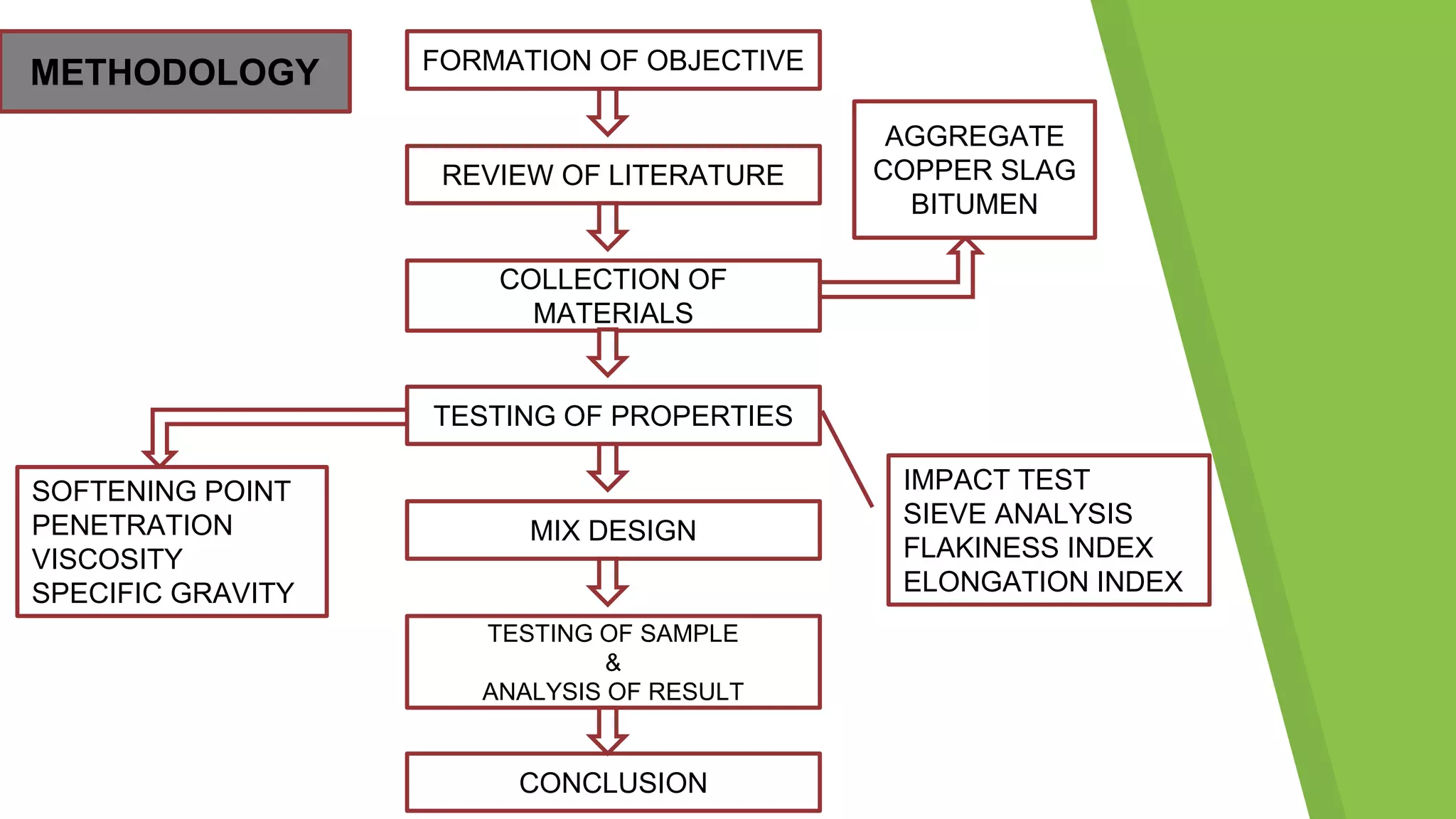

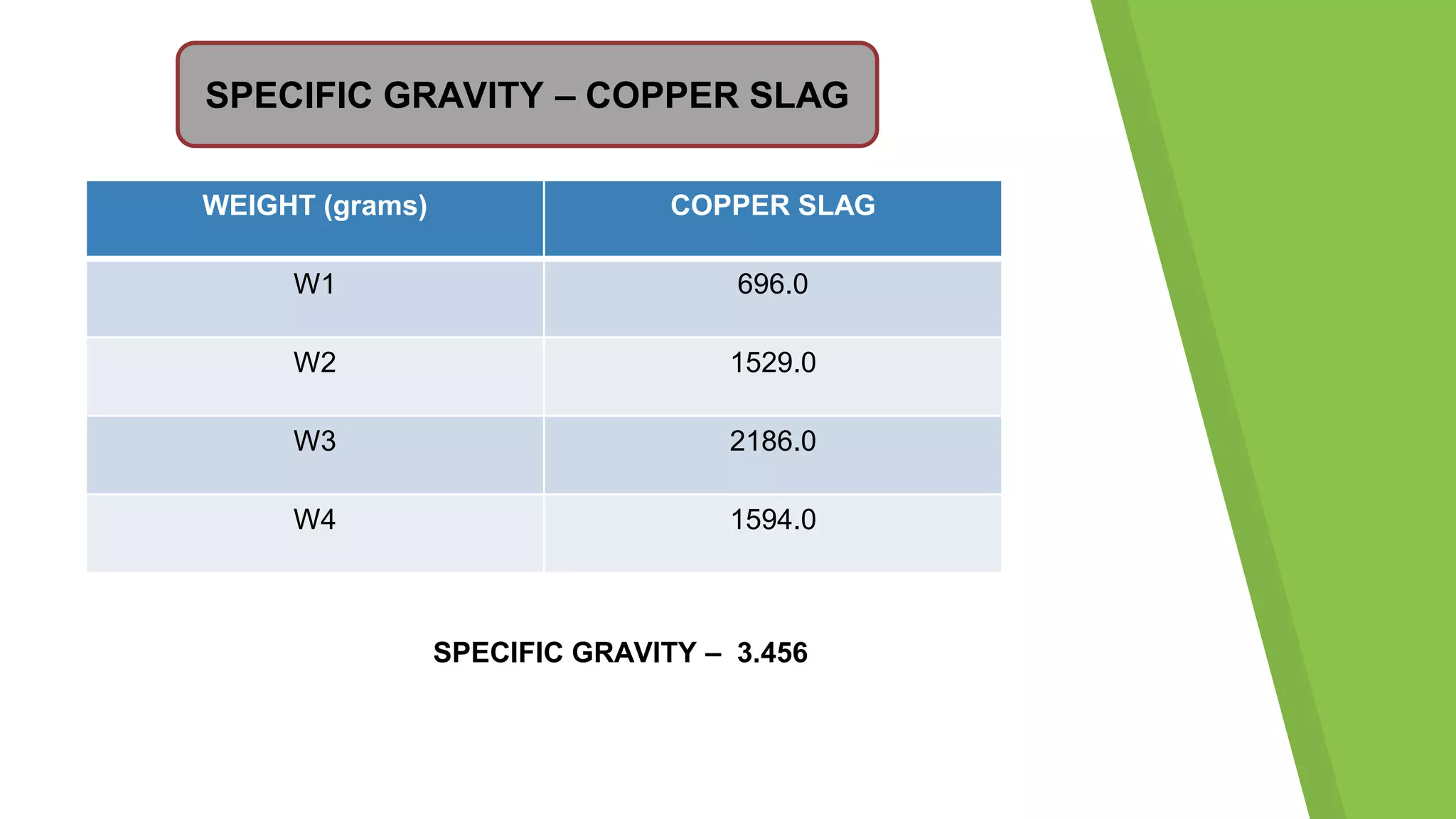

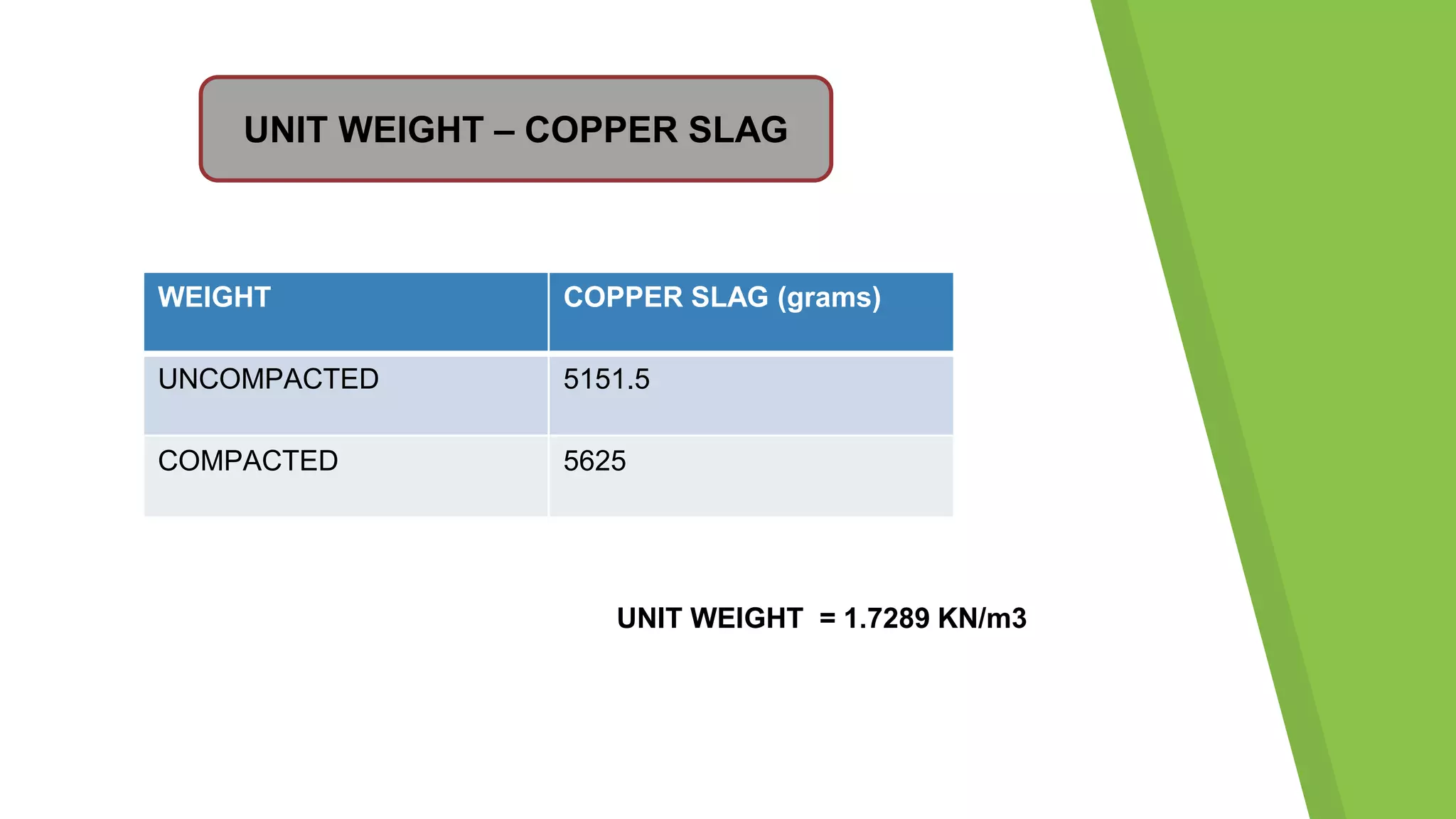

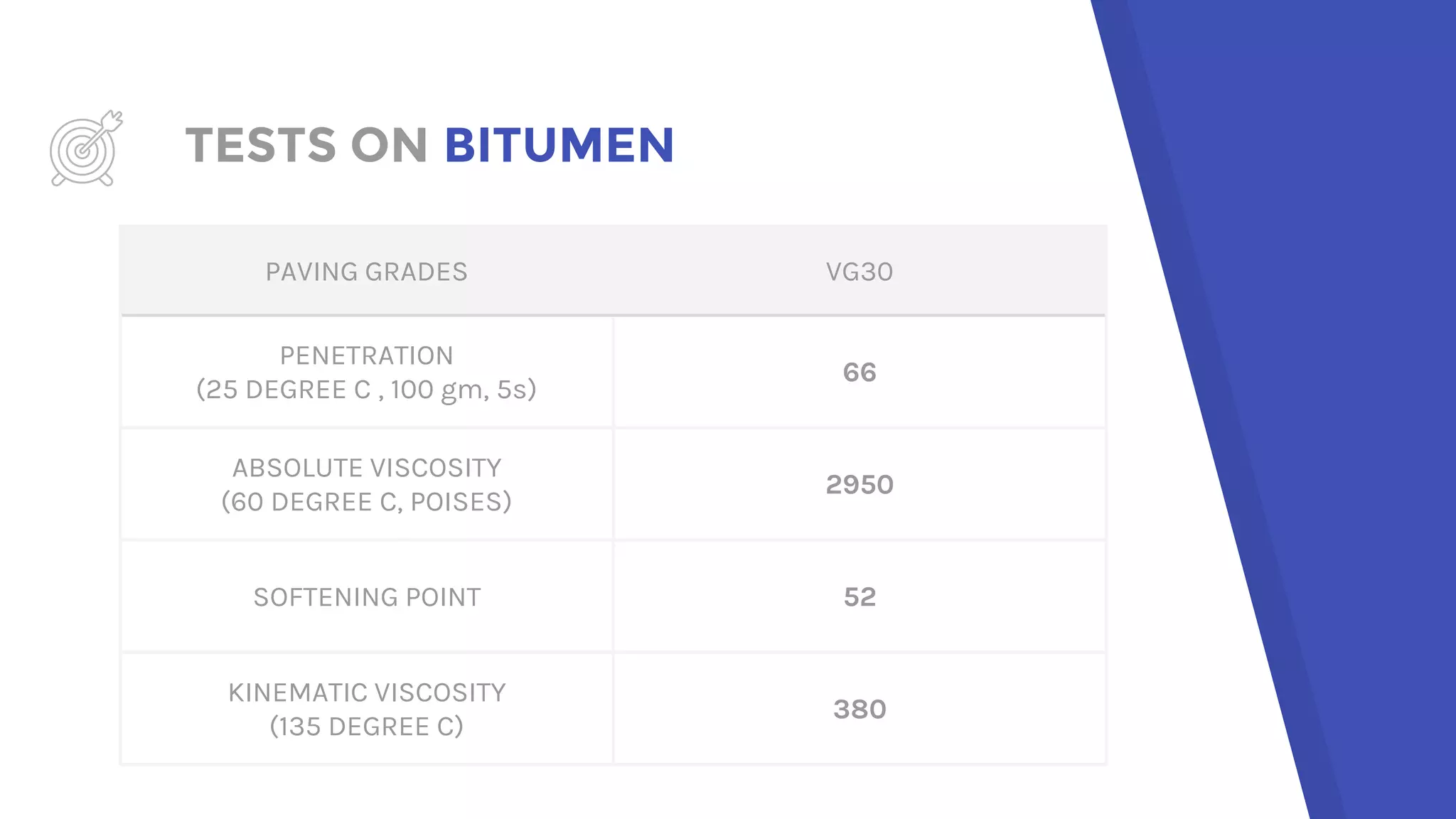

