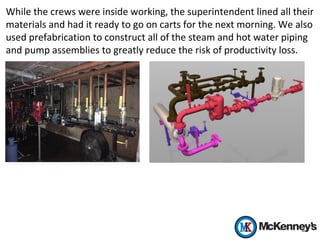

McKenney's Building Performance Solutions upgraded an inefficient heating system in a Georgia maximum security prison through a comprehensive energy savings performance contract. The project involved the conversion from steam to hot water heating, addressing multiple challenges including safety protocols and scheduling for various trades within a confined space. The successful execution included specialized safety training, on-site supervision by correction officers, and pre-planning to ensure seamless project completion ahead of schedule.