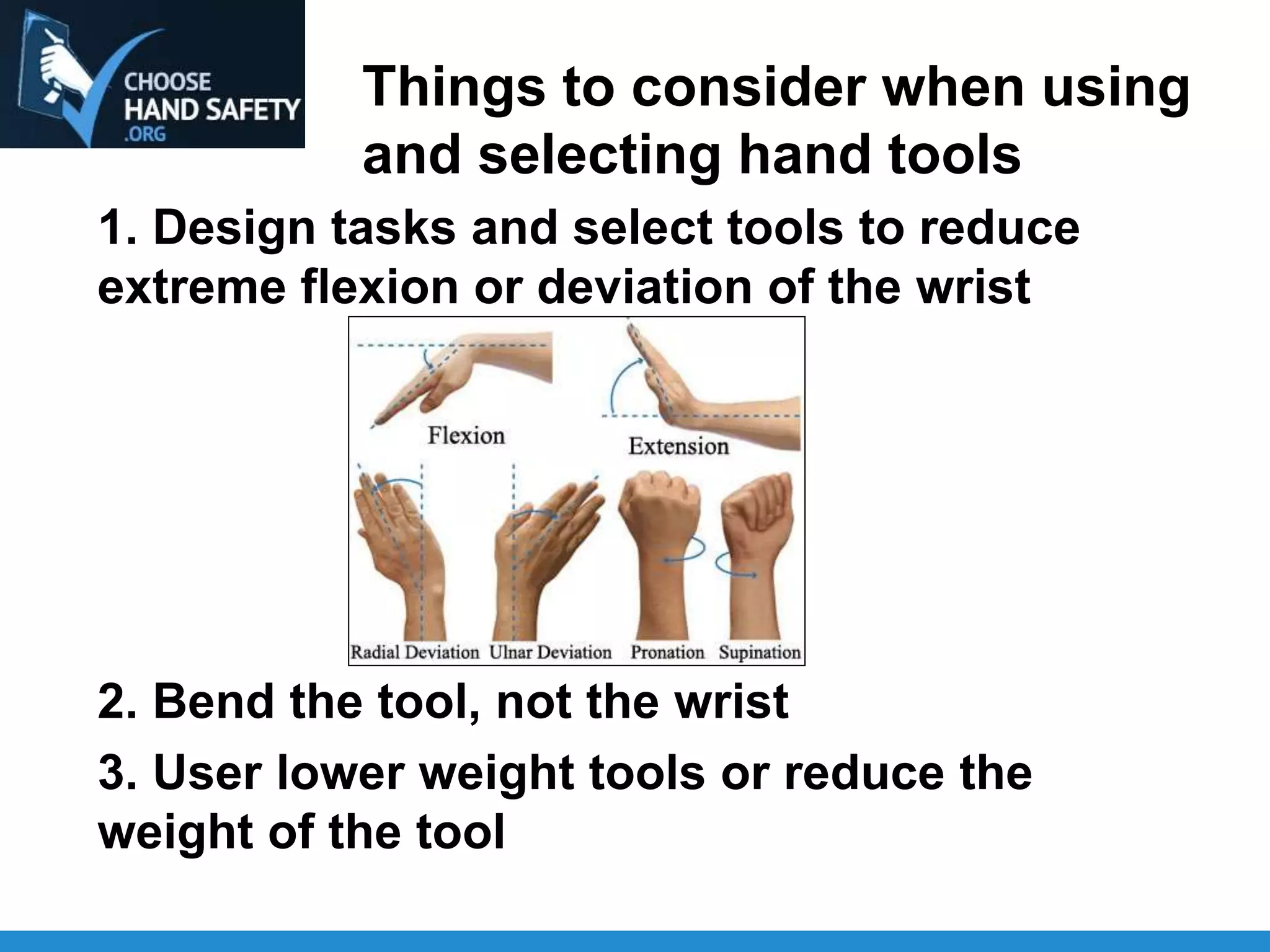

The document provides guidance on hand tool use and selection to prevent hand and wrist injuries in construction. It lists factors that can cause injuries like repetitive motions, inappropriate tools, vibration, and poor workstation design. The key considerations for safe tool use are to reduce bending of the wrist, use lighter tools, avoid stress on pressure points, and make sure tools fit the hand properly. Proper grip type and isolating hands from heat, cold, and vibration can also help prevent injuries from tool use.