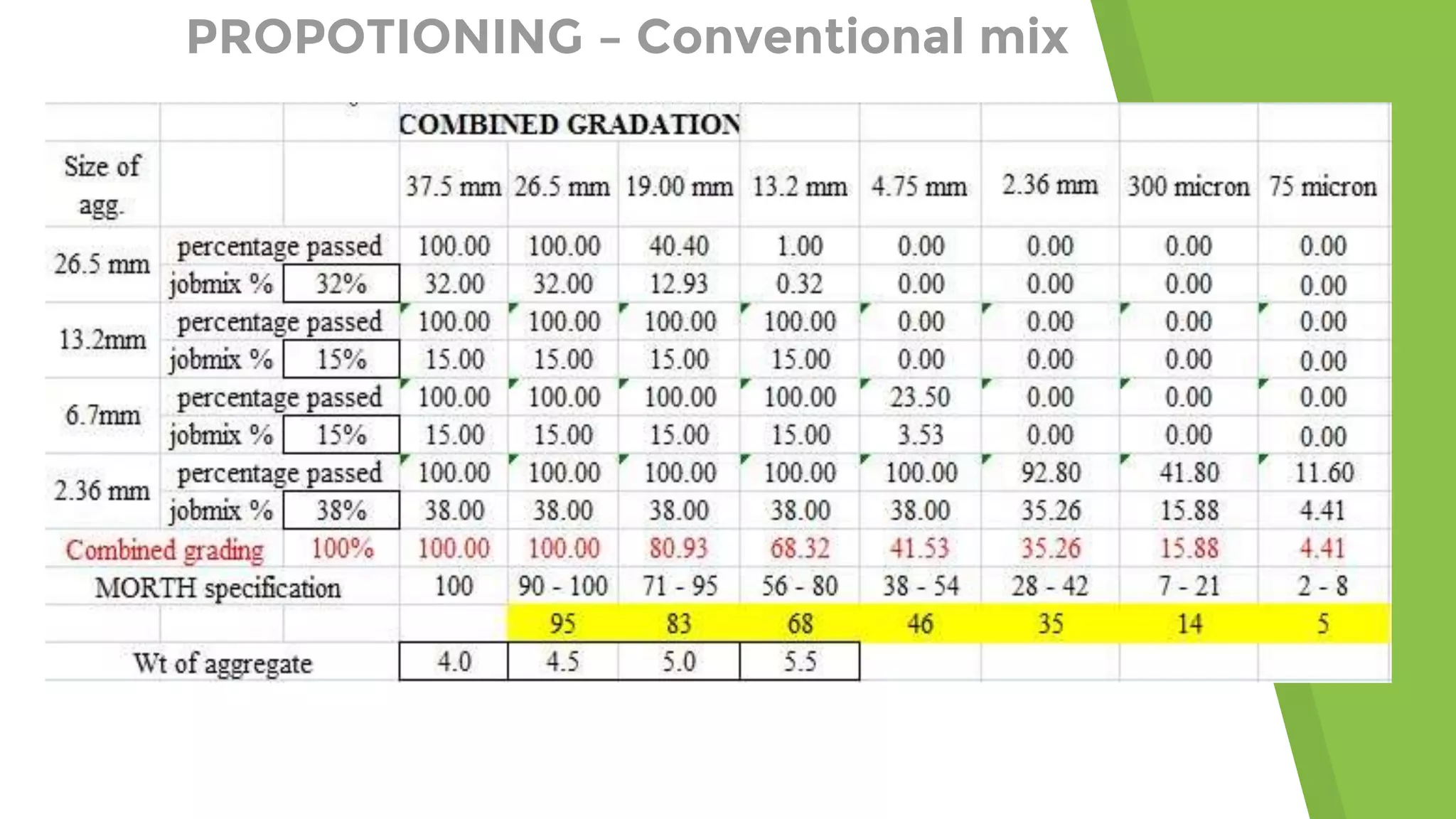

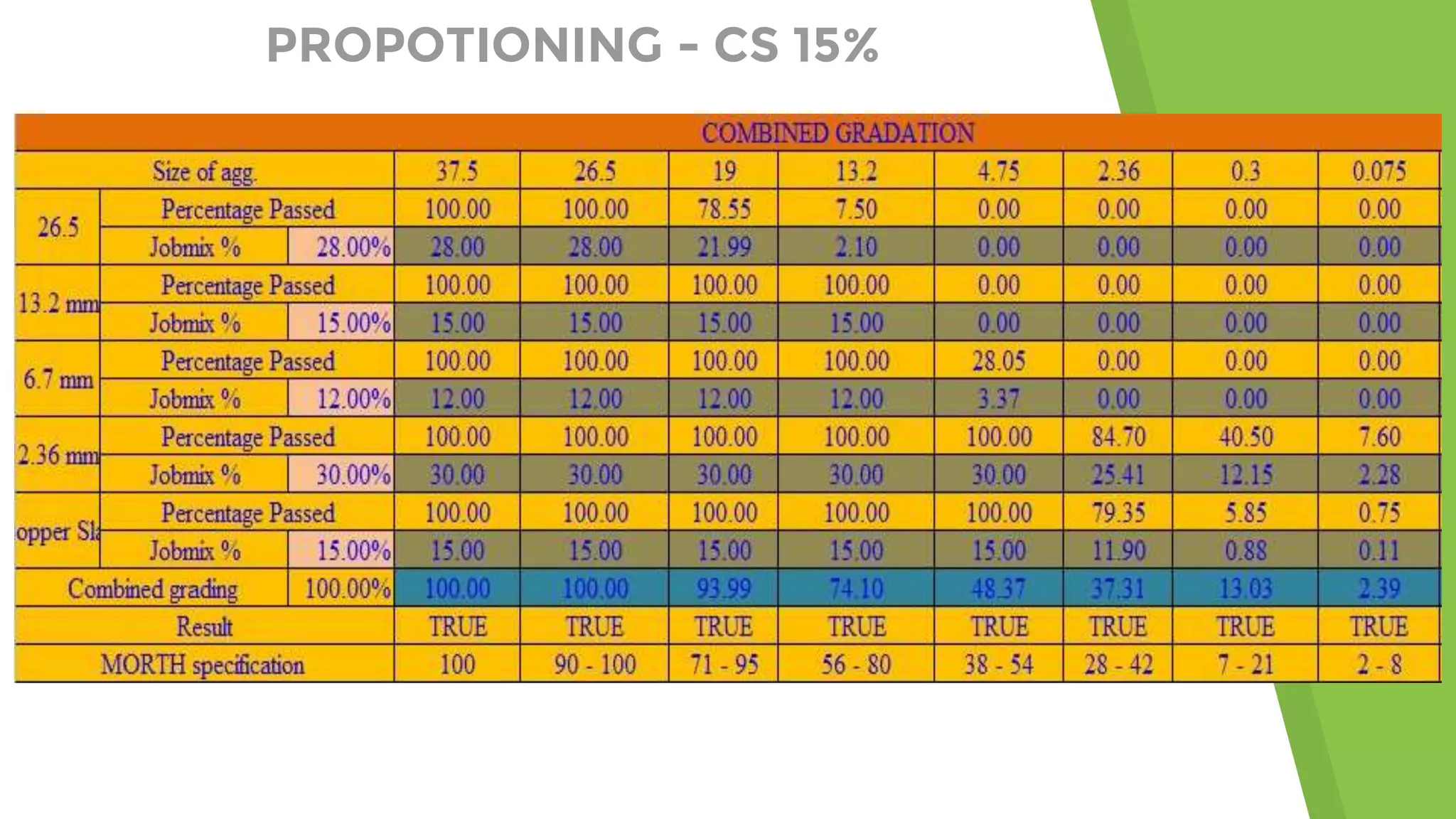

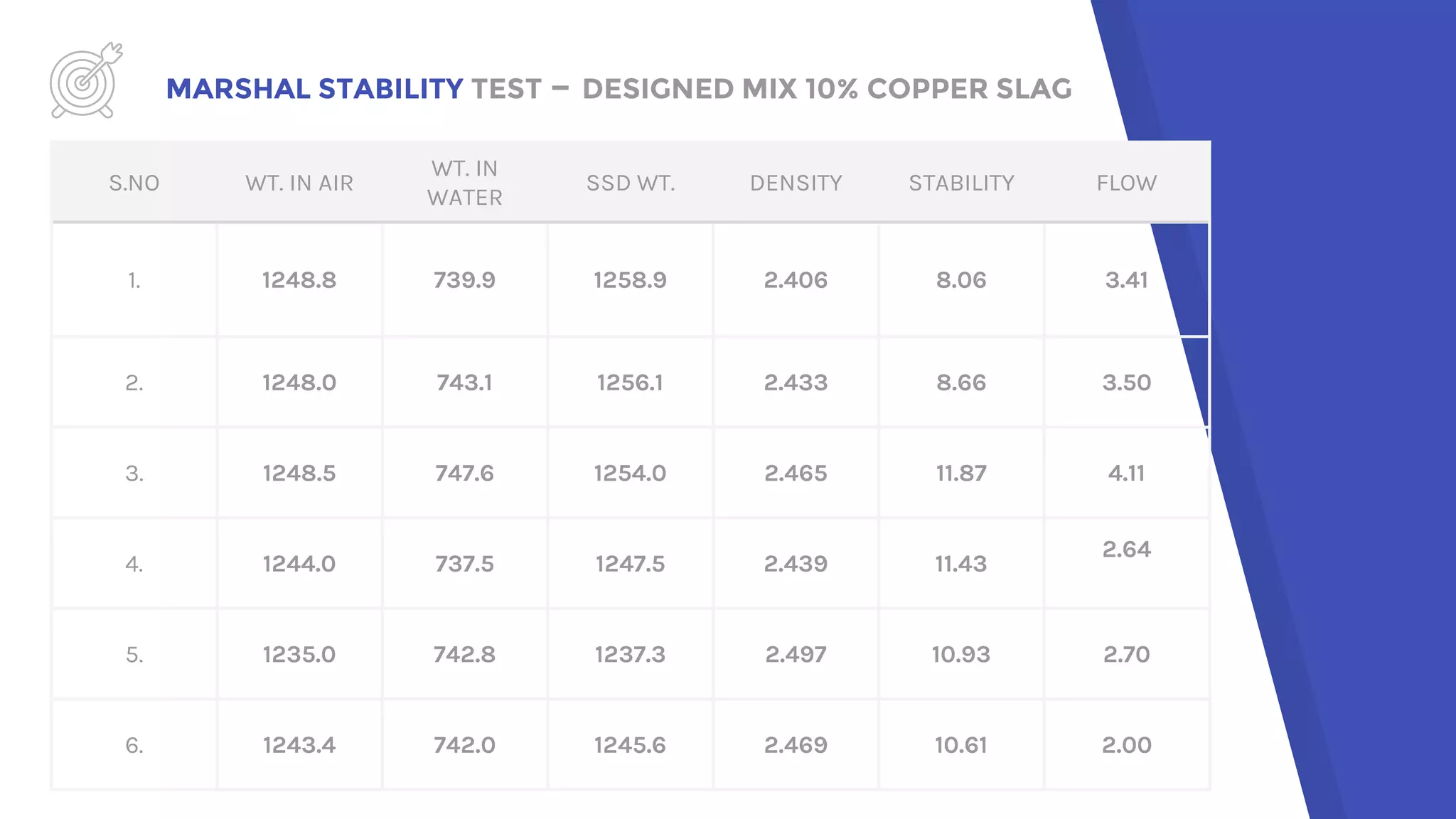

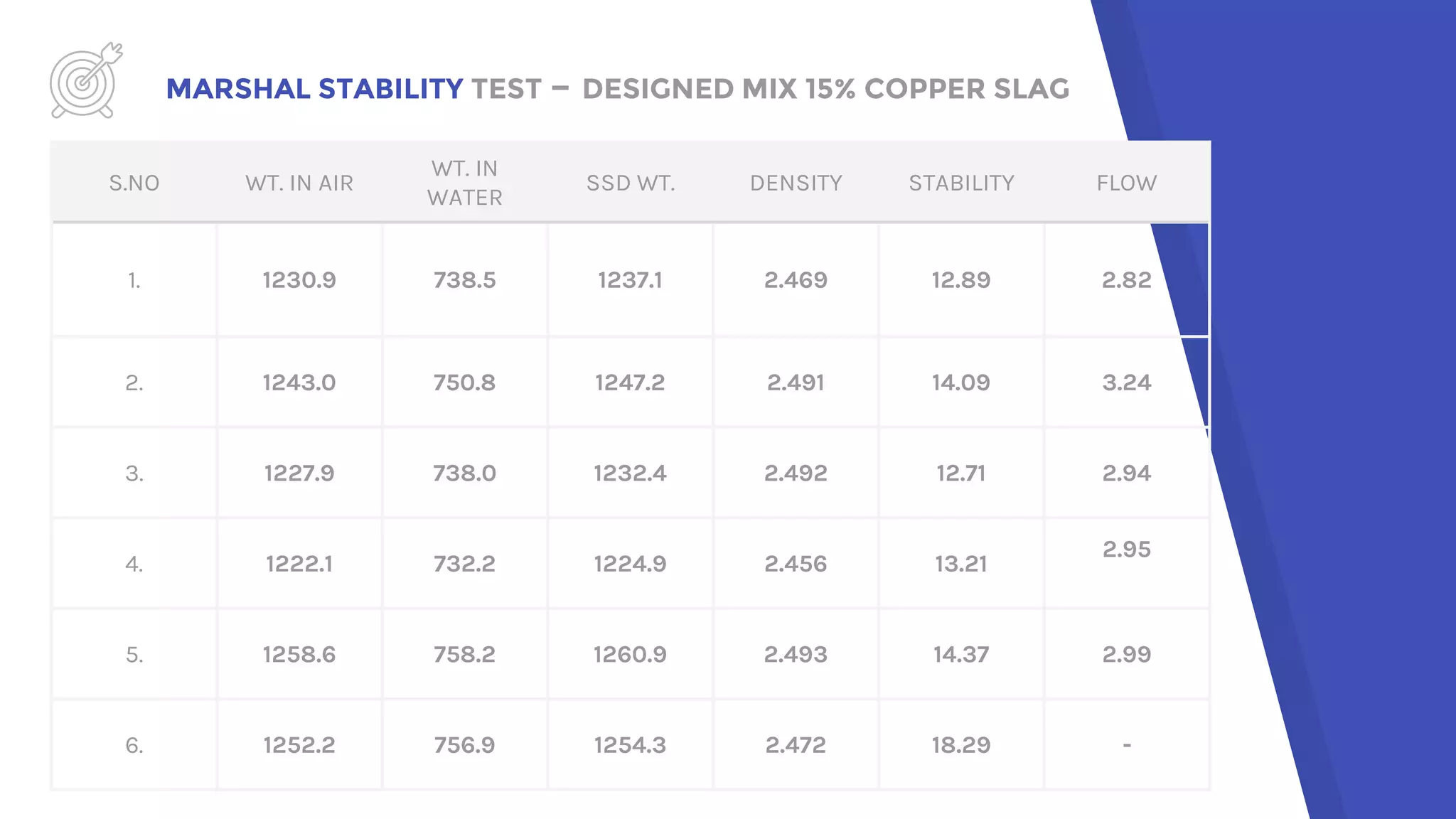

