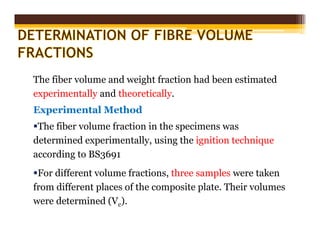

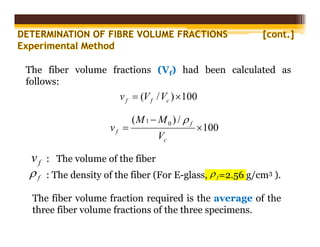

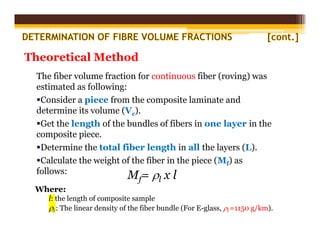

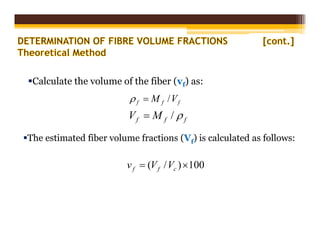

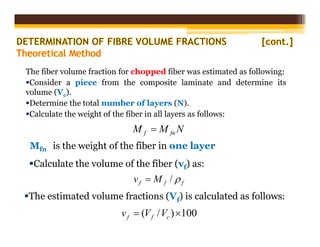

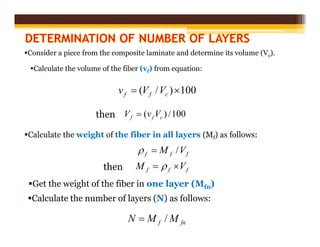

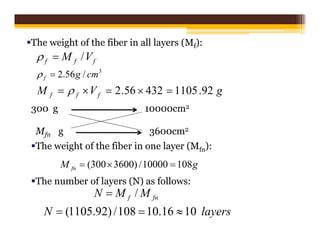

The document describes methods to experimentally determine fiber volume fraction and void content in fiber reinforced composites. Fiber volume fraction is determined by burning off the resin matrix and measuring fiber mass and density. Void content is calculated from theoretical density based on fiber/resin properties and densities, and experimental density measured via liquid displacement. An example calculates fiber volume fraction of 30% and number of layers as 10 for a glass/epoxy composite. It also calculates theoretical density as 1.36 g/cm3, experimental density as 1.29 g/cm3, and void content as 5.15% for a Kelvar/polyester laminate sample.

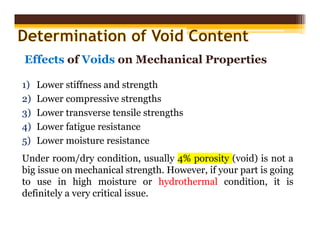

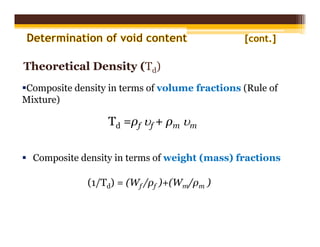

![The knowledge of void content is desirable for estimation of

quality of composites.

The void content of the composites was calculated

according to the ASTM D2734-94 standard:

V=[(Td –Md )/ Td]x100

Where:

V is the void content (vol.%),

Td the theoretical density (g/cm3)

Md is the measured density (g/cm3).](https://image.slidesharecdn.com/lecture06-230124110258-ce9ac57d/85/volume-fraction-11-320.jpg)

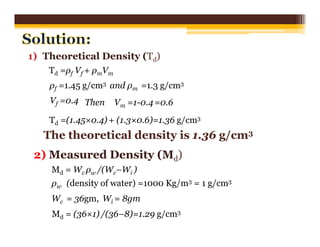

![The measured density (Md) is 1.29 g/cm3

2) The void content of the composites was

calculated as:

V=[(Td–Md)/Td]x100=[(1.36-1.29)/1.36]

x100=5.15%

The void content is 5%

V=[(Td –Md )/ Td]x100](https://image.slidesharecdn.com/lecture06-230124110258-ce9ac57d/85/volume-fraction-16-320.jpg)