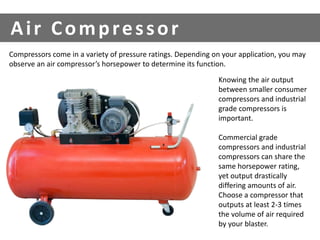

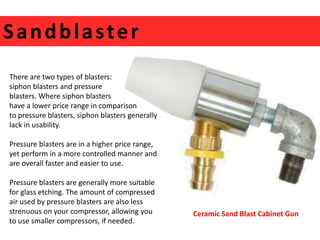

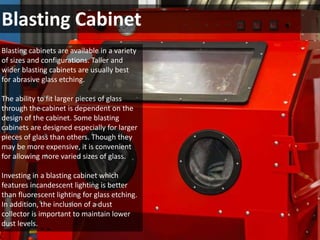

The document provides an overview of glass etching through sandblasting, detailing necessary materials, safety precautions, and equipment types including various blaster options and blasting cabinets. It emphasizes the importance of protective gear and the distinctions between surface etching, carving, and shading techniques. Additionally, it promotes 'Big A's Place' as a resource for sandblasting supplies and equipment.