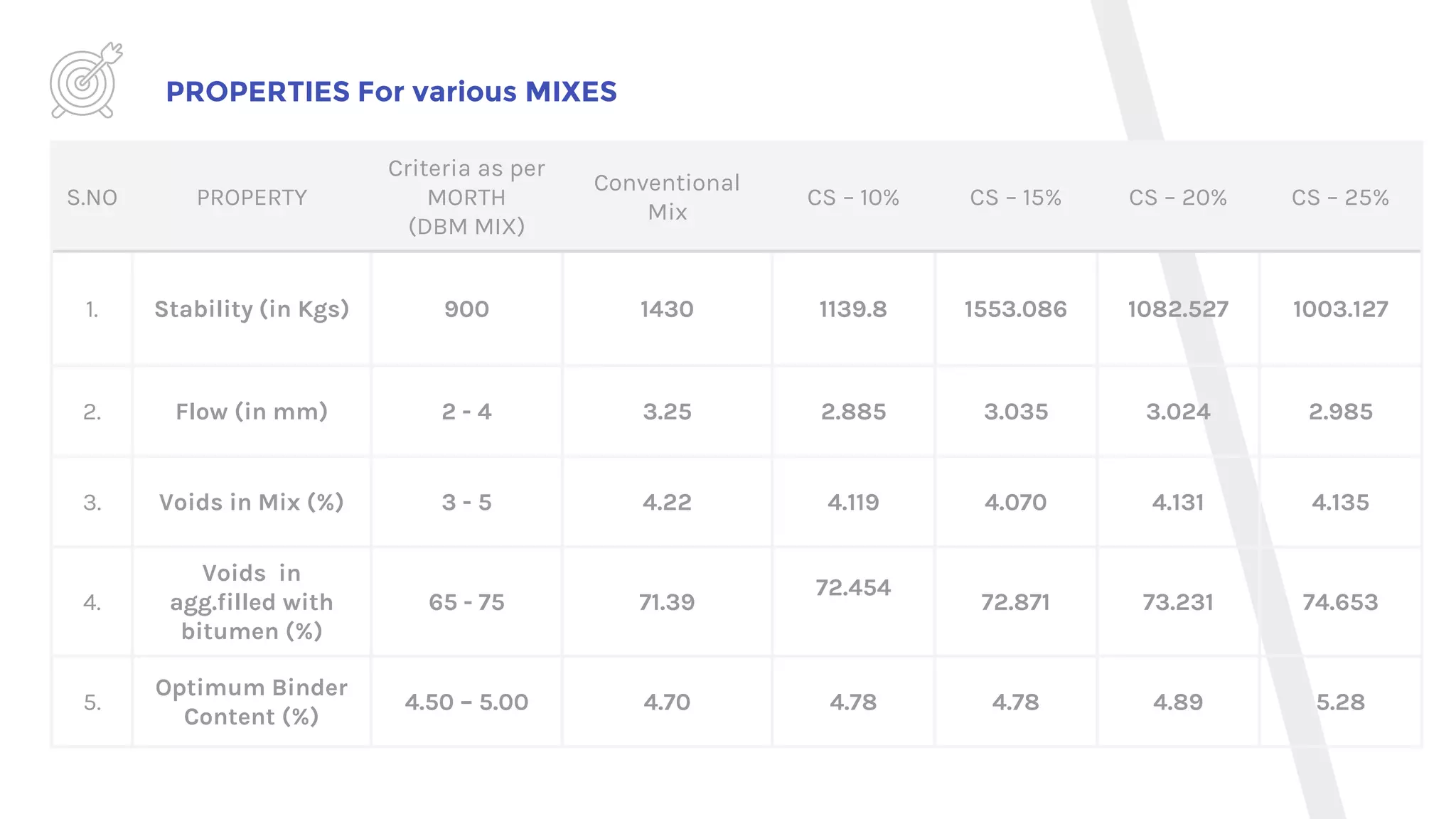

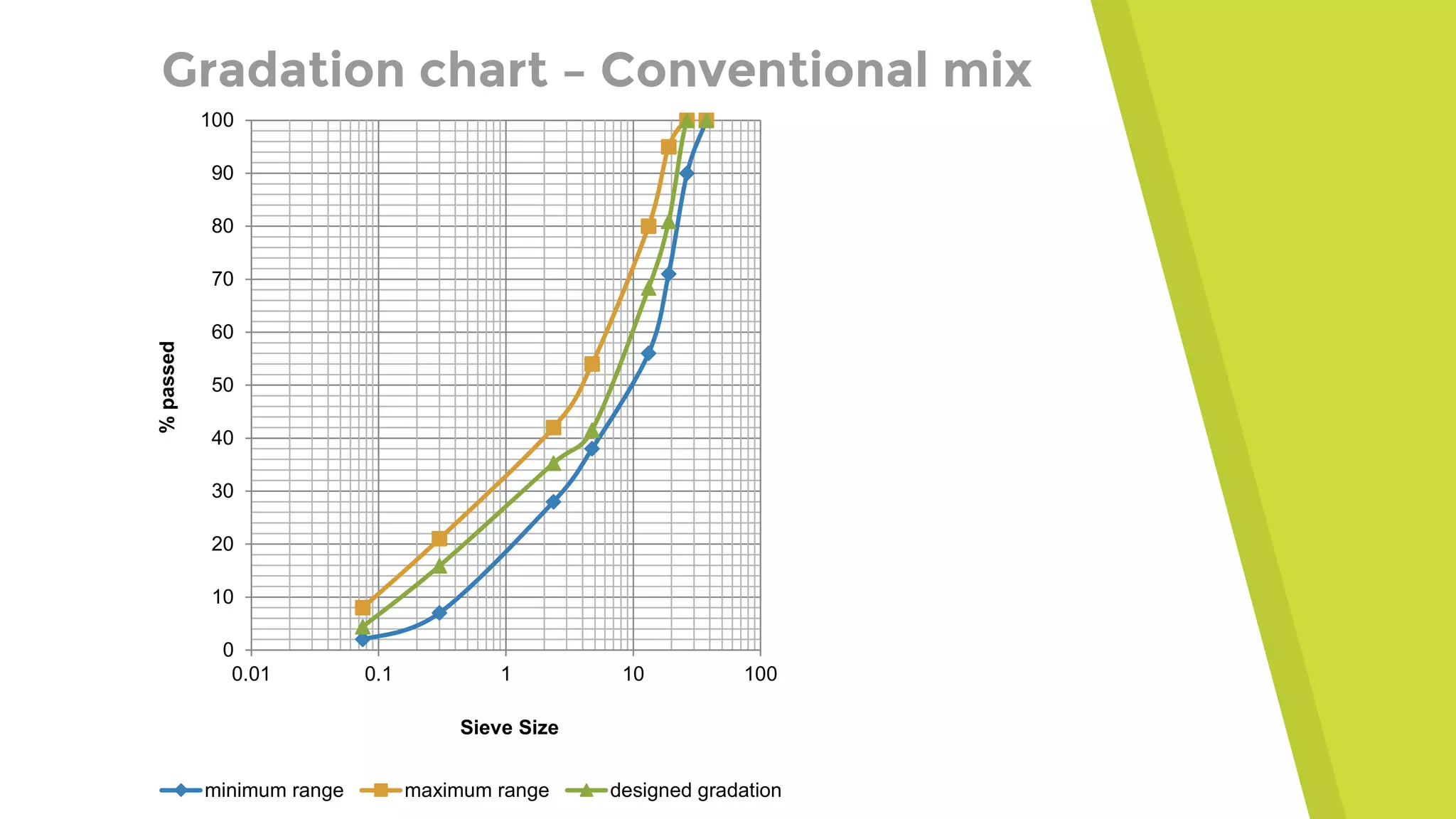

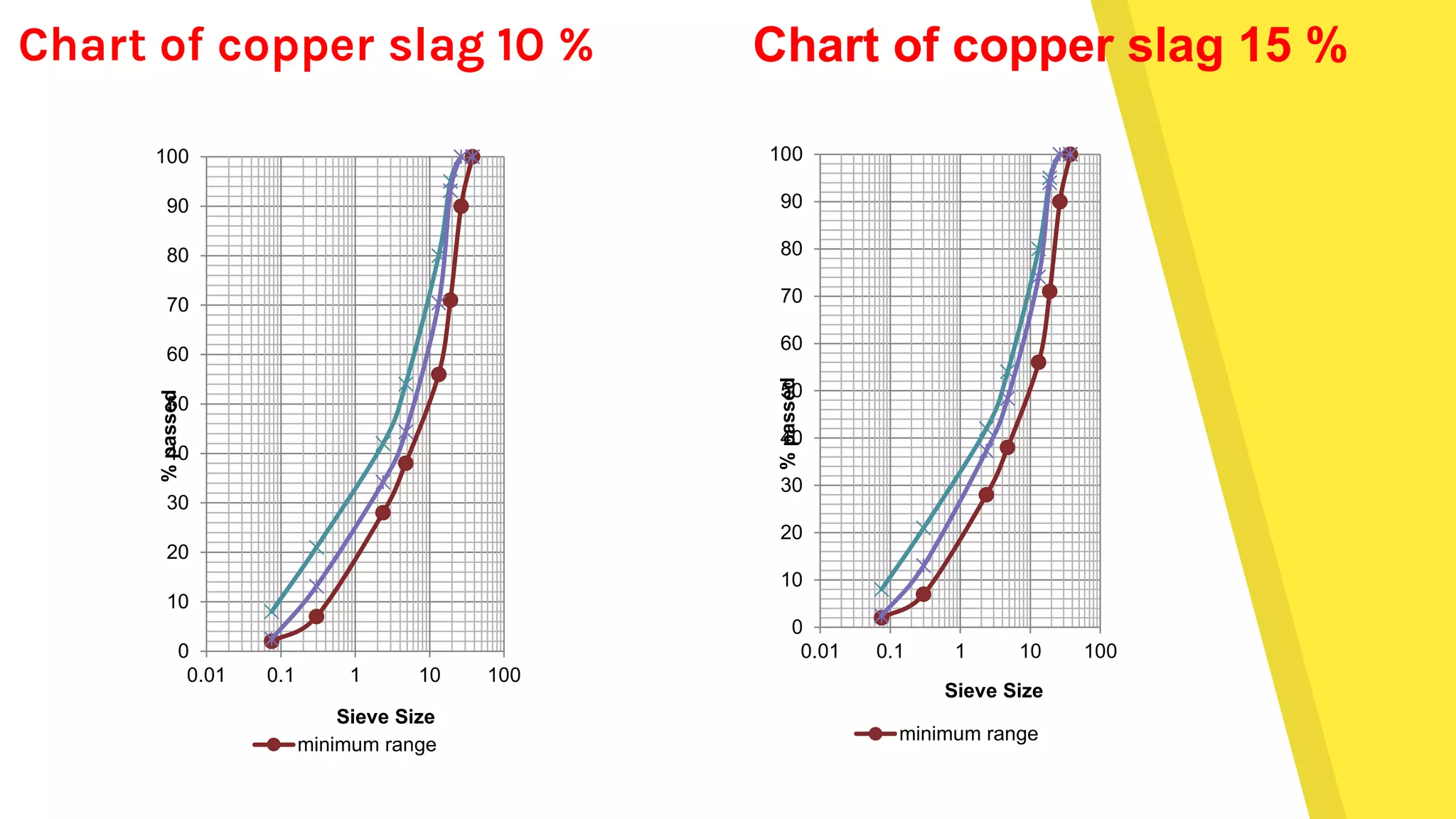

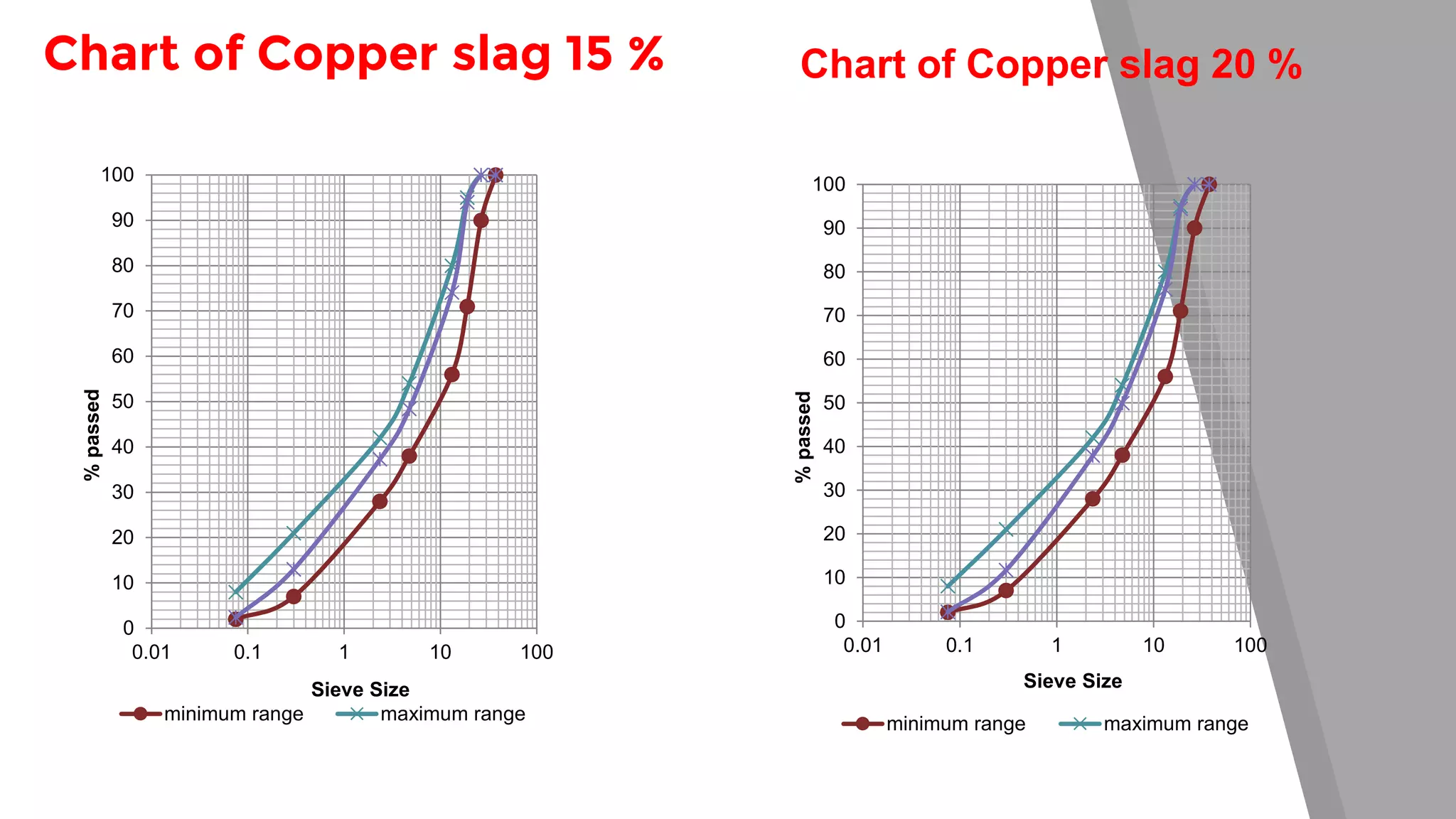

