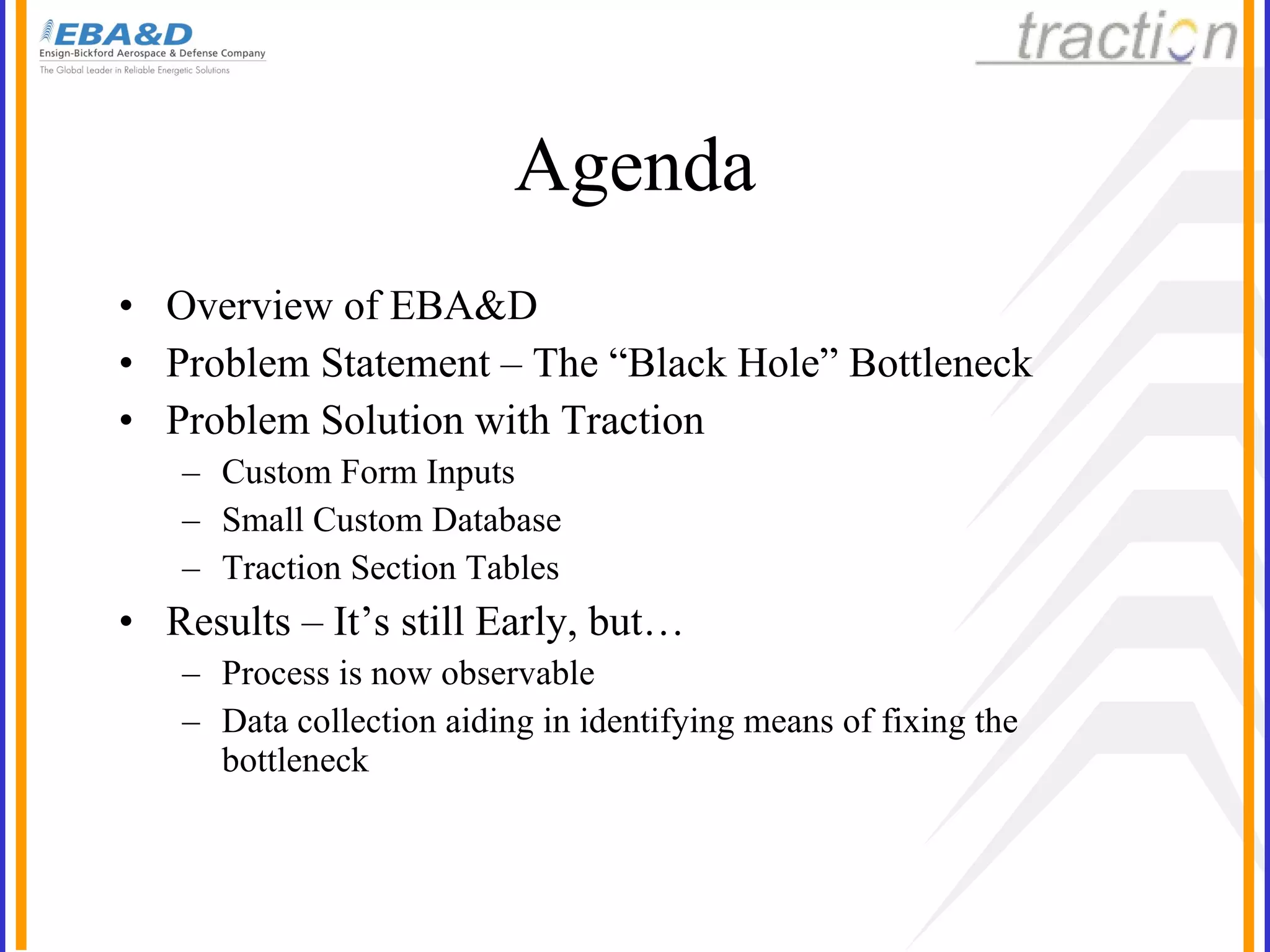

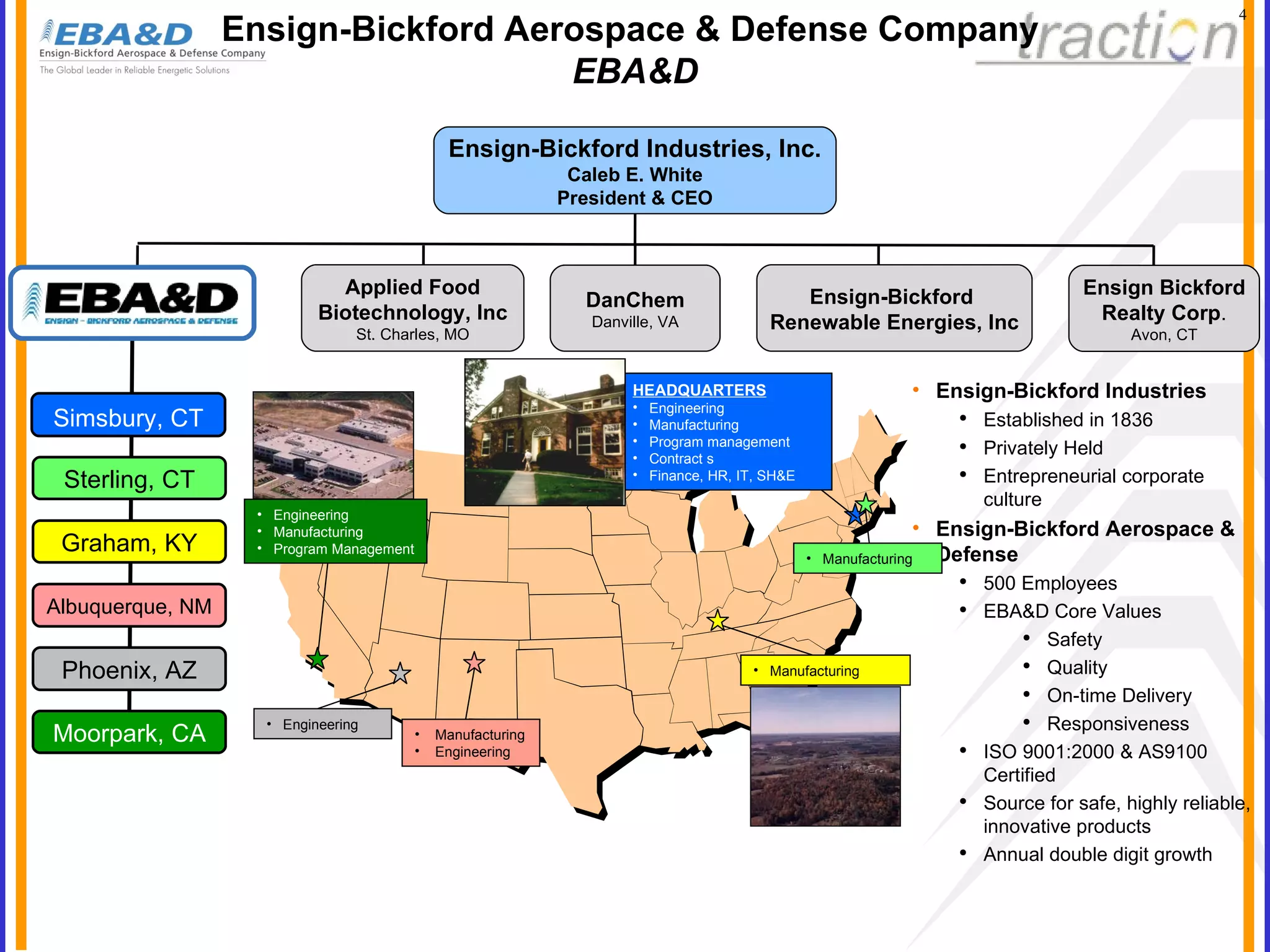

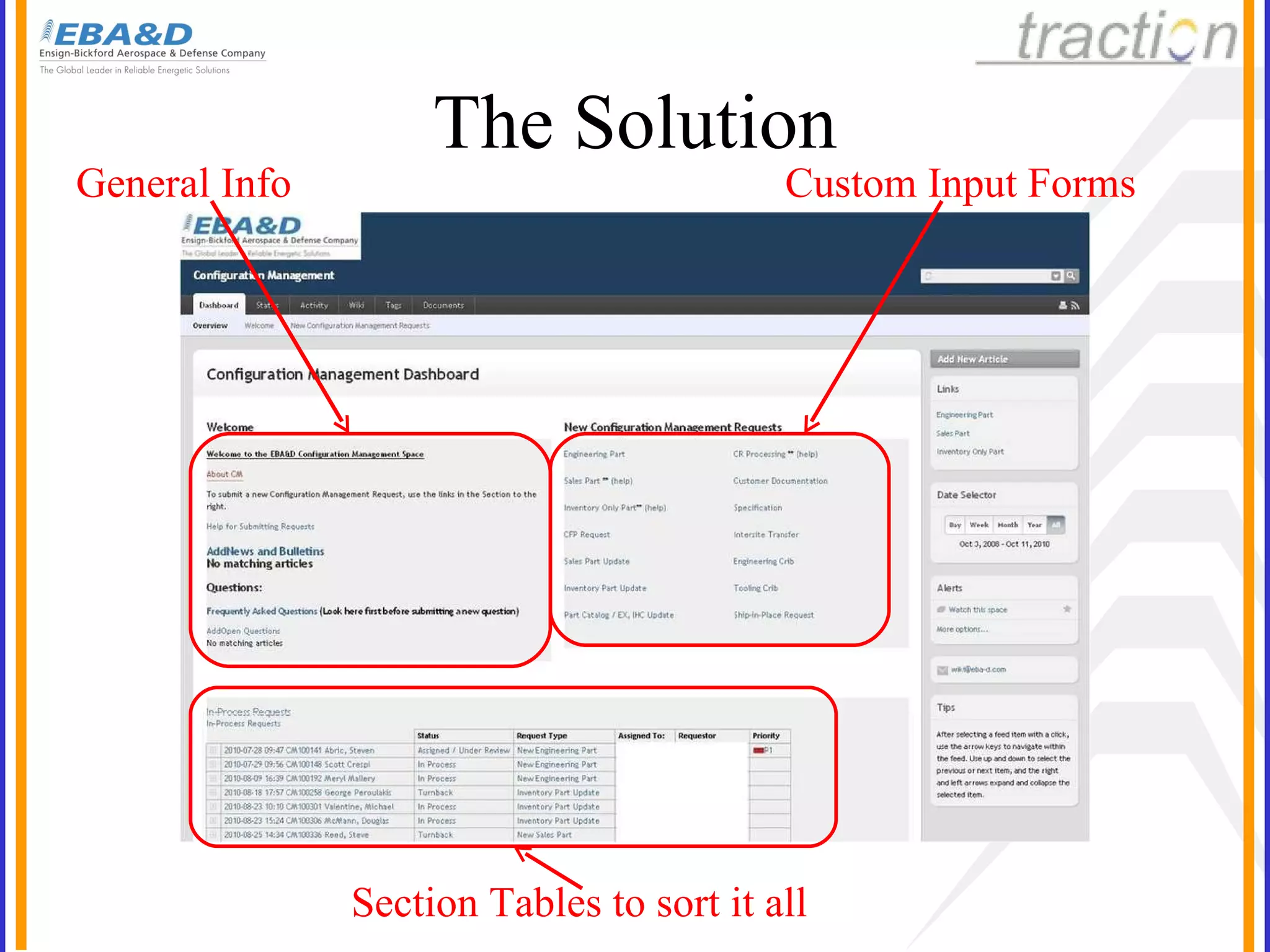

