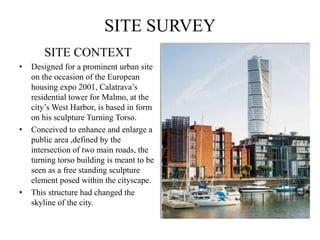

The Turning Torso is a 190-meter residential skyscraper located in Malmo, Sweden that was designed by architect Santiago Calatrava. Some key details:

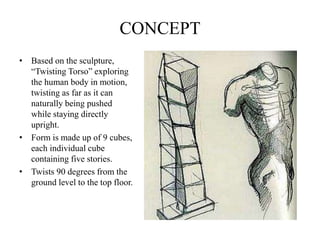

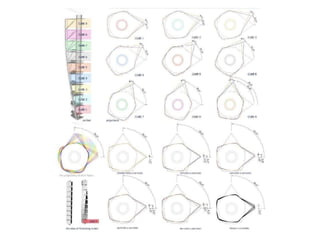

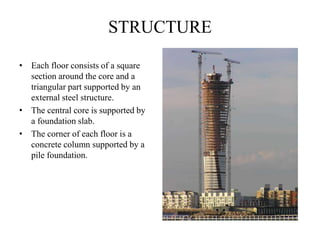

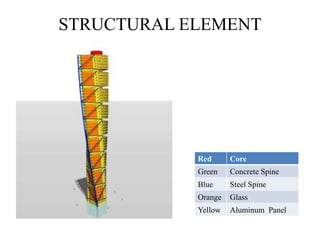

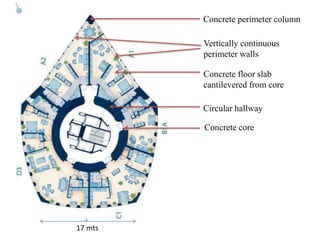

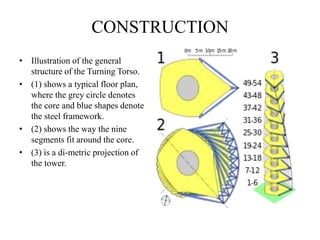

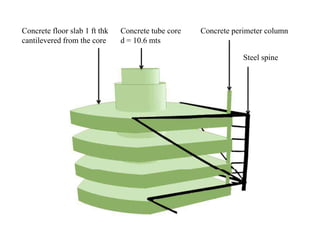

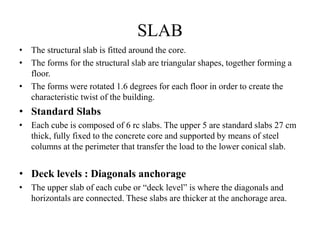

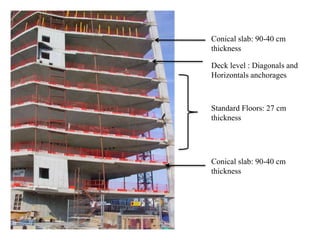

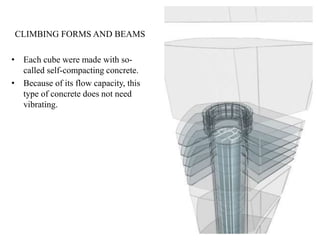

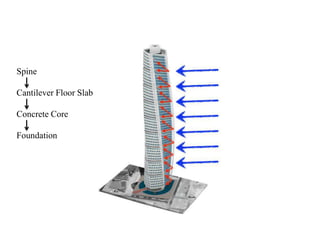

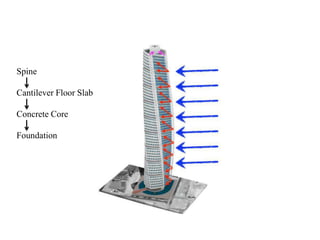

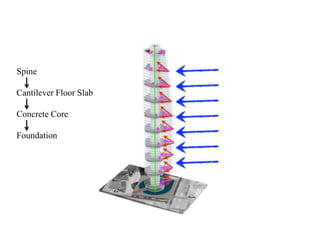

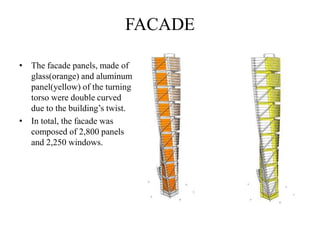

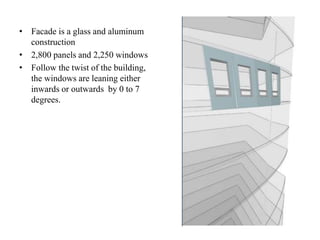

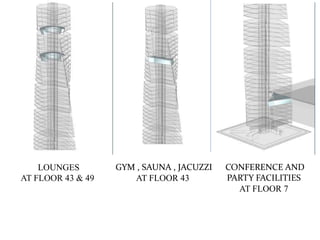

- It has a twisting form composed of nine concrete cubes that twist 90 degrees from the base to the top.