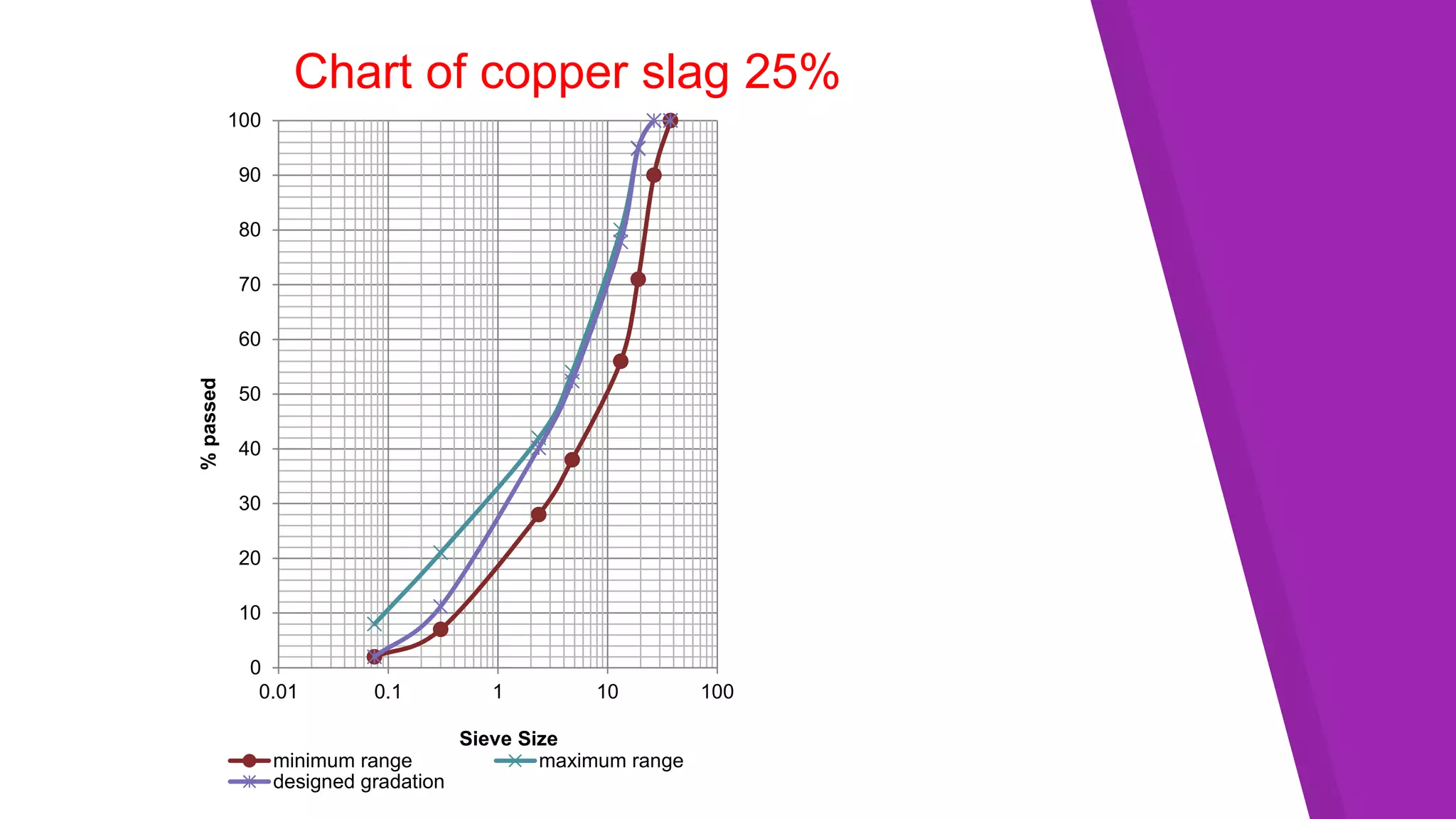

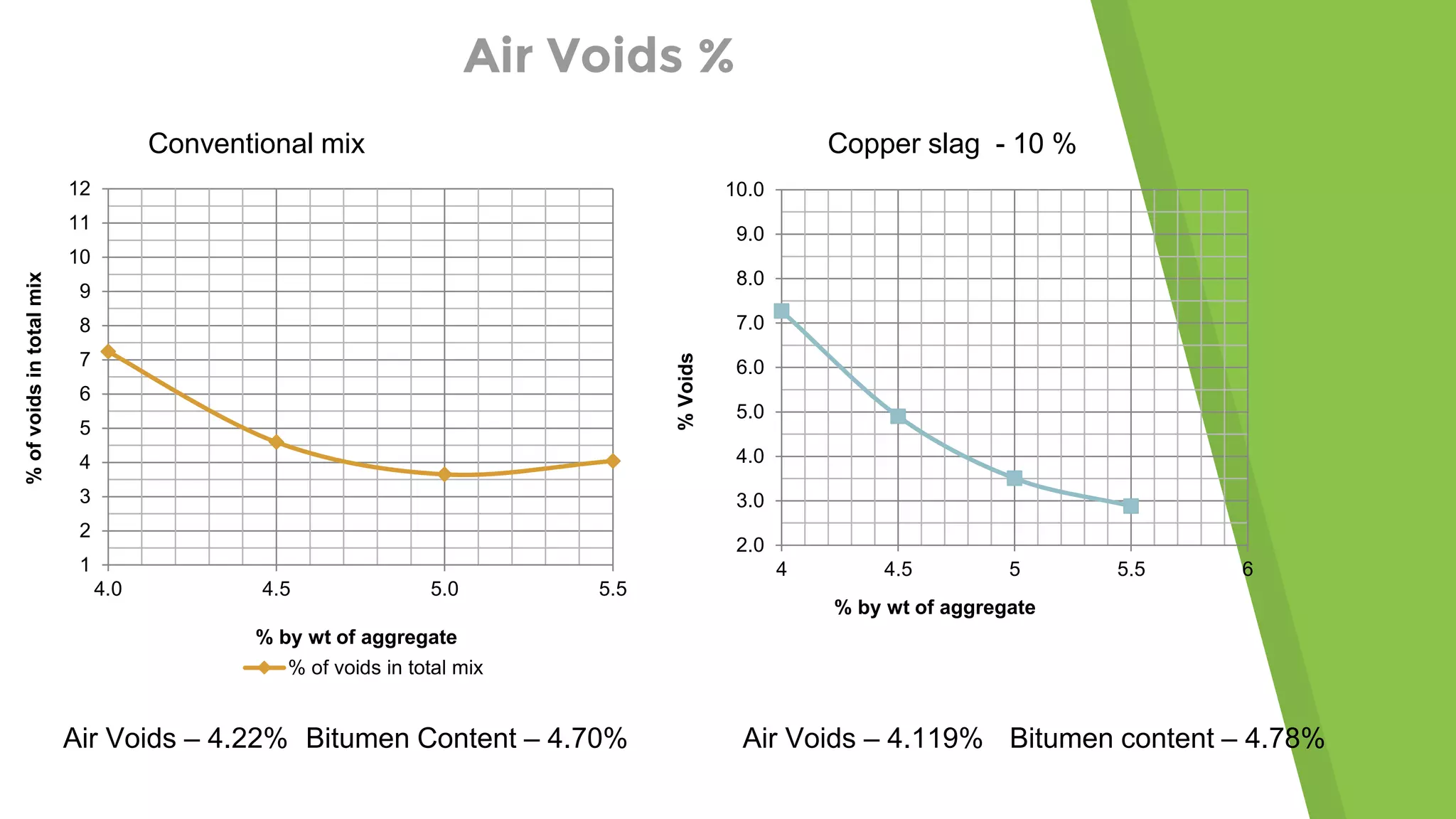

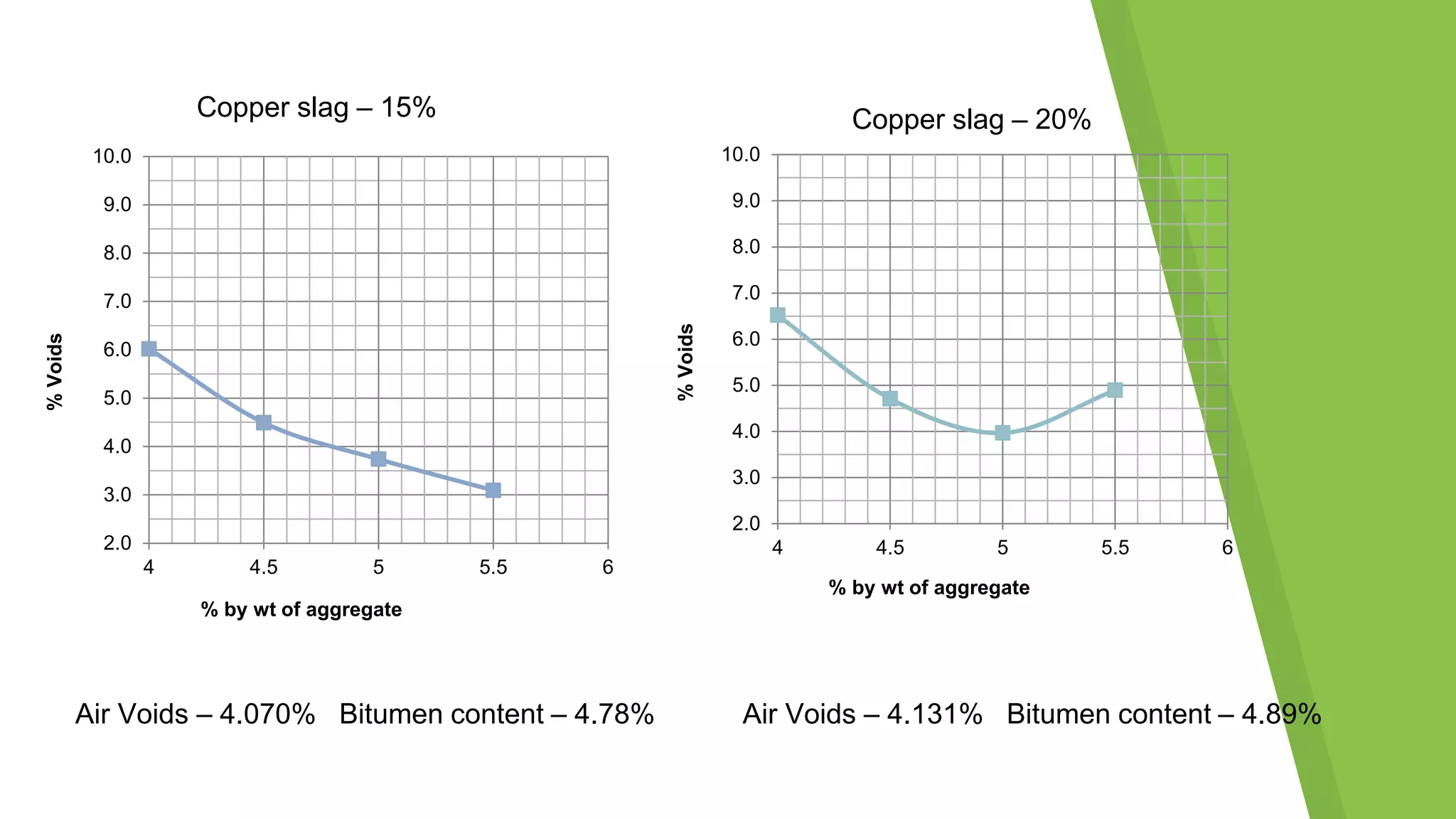

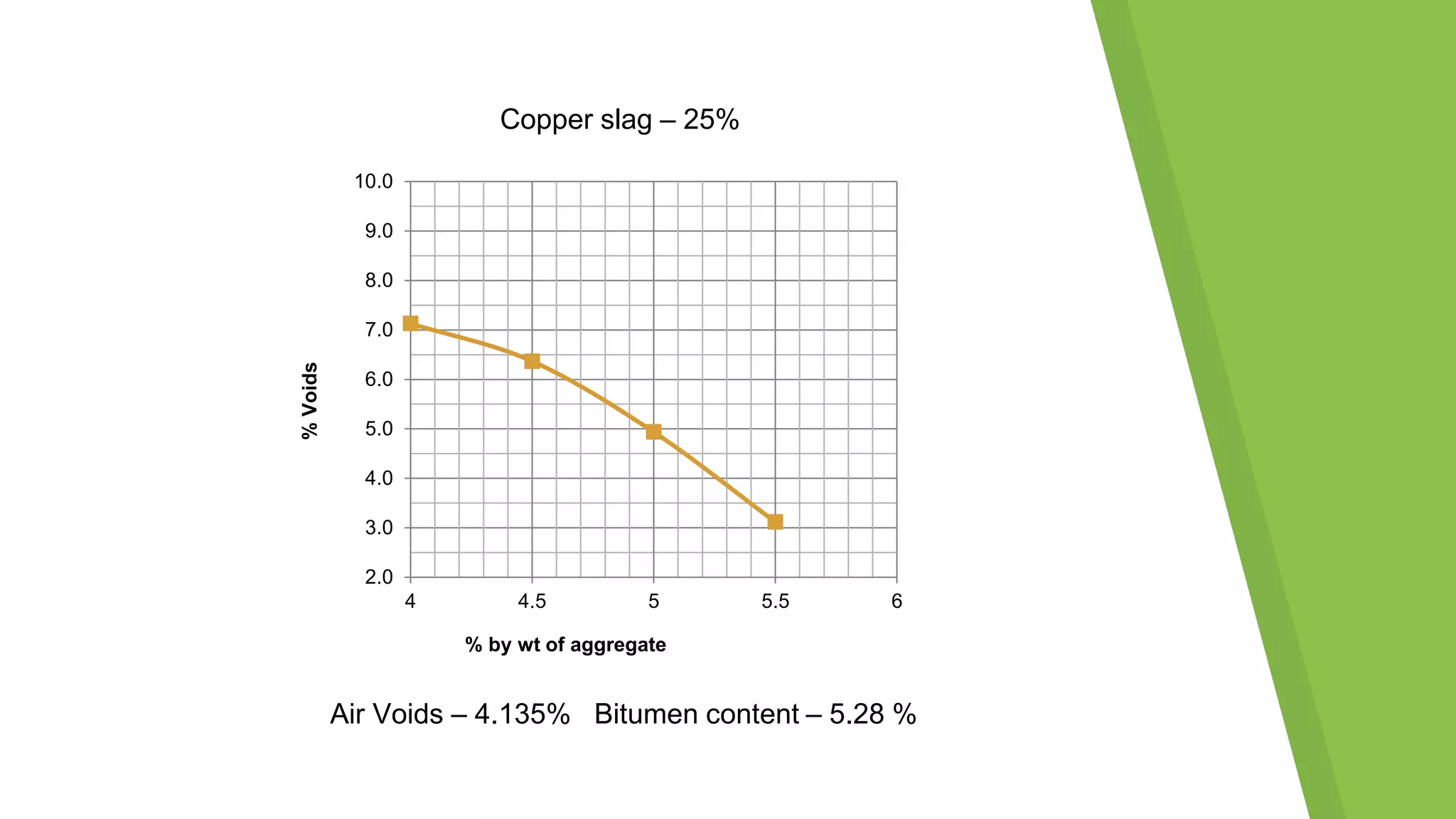

