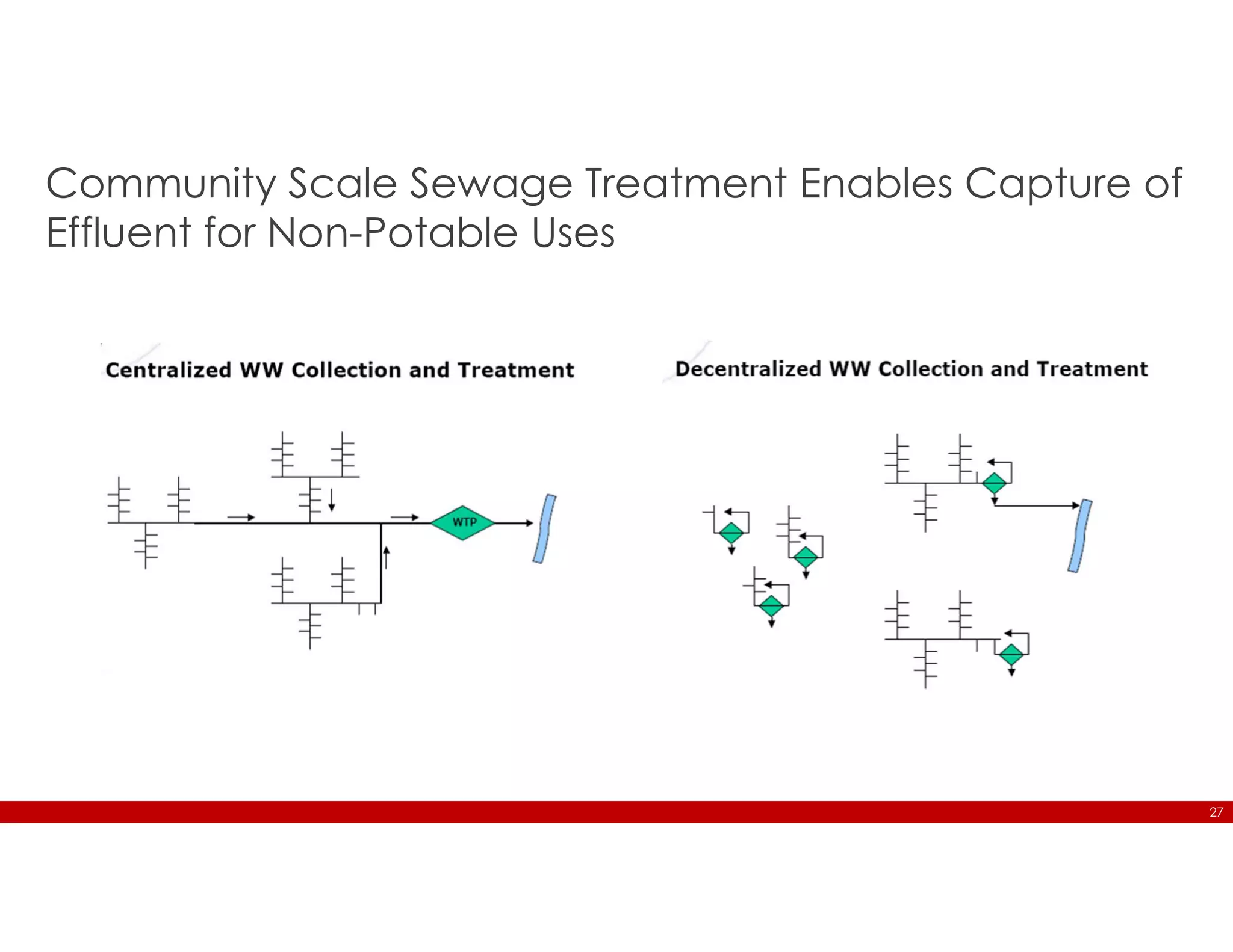

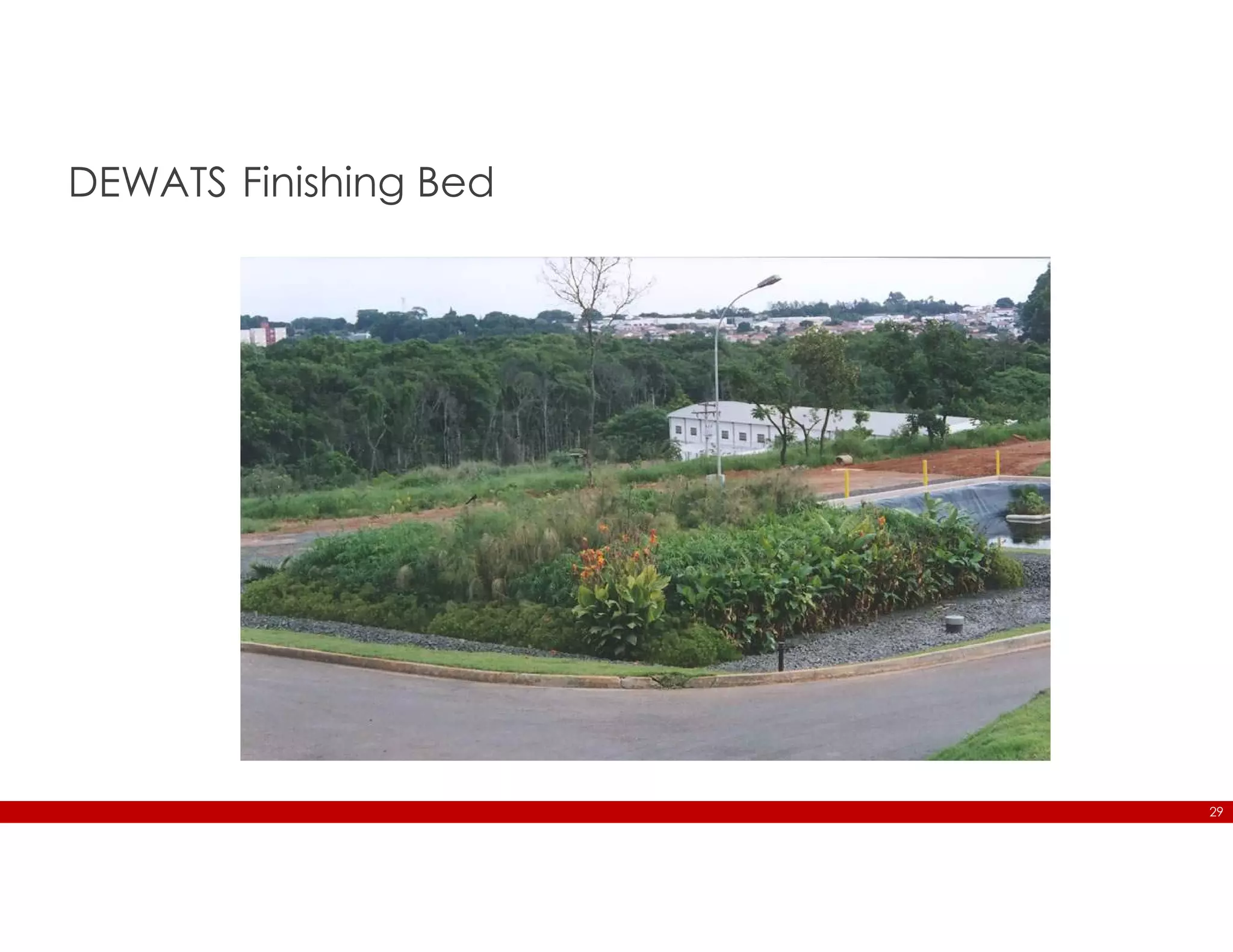

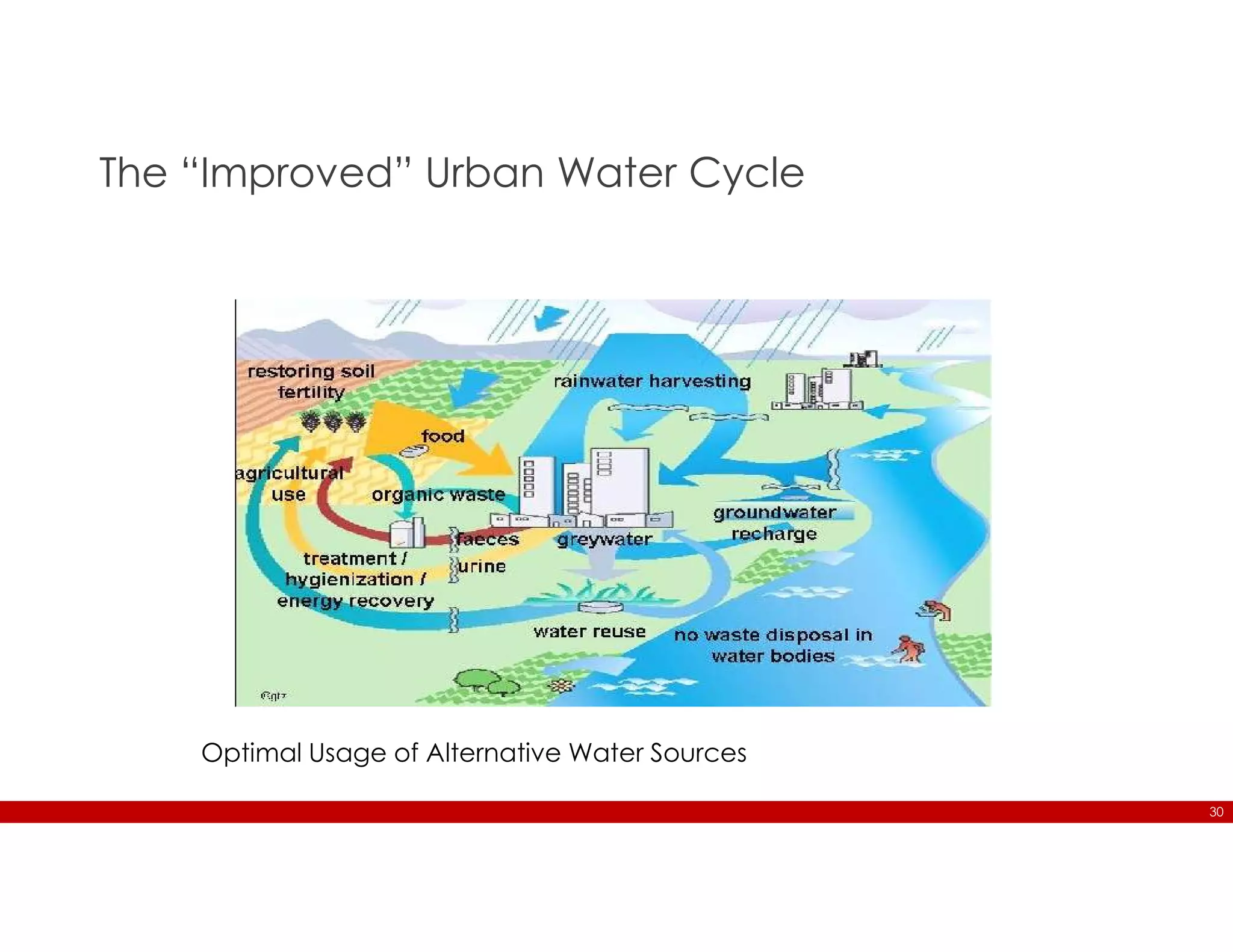

