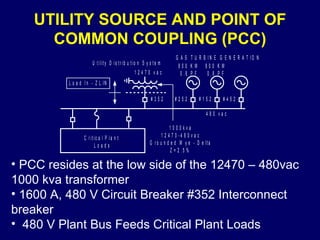

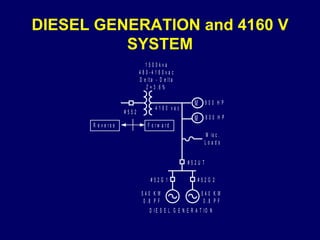

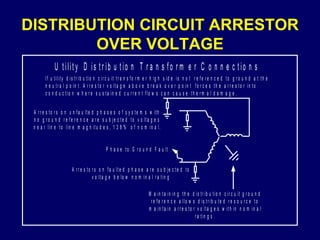

This case study describes the interconnection between an Indian Basin Gas Plant and the local utility. The interconnection provides benefits like increased reliability and reduced operating costs for the plant. Sensors and relays including the SEL-351 multifunction microprocessor relay are used for protection, monitoring and control of the interconnection. Event reports and phasor plots from the relays allow analysis of disturbances to improve the protection system.