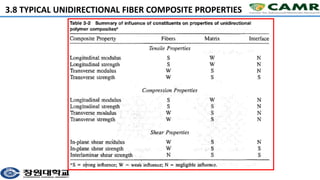

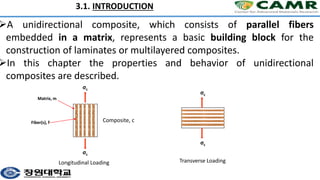

1) The document discusses the behavior and properties of unidirectional composites, which consist of parallel fibers embedded in a matrix. It describes methods for predicting the longitudinal and transverse stiffness and strength of these composites.

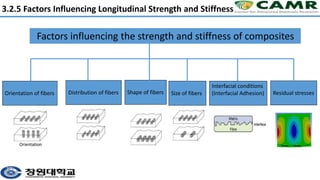

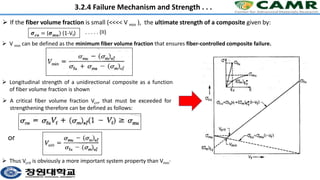

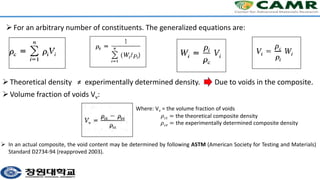

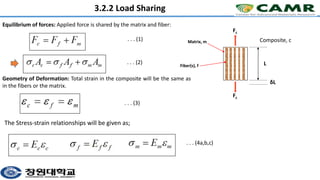

2) The rule of mixtures is presented as a way to calculate the longitudinal stiffness and strength of a composite based on the properties of its constituents and their volume fractions. Factors that influence the longitudinal properties are also discussed.

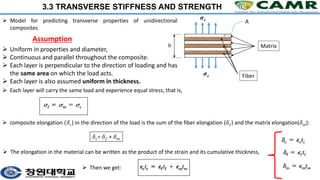

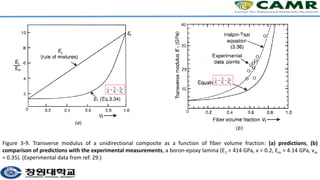

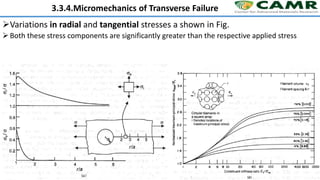

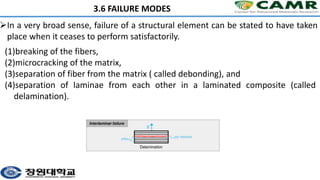

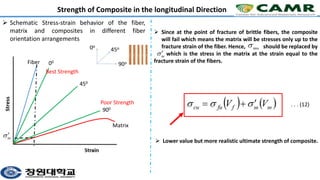

3) Transverse properties are generally much lower than longitudinal properties due to the orientation of the fibers. Methods for predicting transverse stiffness using elasticity principles are described. Failure modes in composites include fiber breaking and matrix microcracking.

![Course Title: Smart Materials Engineering

[SMB2003-00]

CHAPTER THREE: Behavior of Unidirectional Composites

March 2023

Reference: Analysis and Performance of Fiber Composites, Agarwal, B.D.](https://image.slidesharecdn.com/ch3-230331001938-e8ed378e/85/CH-3-pptx-1-320.jpg)

![3.2.3 Behavior beyond Initial Deformation

The rule of mixtures accurately predicts the stress-strain behavior of a unidirectional

composite subjected to longitudinal loads, provided that Eq. (1) is used for the stress and Eq.

(2) for the slope of the stress-strain curve.

However, the simplification of Eq. (2) to Eq. (3) through the replacement of slopes by the

elastic moduli is possible only when both the constituents deform elastically.

This may constitute only a small portion of the composite stress-strain behavior and is

applicable primarily for glass or ceramic-fiber-reinforced thermosetting plastics.

In general, the deformation of a composite may proceed in four stages [l], summarized as

follows:

1. Both the fibers and the matrix deform in a linear elastic fashion.

2. The fibers continue to deform elastically, but the matrix now deforms nonlinearly/plastically.

3. The fibers and the matrix both deform nonlinearly or plastically.

4. The fibers fracture followed by the composite fracture.](https://image.slidesharecdn.com/ch3-230331001938-e8ed378e/85/CH-3-pptx-17-320.jpg)