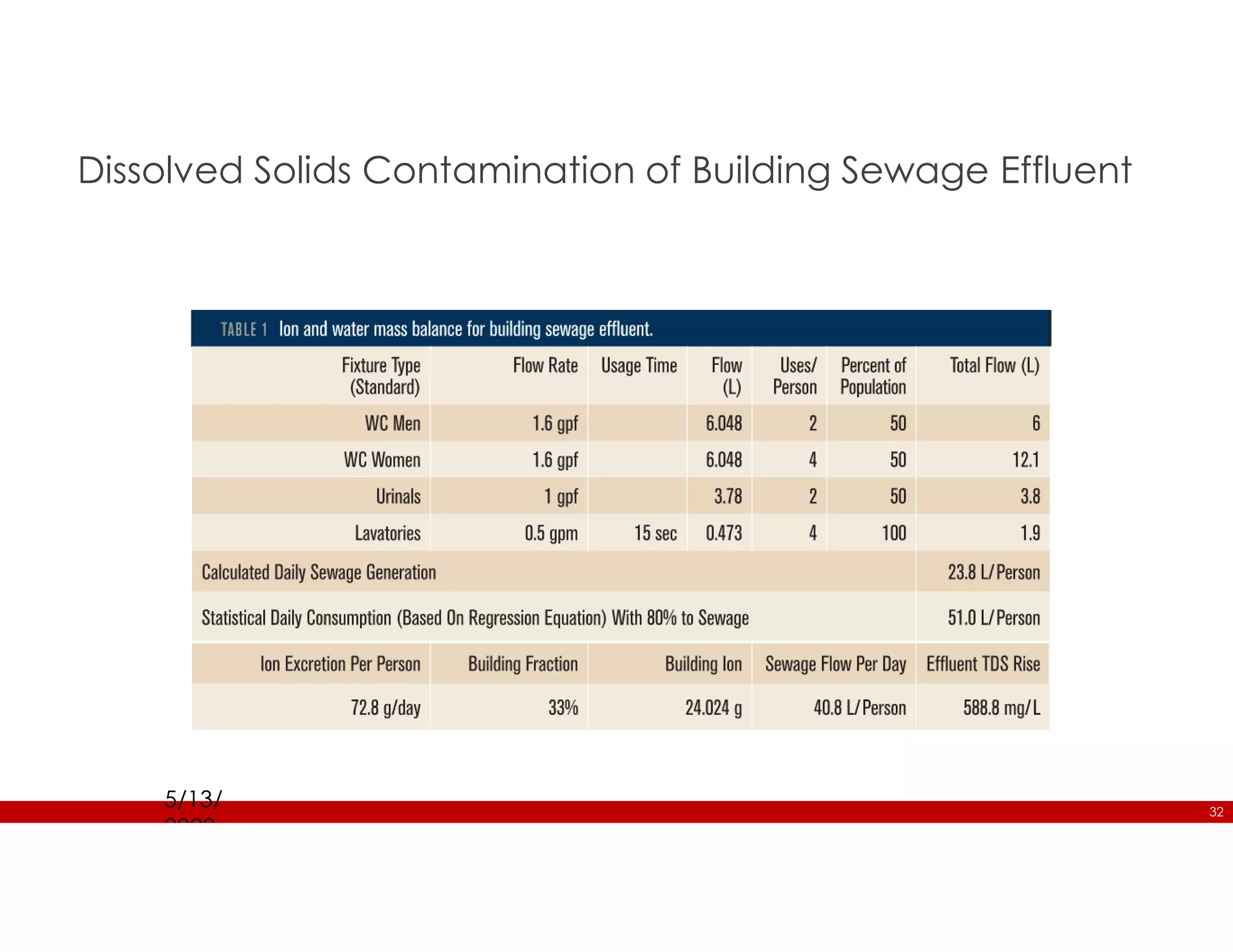

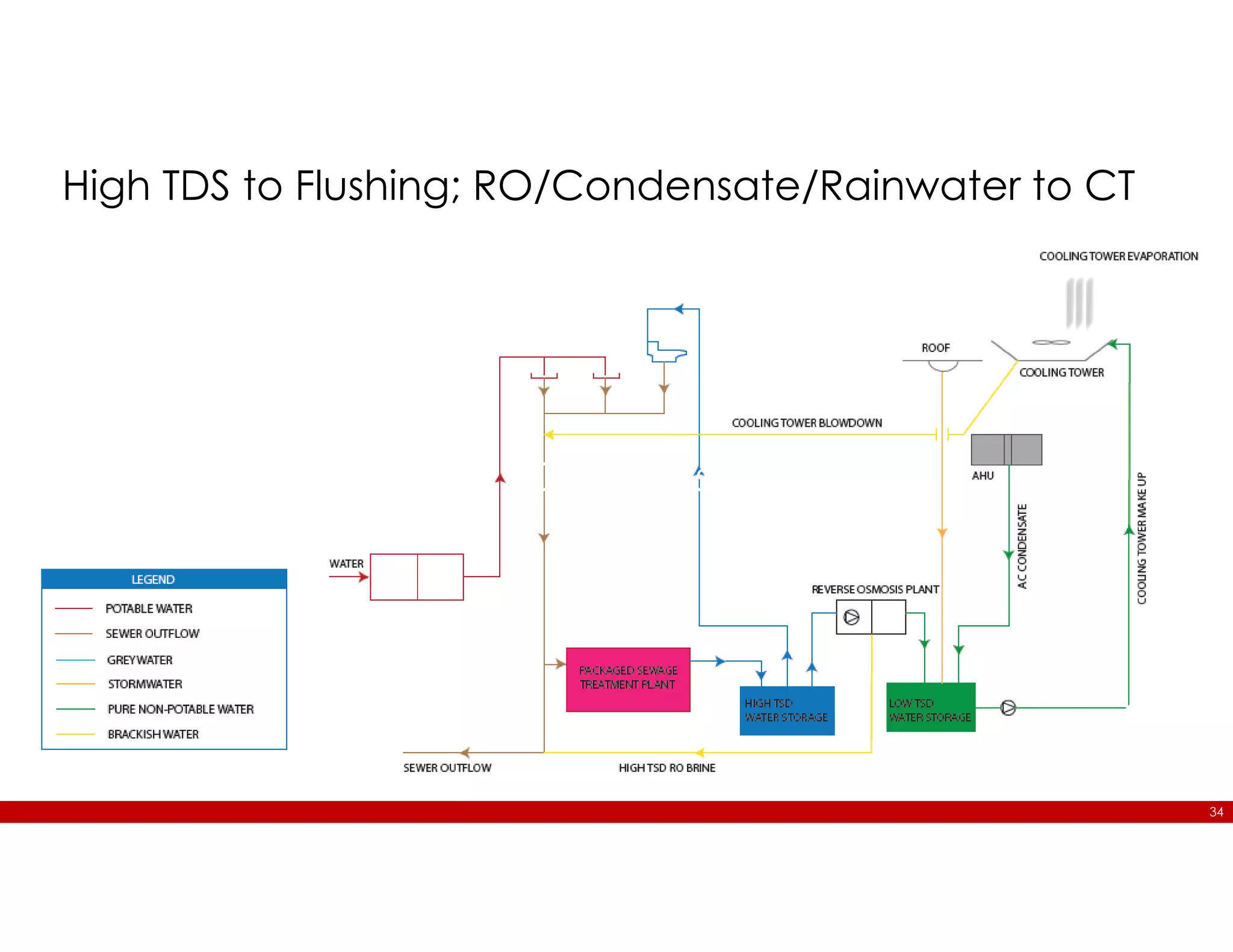

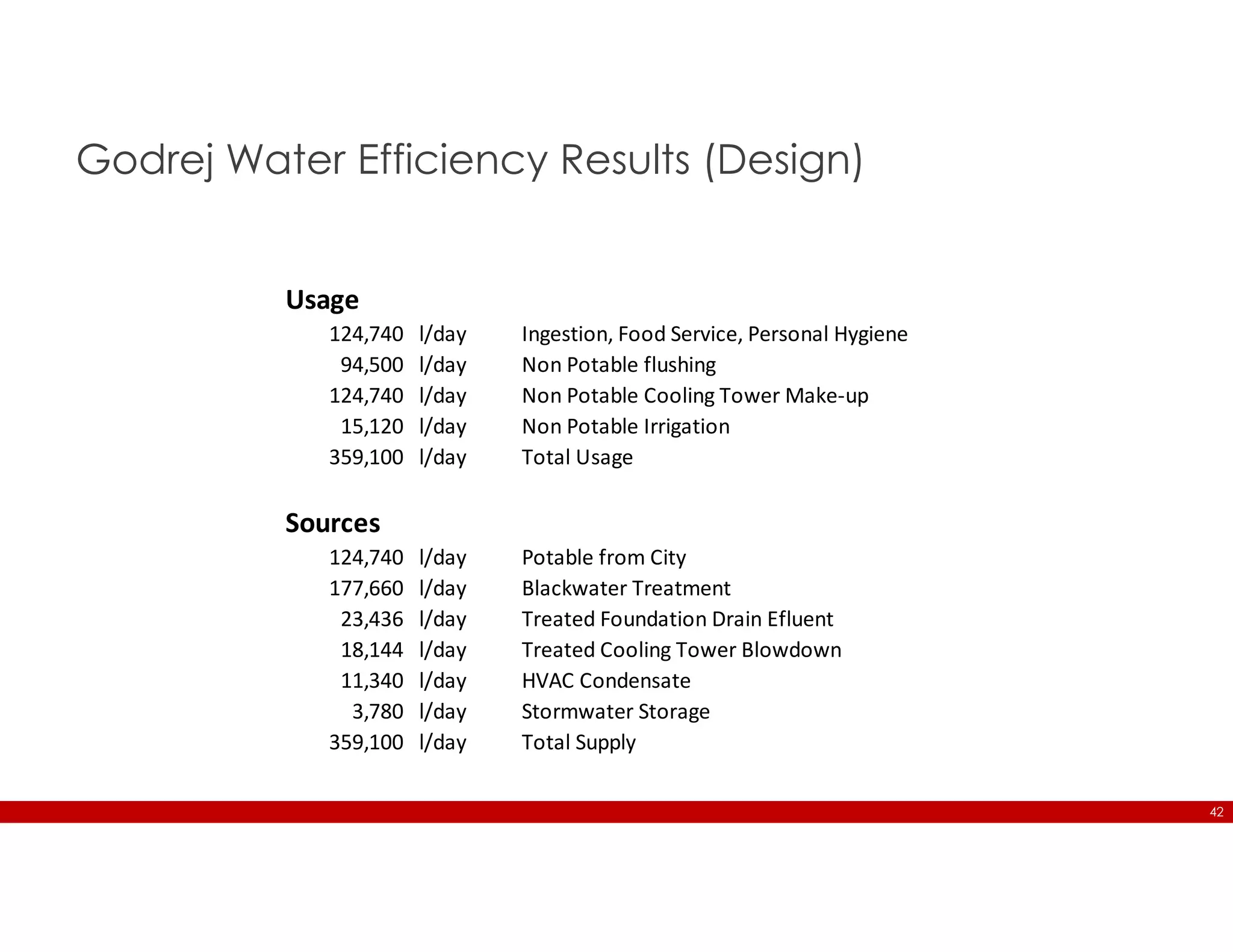

