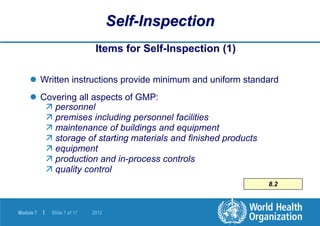

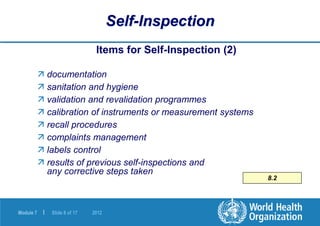

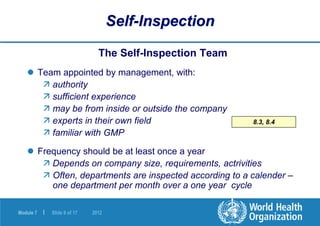

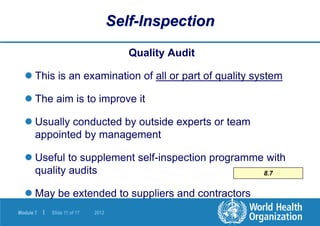

The document discusses the principles and objectives of self-inspection within a quality management system, emphasizing its role in ensuring compliance with Good Manufacturing Practices (GMP). It outlines the necessary components for an effective self-inspection program, including the formation of an unbiased inspection team, documentation procedures, and follow-up actions on identified issues. Additionally, it highlights the importance of quality audits, supplier evaluations, and the continuous improvement of the self-inspection process.