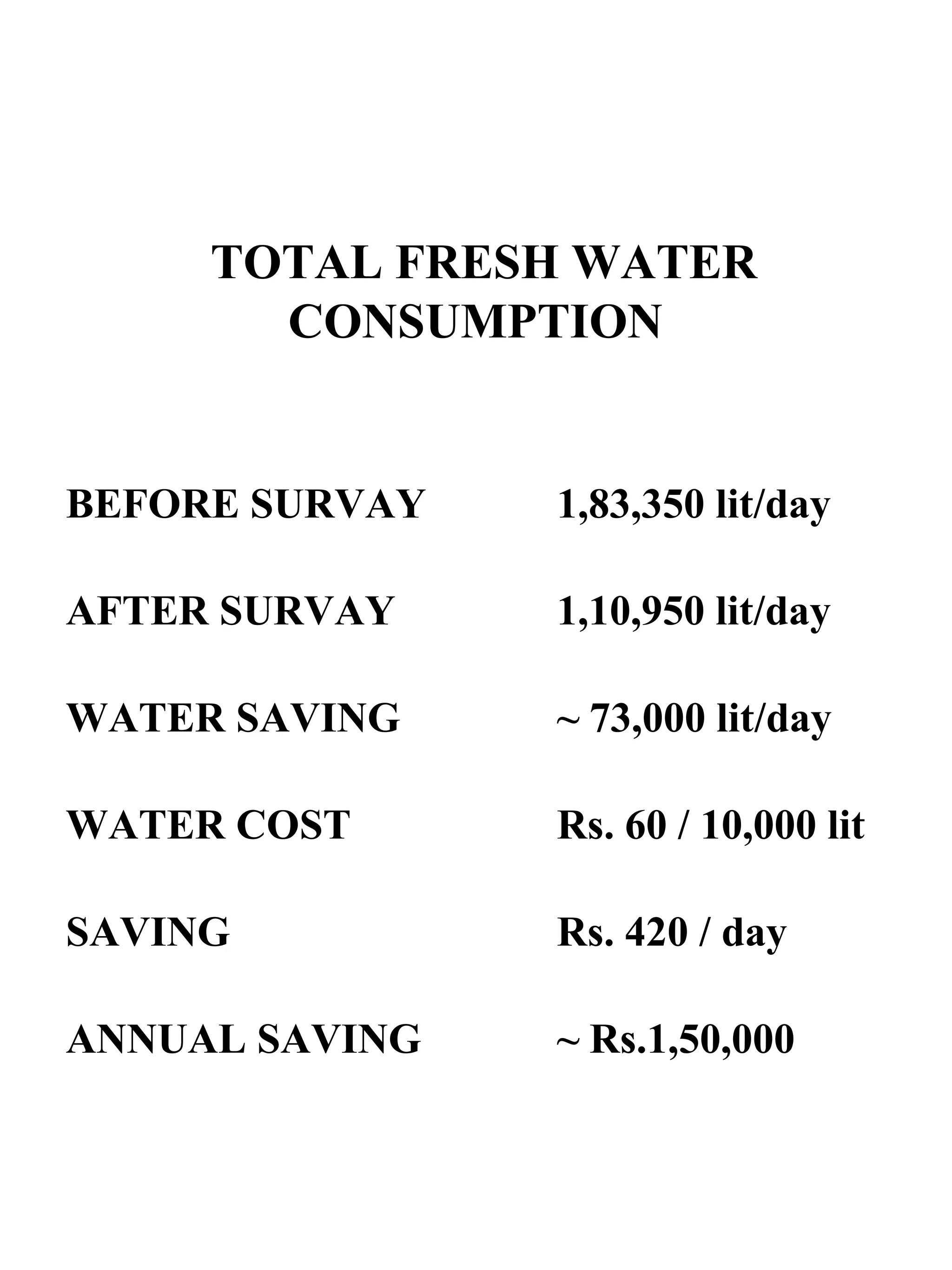

This document discusses various methods for water conservation in textile processing, which can reduce effluent volume and treatment costs. Key methods mentioned include improving housekeeping to fix leaks, installing water meters, reusing cooling and washing water through countercurrent flow systems, and optimizing chemical usage. Case studies show that these measures have successfully reduced fresh water consumption by up to 40% and lowered biochemical oxygen demand in effluent.