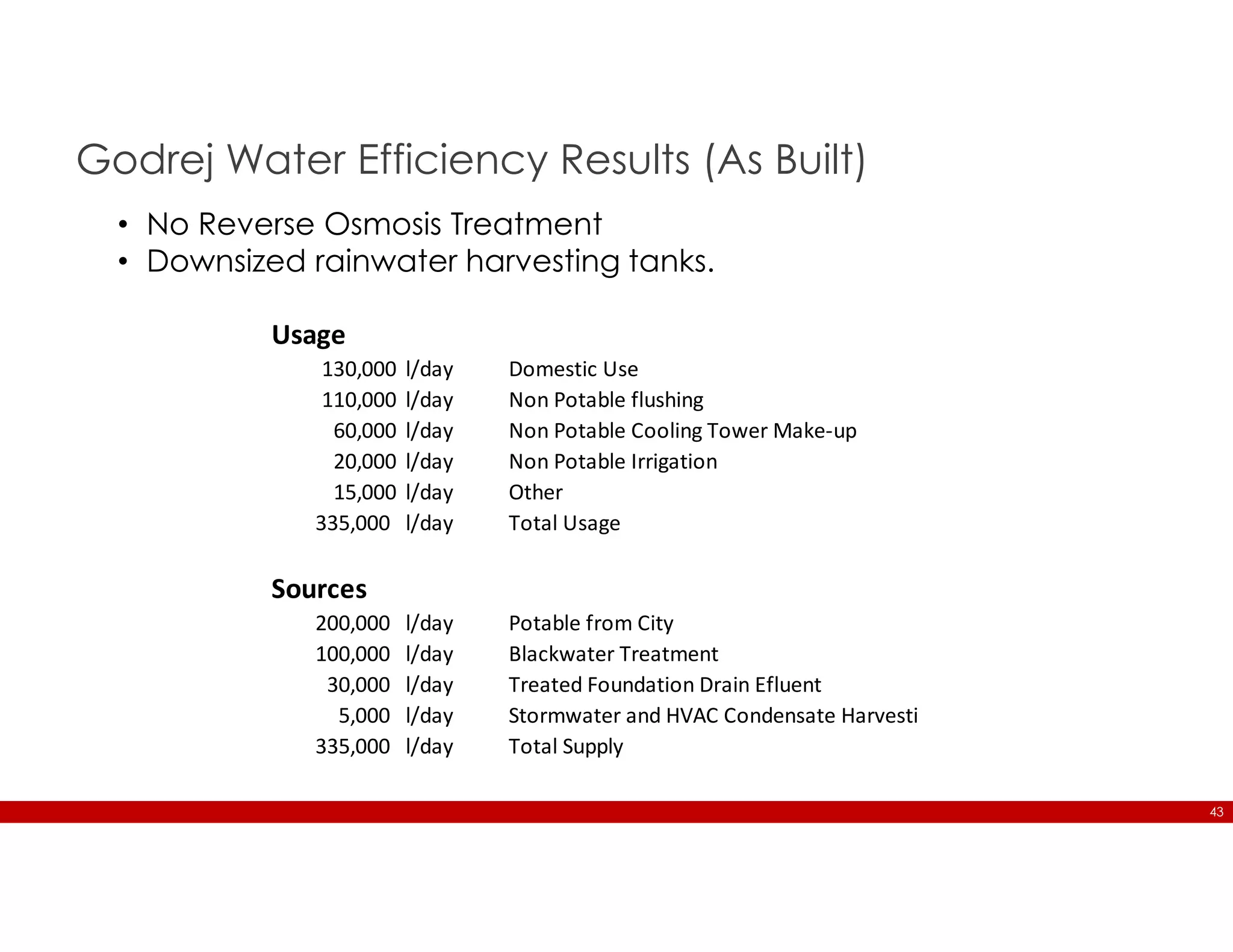

The document discusses water conservation in building design. It begins with an introduction to the upcoming global water crisis and opportunities for water conservation in buildings. It then discusses non-potable water resources that can be captured in buildings, such as HVAC condensate, stormwater, and graywater. Treatment options are presented for non-potable water, including dealing with total dissolved solids. Finally, a case study is described that achieved a 2/3 reduction in potable water usage through conservation measures and non-potable water harvesting at the Godrej Headquarters in India.