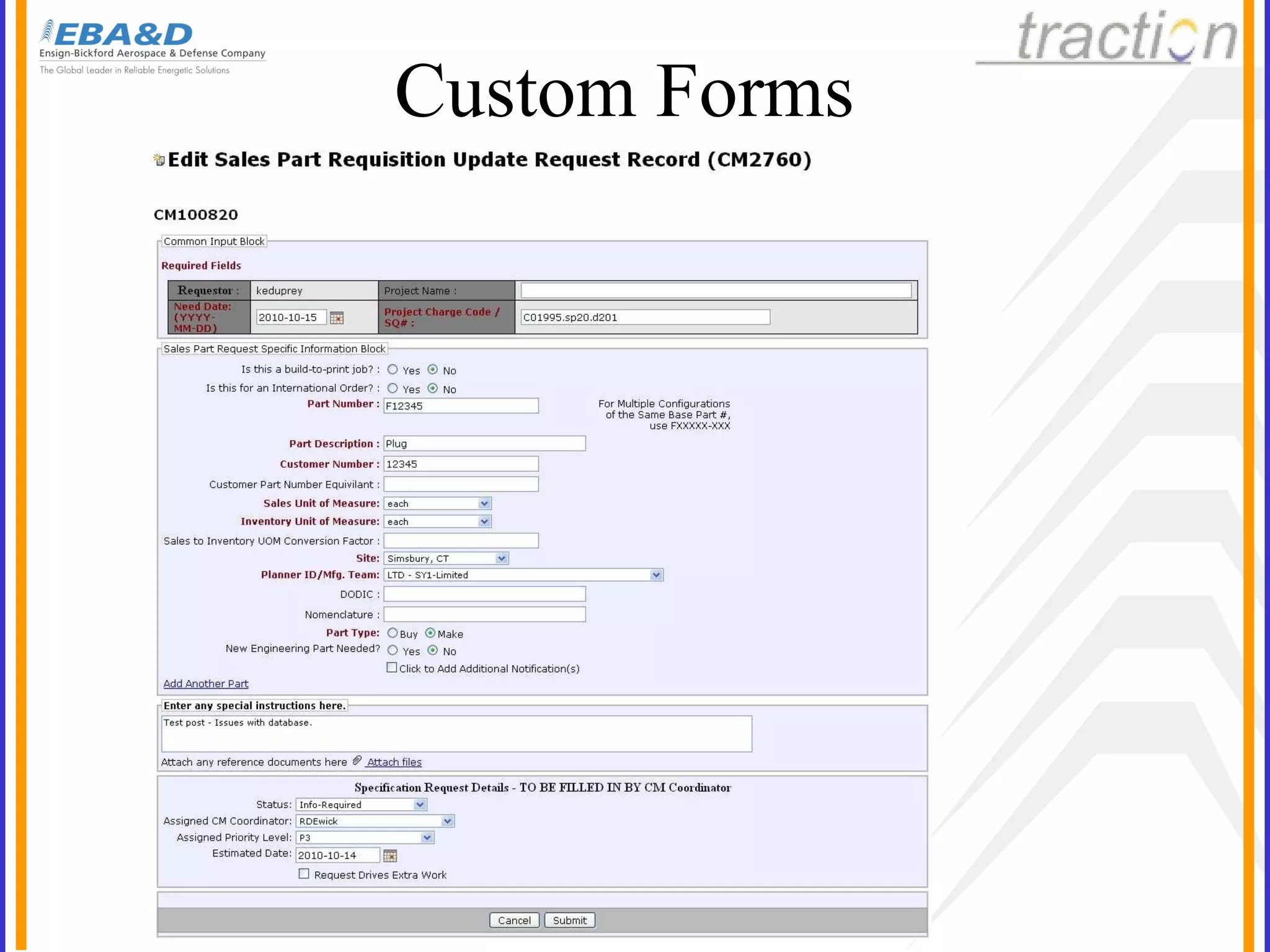

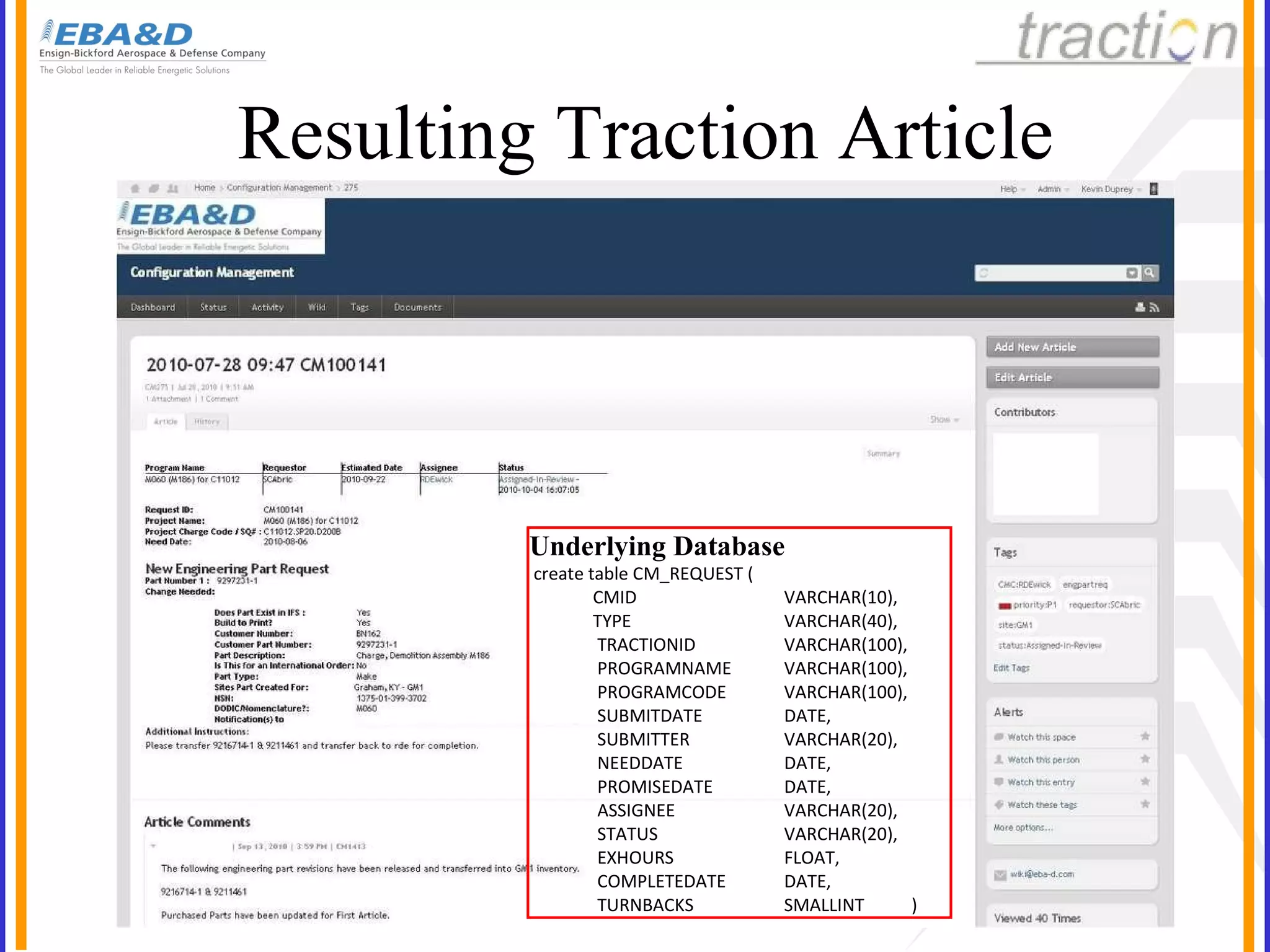

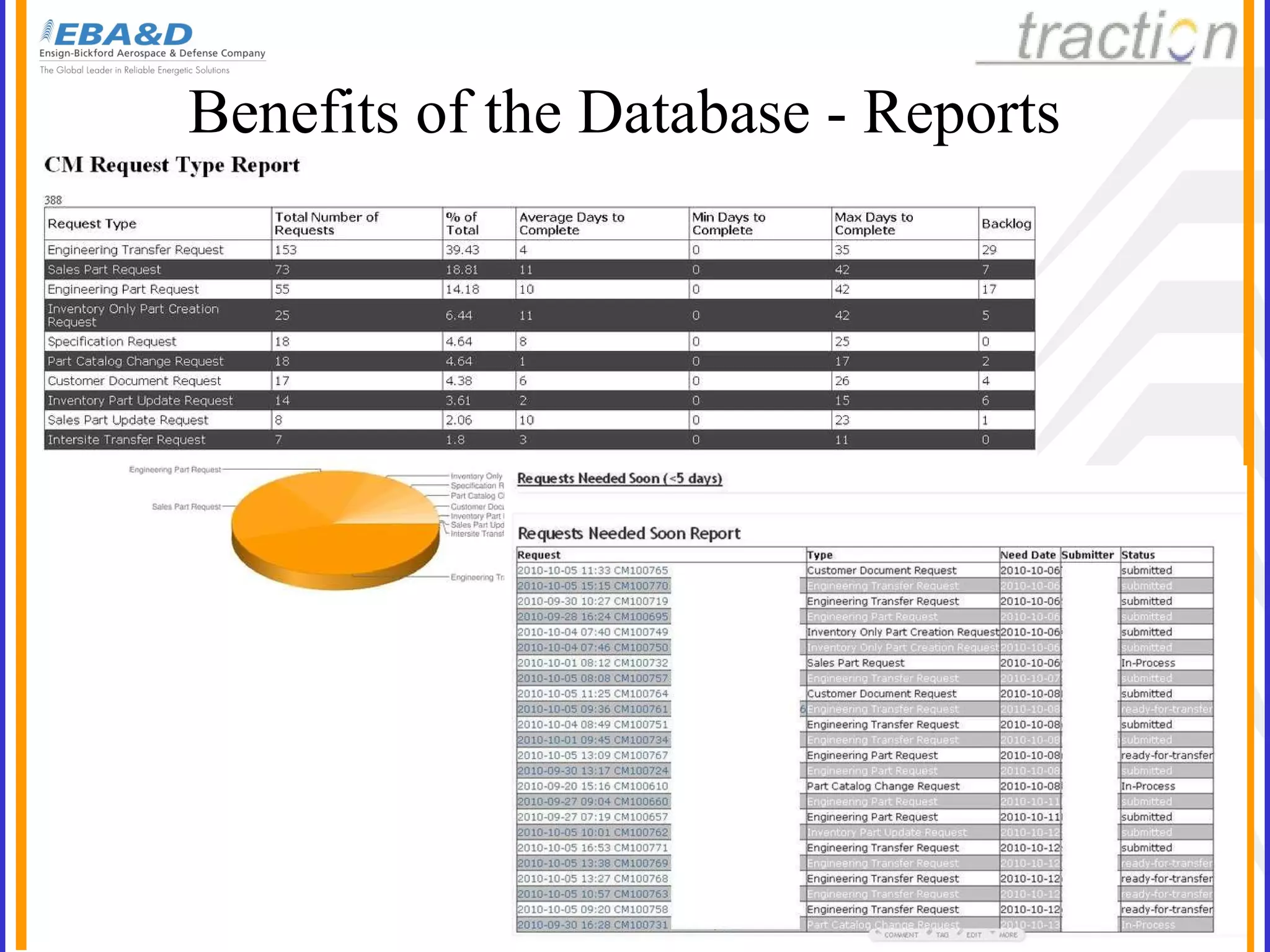

The document discusses how Ensign-Bickford Aerospace & Defense tackled a 'black hole' bottleneck issue by implementing traction software with some customization, specifically through the creation of custom input forms and a small database. This solution has made the process more observable, allowing for better data collection and prioritization of requests, ultimately aiding in reducing inefficiencies. The implementation has shown early positive results, with simplified input processes and improved visibility into workloads.