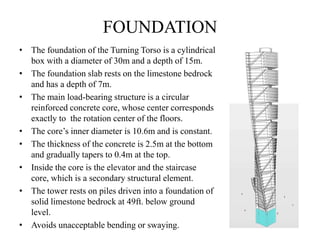

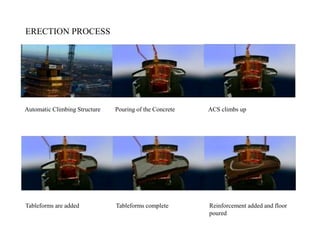

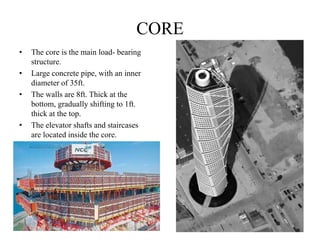

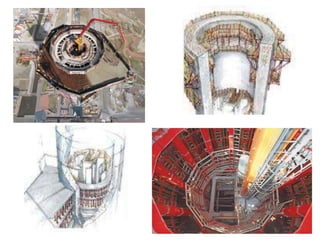

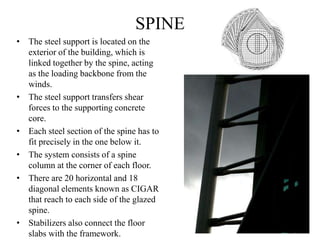

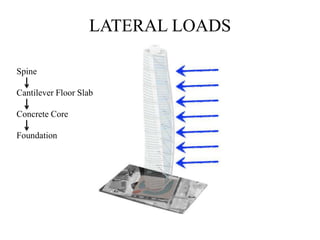

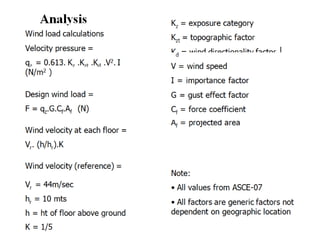

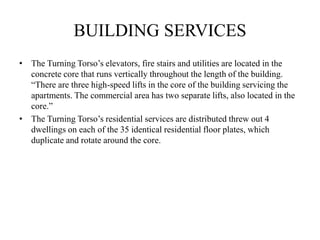

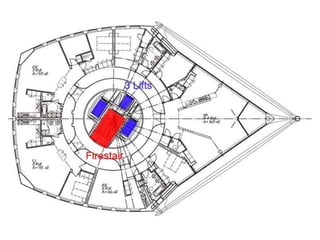

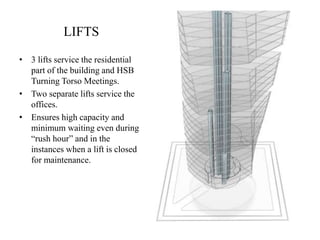

- The central concrete core provides structural support, containing elevators and staircases. An exterior steel exoskeleton transfers wind loads and allows the concrete floors to cantilever.

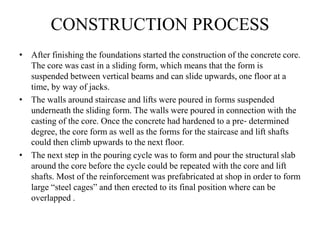

- Construction began in 2001 and was completed in 2005, using a unique climbing form system to pour the concrete floors which rotated 1.6 degrees with each level.

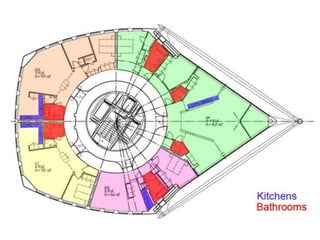

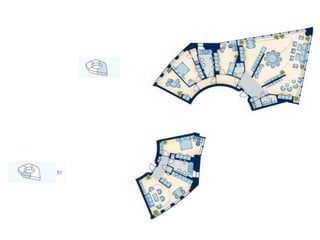

- The skyscraper contains residential units and office space and utilizes sustainable design principles