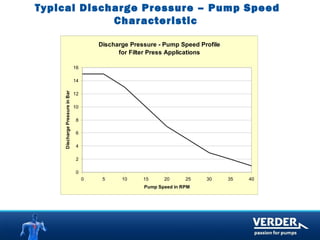

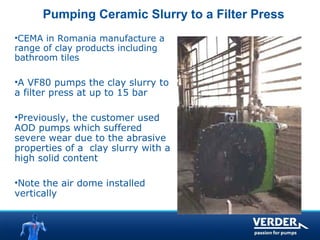

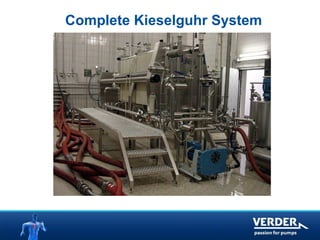

The document discusses the operational sequence of filter presses and the advantages of using hose pumps for various applications, highlighting their leak-free design and gentle pumping action. It mentions challenges faced in specific applications, such as back pressure management and abrasive materials, and cites examples of successful pump implementations in industries like ceramics and brewing. The summary emphasizes the importance of careful gearbox specification and the potential for ongoing sales in filter press applications.