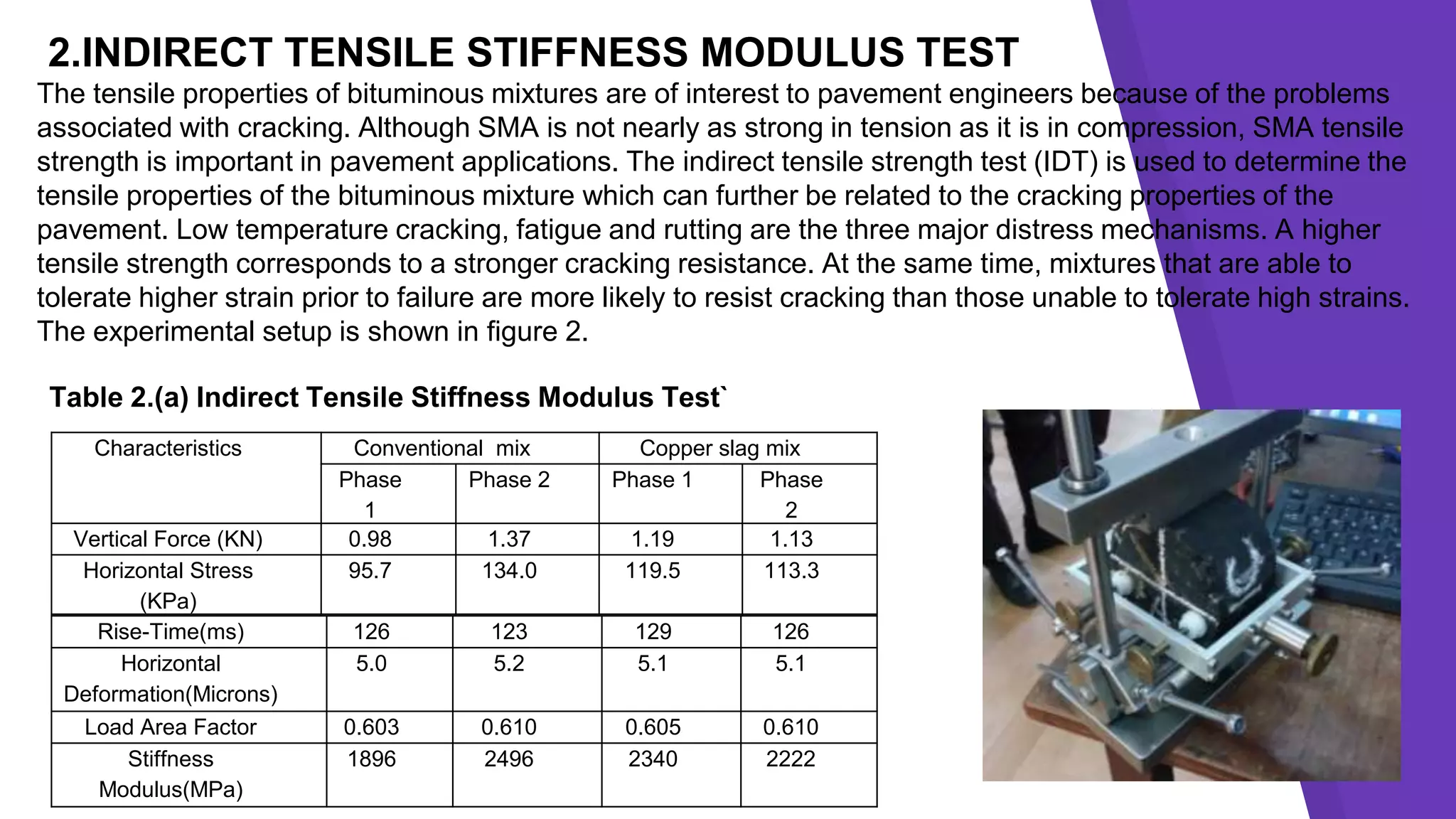

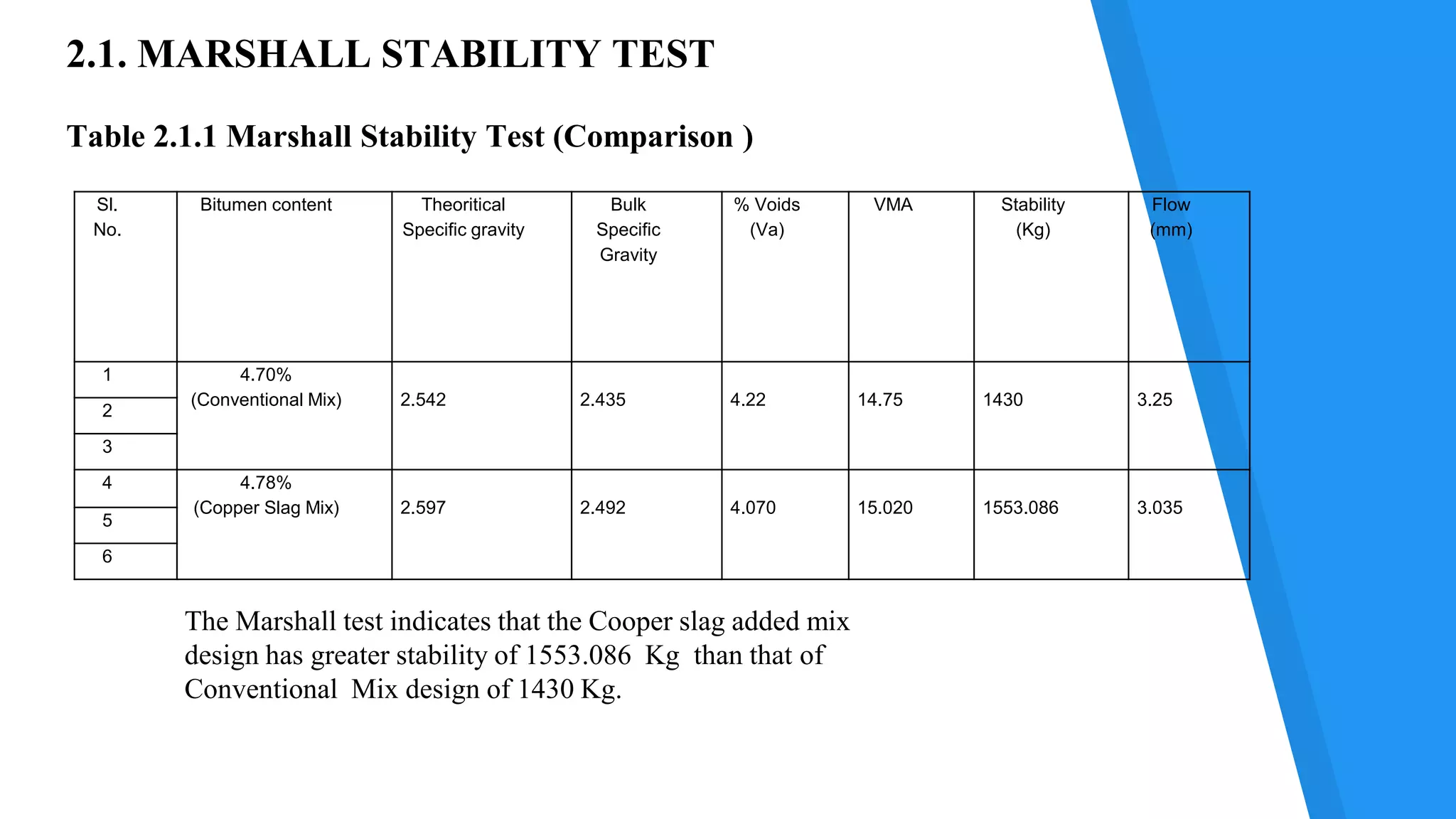

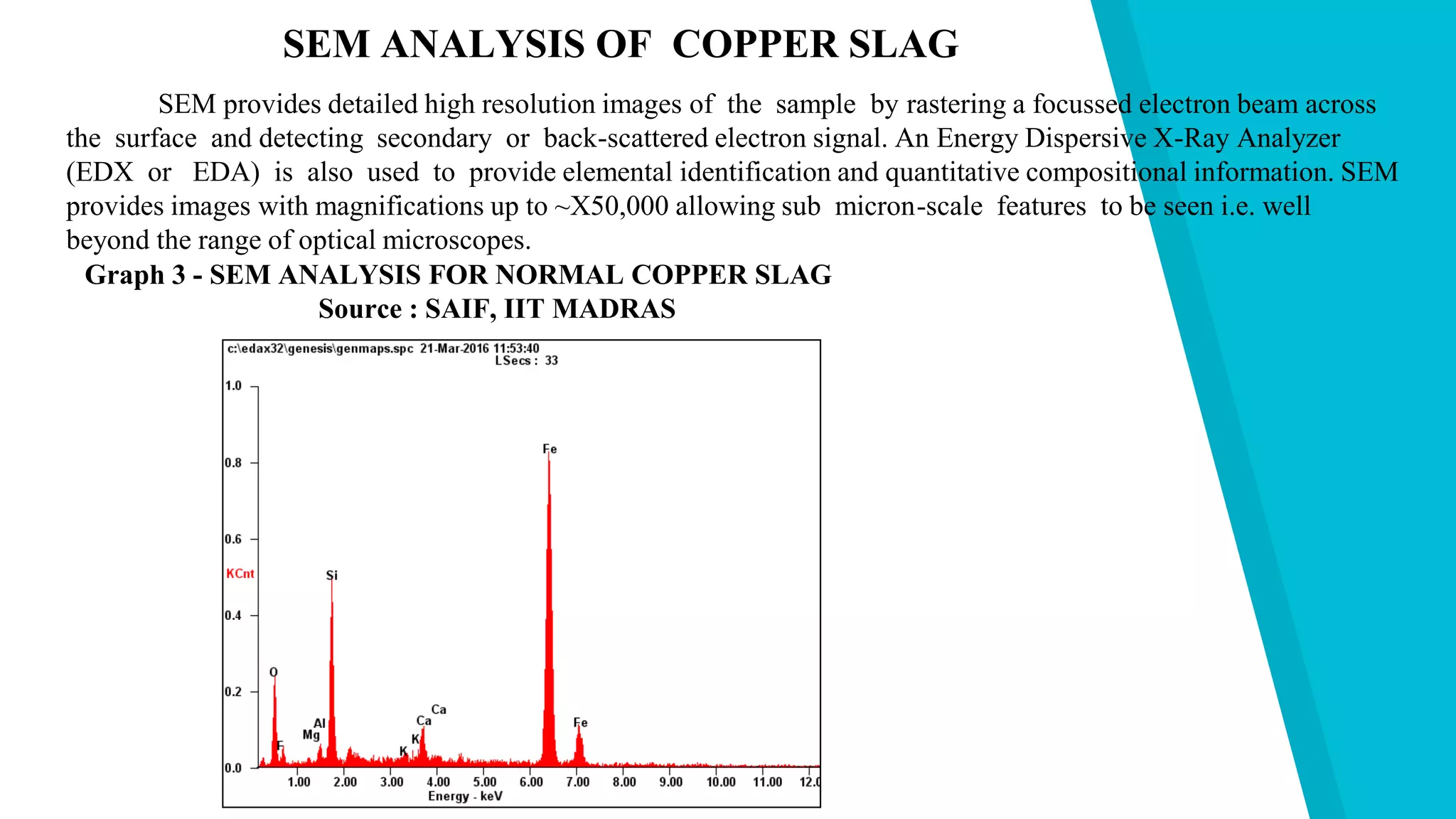

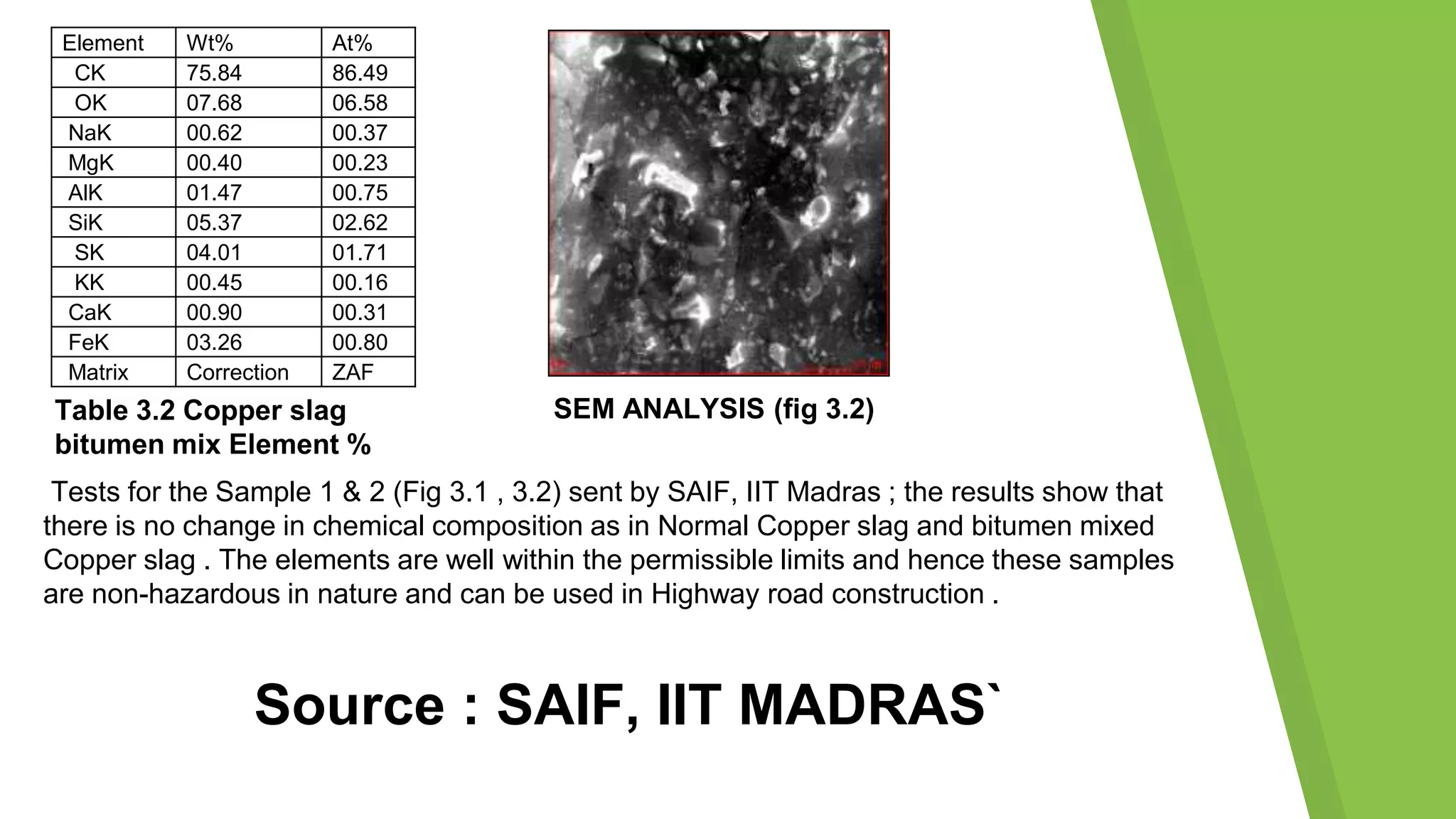

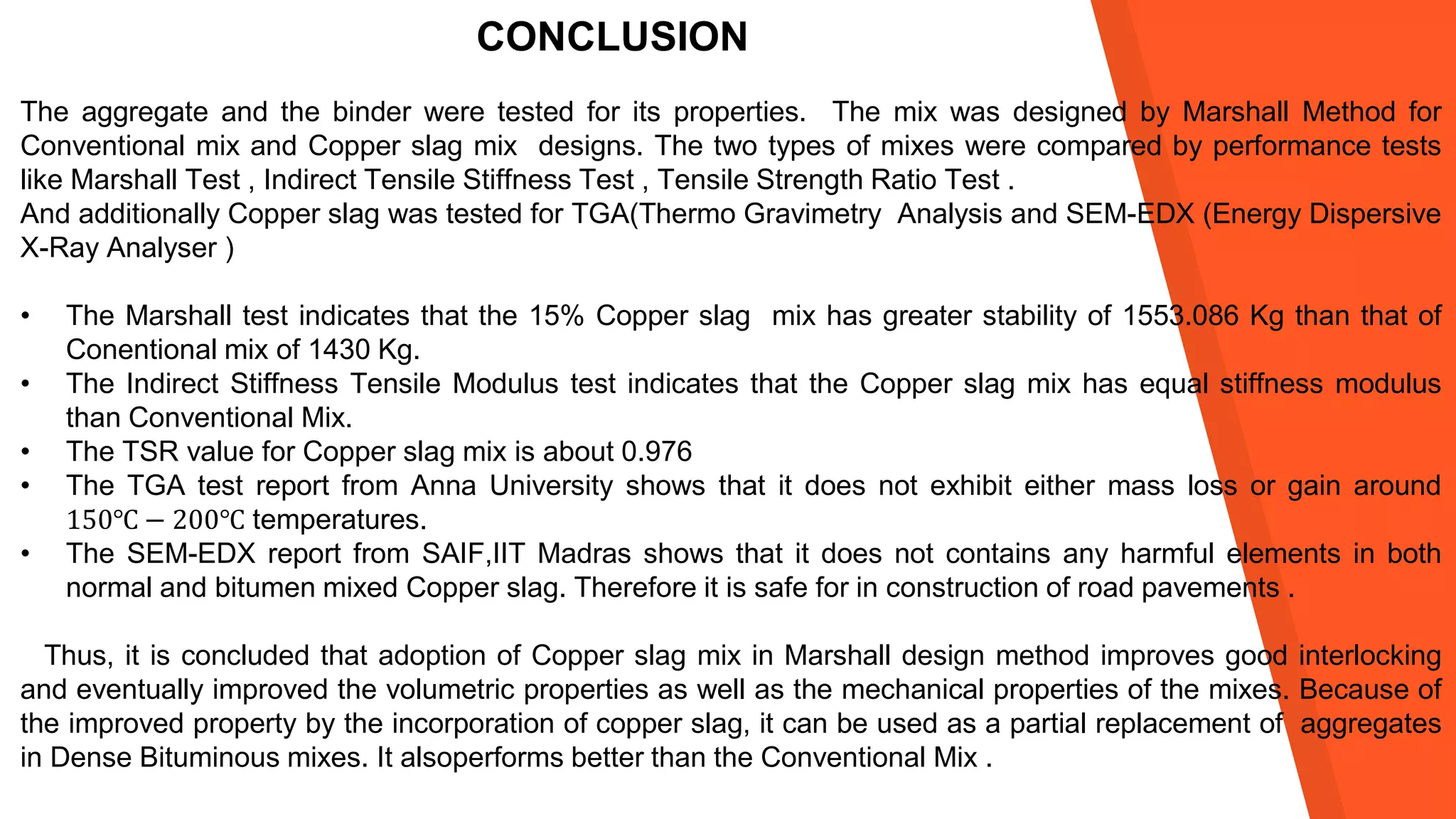

This document explores the utilization of copper slag as a partial substitute in bituminous mixes for road construction, emphasizing its potential to reduce costs and improve mechanical properties. The study includes various tests on aggregate and bitumen properties, indicating that incorporating copper slag improves stability and reduces binder content. Findings suggest that using 15% copper slag yields optimal results in terms of stability and air voids in the mix.